Metal wiring film, manufacturing method thereof and thin film transistor

A thin film transistor and metal wiring technology, applied in the field of electronic display, can solve the problems of increasing metal wiring film resistance, corrosion, affecting the quality of the display panel, etc., and achieves the effect of eliminating potential difference and avoiding electrolytic corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

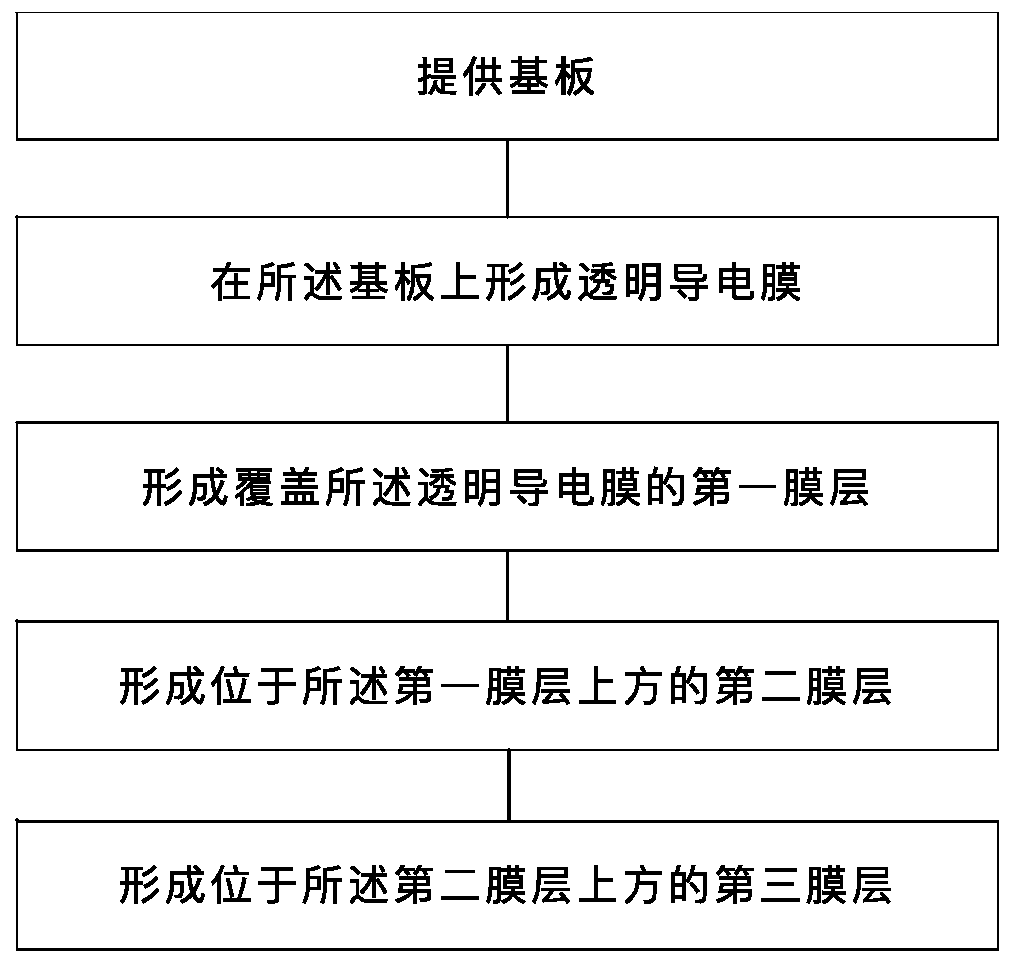

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention. In the figures, structurally similar elements are denoted by the same reference numerals.

[0033] First, the prior art is briefly described. The wiring structure in the existing display panel generally includes a tin-doped indium oxide film (Indium Tin Oxide, ITO) and a metal wiring film located above the ITO film. The metal wiring film generally includes molybdenum-niobium alloy films (Mo-Nb) on both sides and aluminum-niobium alloy (Al-Nd) between the mol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com