Method for preparing low GI recombinant highland barley grain

A technology for highland barley and highland barley powder, which is applied in the field of preparation of low GI reconstituted highland barley granules, can solve the problems of rough taste, unable to meet the requirements of food color, fragrance, and few, etc., and achieves lowering of blood sugar index, retention of slow digestion characteristics, and gelatinization. low degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

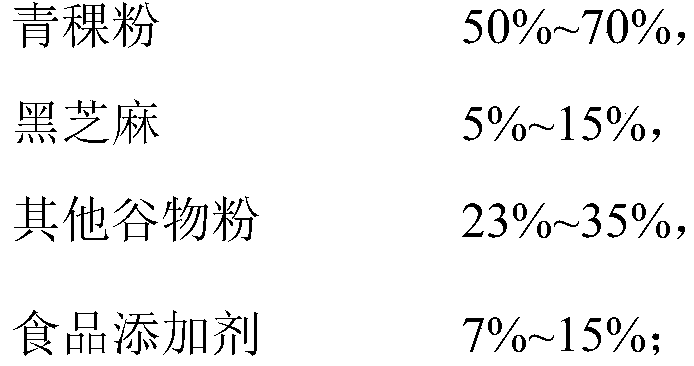

[0051] Mixed powder formula: 450g highland barley powder, 100g quinoa flour, 100g oat flour, 50g flower kidney bean, 50g black sesame, 50g seabuckthorn powder, 70g gum arabic, 80g mogroside. The grain flour needs to pass through a 60-mesh sieve. After the raw materials are fully mixed, water is added to adjust the moisture content to 35%.

[0052] Low-temperature extrusion: the temperatures of the five temperature-control sections of the twin-screw extruder used in the present invention are respectively set to 25°C, 30°C, 35°C, 45°C, and 55°C; the feeding speed is 7kg / h, and the screw speed 100r / min.

[0053] Cutting and forming: The material extruded at low temperature passes through a special three-hole grinding head, the length of the extruded material is 7mm, and the cutter is adjusted to make the extruded material thickness 2mm. Dry in an oven at 45°C for 48 hours, then cool and package.

[0054] The resulting product is in the form of figure 1 As shown, with the origi...

Embodiment 2

[0056] Mixed powder formula: 550g highland barley powder, 100g quinoa powder, 50g kidney beans, 50g black rice flour, 50g black sesame, 50g sea buckthorn powder, 80g mogroside, 70g gum arabic. The grain flour needs to pass through a 60-mesh sieve. After the raw materials are fully mixed, water is added to adjust the moisture content to 40%.

[0057] Low temperature extrusion: The temperatures of the five temperature control sections of the twin-screw extruder used in the present invention are respectively set to 25°C, 35°C, 45°C, 55°C, and 65°C; the feeding speed is 7kg / h, and the screw speed is 100r / min.

[0058] Cutting and forming: The material extruded at low temperature passes through a special three-hole grinding head, the length of the extruded material is 7mm, and the cutter is adjusted to make the extruded material thickness 2mm. Dry in an oven at 55°C for 48 hours, then cool and package.

[0059] The index of the obtained product is: the gelatinization degree of th...

Embodiment 3

[0060] Example 3: Effects of Different Moisture Contents on the Textural Properties of the Recombined Highland Barley Grain After Material Extrusion

[0061] Mixing, low-temperature extrusion and cutting are carried out according to the method of Example 1. The difference is that after the raw materials are fully mixed, water is added to adjust the moisture content to 25%, 30%, 40%, 45%, and 50%.

[0062] Table 1 Texture characteristics of highland barley grains after extrusion of materials with different moisture contents

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com