Highland barley and Chinese wolfberry biscuit and processing technology thereof

A wolfberry biscuit and processing technology, which is applied in the field of highland barley processing and highland barley wolfberry biscuit processing technology, can solve the problems of poor appearance and quality, rough taste, and high hardness of biscuits, so as to broaden the scope of development and utilization, increase crispness and The effect of flavor and rich nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

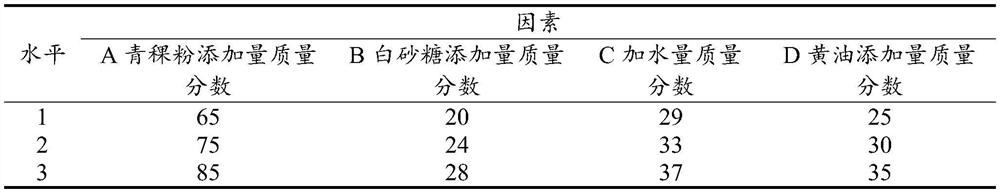

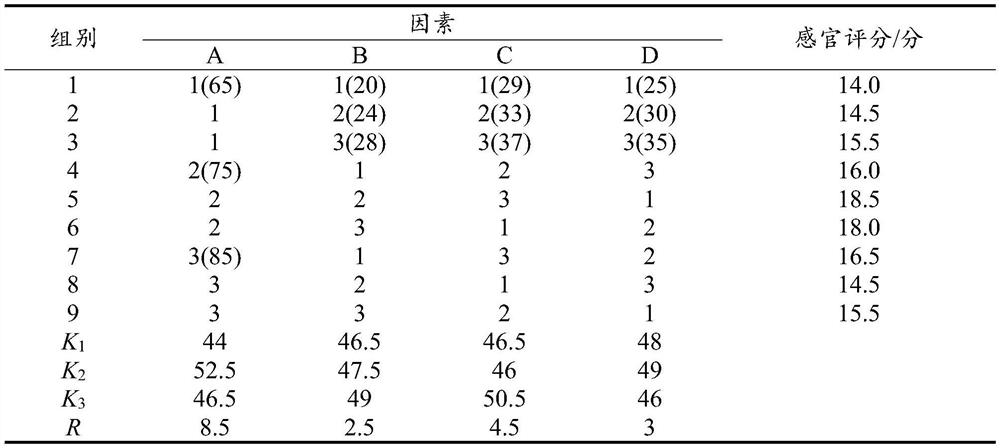

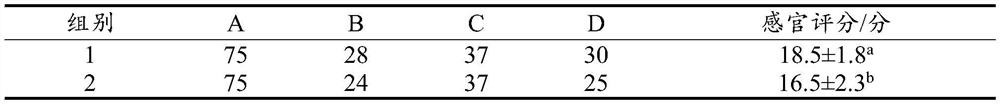

Method used

Image

Examples

Embodiment 1

[0033] 1) Highland barley: buy qualified highland barley raw grains, and remove small clods, stones, metals and other objects in the highland barley;

[0034] 2) Cleaning: the cleaned highland barley surface is further washed with water, the impurities and pesticide residues on the highland barley surface are cleaned to the maximum extent, and an appropriate amount of water is added to enter the next process;

[0035] 3) Moisturizing the wheat: The surface of the highland barley after adding water has high water content, but the internal water content of the grain is low. After the grain moistening treatment, the water is more evenly distributed in the highland barley grain, which brings great convenience and stability to the treatment of the subsequent process. Improve the quality; and design the grain moistening time to be 24h, which can be adjusted according to different climatic requirements;

[0036] 4) Stir-frying: the highland barley after the grain-running treatment is...

Embodiment 2

[0046] 1) Highland barley: buy qualified highland barley raw grains, and remove small clods, stones, metals and other objects in the highland barley;

[0047] 2) Cleaning: the cleaned highland barley surface is further washed with water, the impurities and pesticide residues on the highland barley surface are cleaned to the maximum extent, and an appropriate amount of water is added to enter the next process;

[0048] 3) Moisturizing the wheat: The surface of the highland barley after adding water has high water content, but the internal water content of the grain is low. After the grain moistening treatment, the water is more evenly distributed in the highland barley grain, which brings great convenience and stability to the treatment of the subsequent process. Improve quality; the design time for grain moistening is 36h, which can be adjusted according to different climatic requirements.

[0049]4) Stir-frying: the highland barley after the grain-running treatment is put int...

Embodiment 3

[0059] 1) Highland barley: buy qualified highland barley raw grains, and remove small clods, stones, metals and other objects in the highland barley;

[0060] 2) Cleaning: the cleaned highland barley surface is further washed with water, the impurities and pesticide residues on the highland barley surface are cleaned to the maximum extent, and an appropriate amount of water is added to enter the next process;

[0061] 3) Moisturizing the wheat: The surface of the highland barley after adding water has high water content, but the internal water content of the grain is low. After the grain moistening treatment, the water is more evenly distributed in the highland barley grain, which brings great convenience and stability to the treatment of the subsequent process. Improve the quality; the design time for grain moistening is 48h, which can be adjusted according to different climatic requirements;

[0062] 4) Stir-frying: the highland barley after the grain-running treatment is pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com