Method for improving edible quality of germinated wheat

A technology of germinated wheat and wheat, applied in food drying, food science, etc., can solve problems such as waste of wheat, deterioration of processing quality, loss of nutritional components of staple foods, etc., to prevent deterioration, slow down the hydrolysis process, and improve rough taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Pretreatment of wheat grains, the method is as follows:

[0030] Soak the wheat grains with 1% sodium hypochlorite aqueous solution for 10 minutes, disinfect, then wash with water 3 times until the pH is neutral, soak the sterilized wheat grains in 25°C water for 6 hours, the ratio of wheat grains to water is 1:5 (w / v), to provide the moisture needed for wheat germination and promote wheat germination.

Embodiment 2

[0032] The preparation of germinated wheat, the method is as follows:

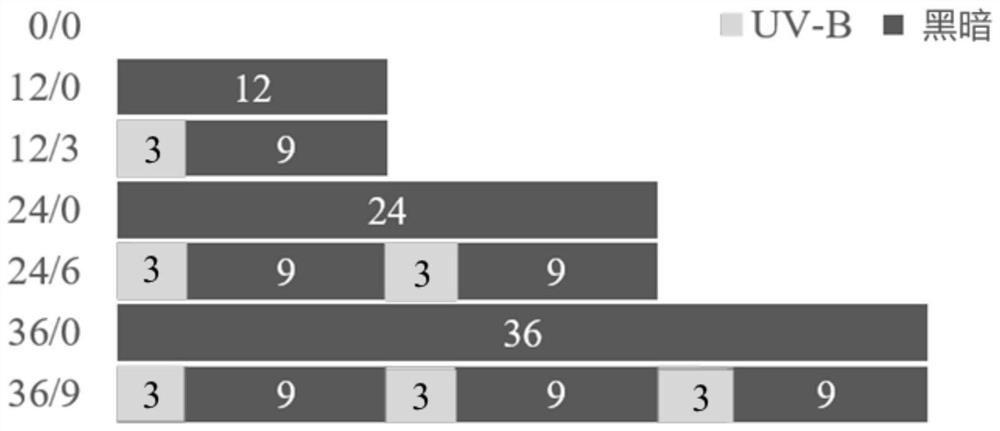

[0033] The pre-treated wheat grains were divided into 7 groups, spread on trays respectively, and germinated in a constant temperature and humidity chamber with a temperature of 30°C and a relative humidity of 80%. The germination conditions of the 7 groups of wheat grains are as follows: "0 / 0" group: germination 0h, UV-B irradiation 0h; "12 / 0" group: germination 12h, UV-B irradiation 0h; "12 / 3" group: Germination 12h, UV-B irradiation 3h; "24 / 0" group: germination 24h, UV-B irradiation 0h; "24 / 6" group: germination 24h, UV-B irradiation 6h; "36 / 0" group : germination 36h, UV-B irradiation 0h; "36 / 9" group: germination 36h, UV-B irradiation 9h. Among them, UV-B irradiation is carried out simultaneously with wheat grain germination. Every 12 hours of wheat grain germination, UV-B irradiation is carried out synchronously, and the UV-B irradiation time is 3 hours, such as figure 1 shown. In this embodimen...

Embodiment 3

[0035] The preparation of wheat flour, the method is as follows:

[0036] Each group of germinated wheat grains in Example 2 was further divided into two groups. One group was subjected to continuous drying treatment: the germinated wheat grains were placed in a hot air drying oven for continuous drying at a drying temperature of 45°C until the moisture content was 14%. Another group was subjected to intermittent drying treatment: the germinated wheat grains were dried at 45°C until the moisture content was 30%, and then at 80°C until the moisture content was 14%. Grind the above dried germinated wheat respectively by Buhler test mill to obtain 8 layers of wheat flour: coarse bran, fine bran, 1M, 2M, 3M, 1B, 2B and 3B; among them, coarse bran, fine bran 1M, 2M, and 3M are heart-milled flour, and 1B, 2B, and 3B are bran-milled flour.

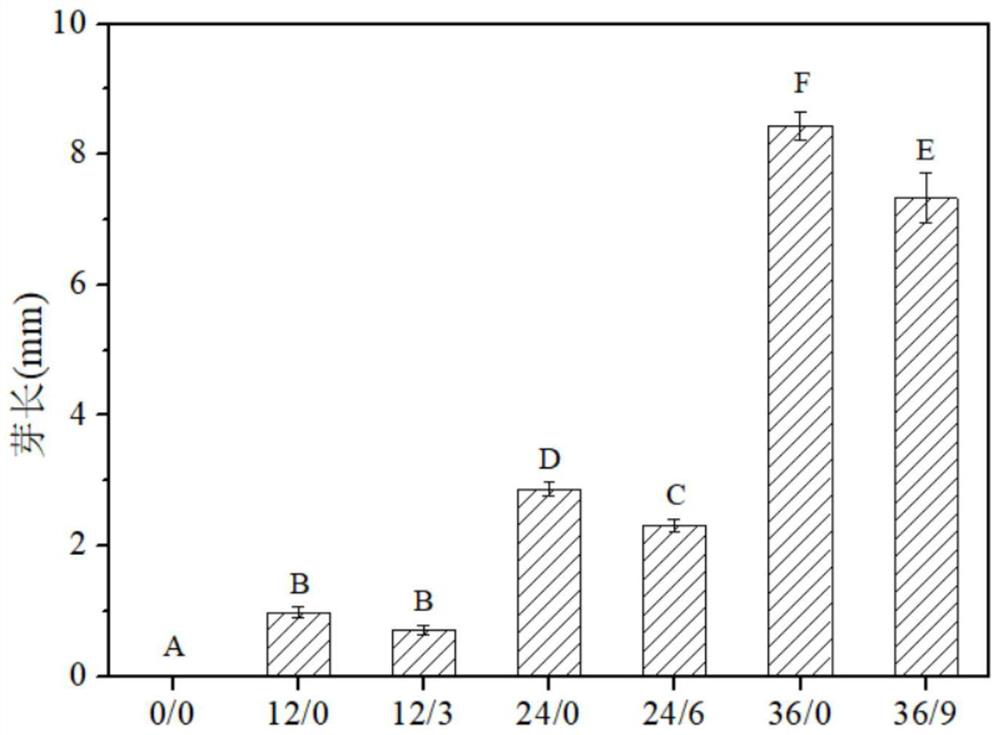

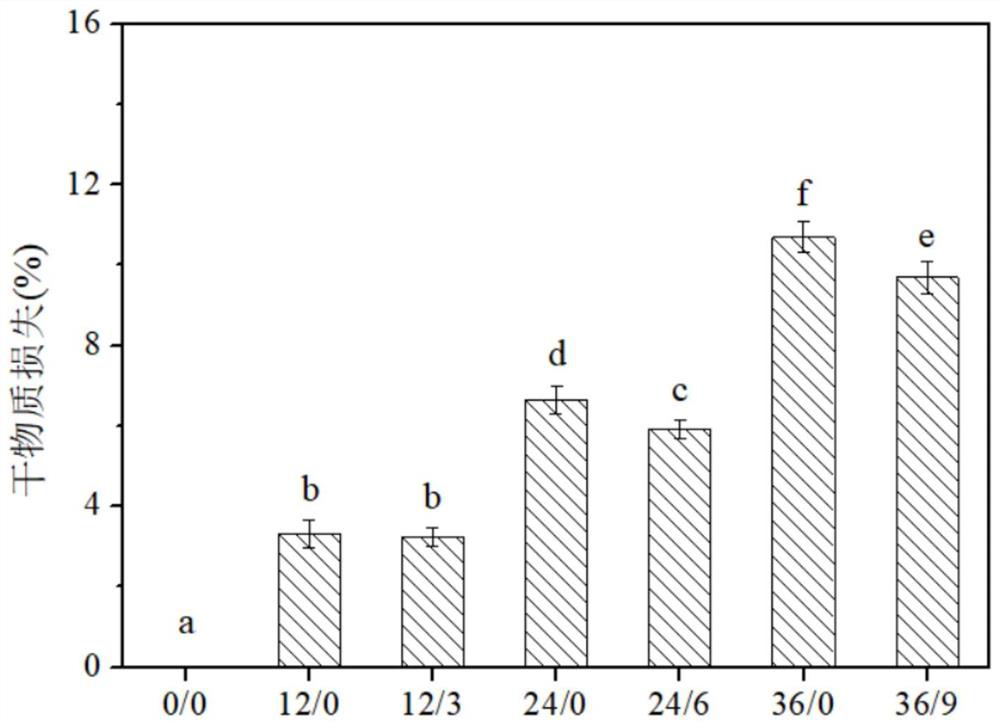

[0037] Effects of UV-B Radiation Stress on Germination Length of Germinated Wheat

[0038] The sprout length of each group of germinated whea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com