Horizontal and vertical switching rolling mill for bar finish rolling

A technology of horizontal rolling mill and vertical rolling mill, which is applied to the driving device of metal rolling mill, metal rolling stand, metal rolling mill stand, etc., which can solve the problems of large vibration of rolling mill, increased resistance, deformation of stand, etc., to achieve Guaranteed dimensional accuracy, improved production efficiency, and stable high-speed operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

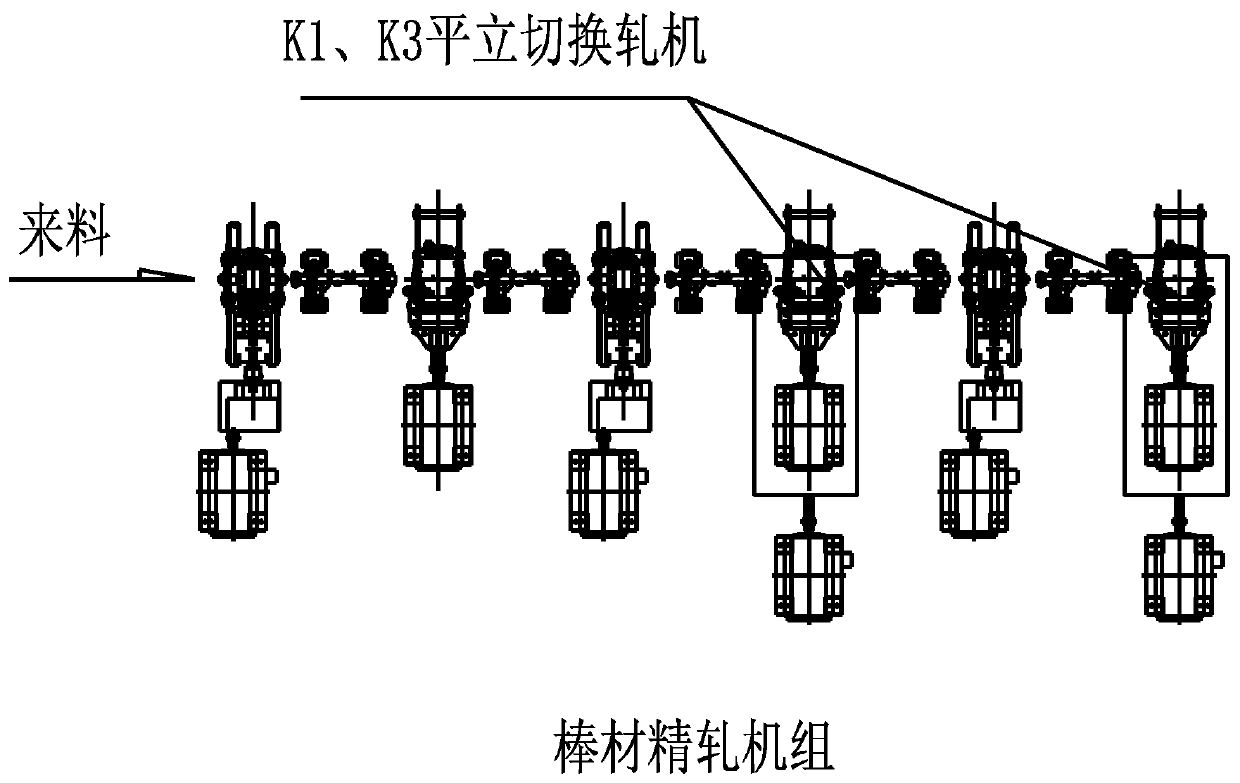

[0019] The invention provides a horizontal-vertical switch rolling mill for bar finish rolling.

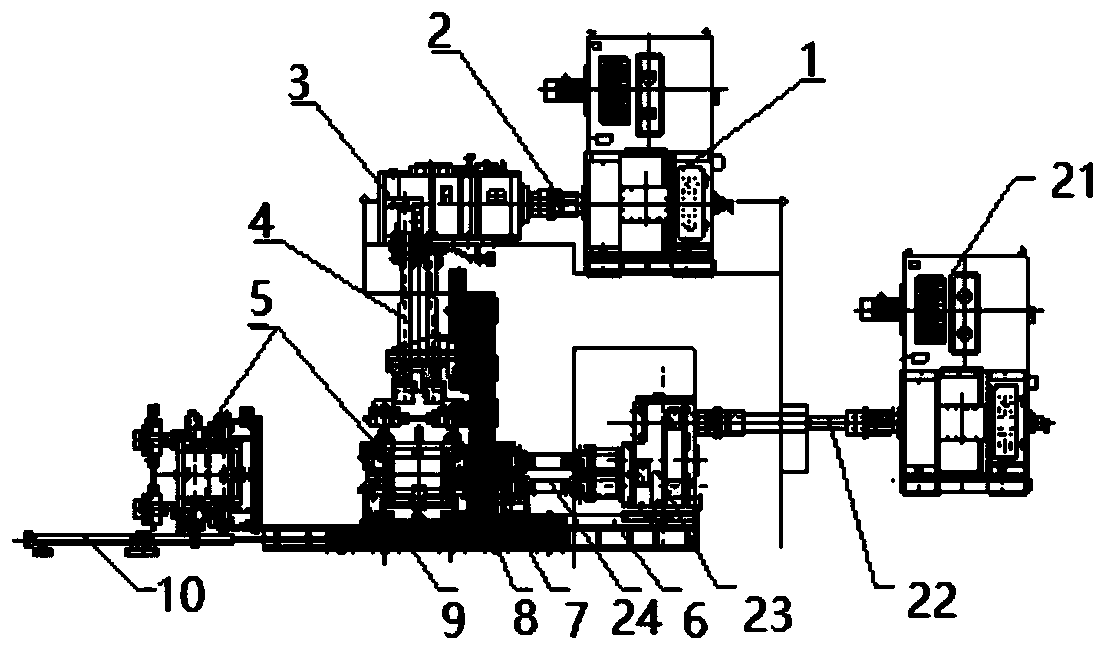

[0020] like figure 1 As shown, the rolling mill includes main motor one 1, main motor two 21, coupling one 2, coupling two 22, gearbox one 3, gearbox two 23, universal joint shaft one 4, universal joint shaft two 24. Rolling mill body 5, gearbox moving base 6, horizontal static base 7, pin hydraulic cylinder 8, vertical rolling mill roll changing trolley 9, and traverse hydraulic cylinder 10, of which, main motor 1, coupling 2, gear box One 3 and the universal joint shaft one 4 constitute a vertical rolling mill system, which is installed on the concrete platform foundation, and the vertical rolling mill system is connected to the rolling mill body 5 throug...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap