General type industrial robot additional shaft guide rail structure

A technology of industrial robots and additional axes, which is applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of insufficient internal structure protection performance, inconvenient installation and maintenance, and low processing and manufacturing costs, so as to achieve good mechanical protection performance and convenience. The effect of equipment installation and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

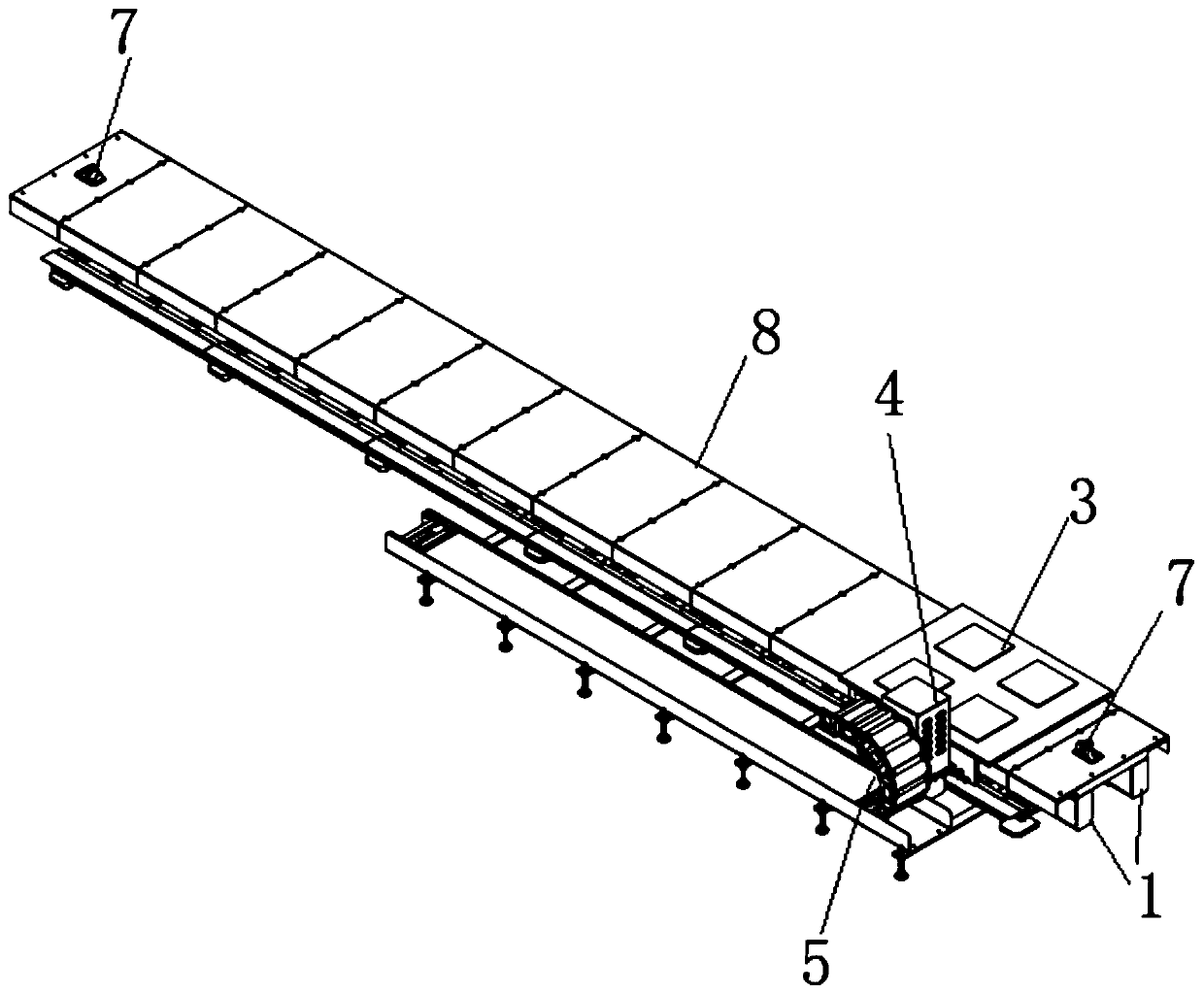

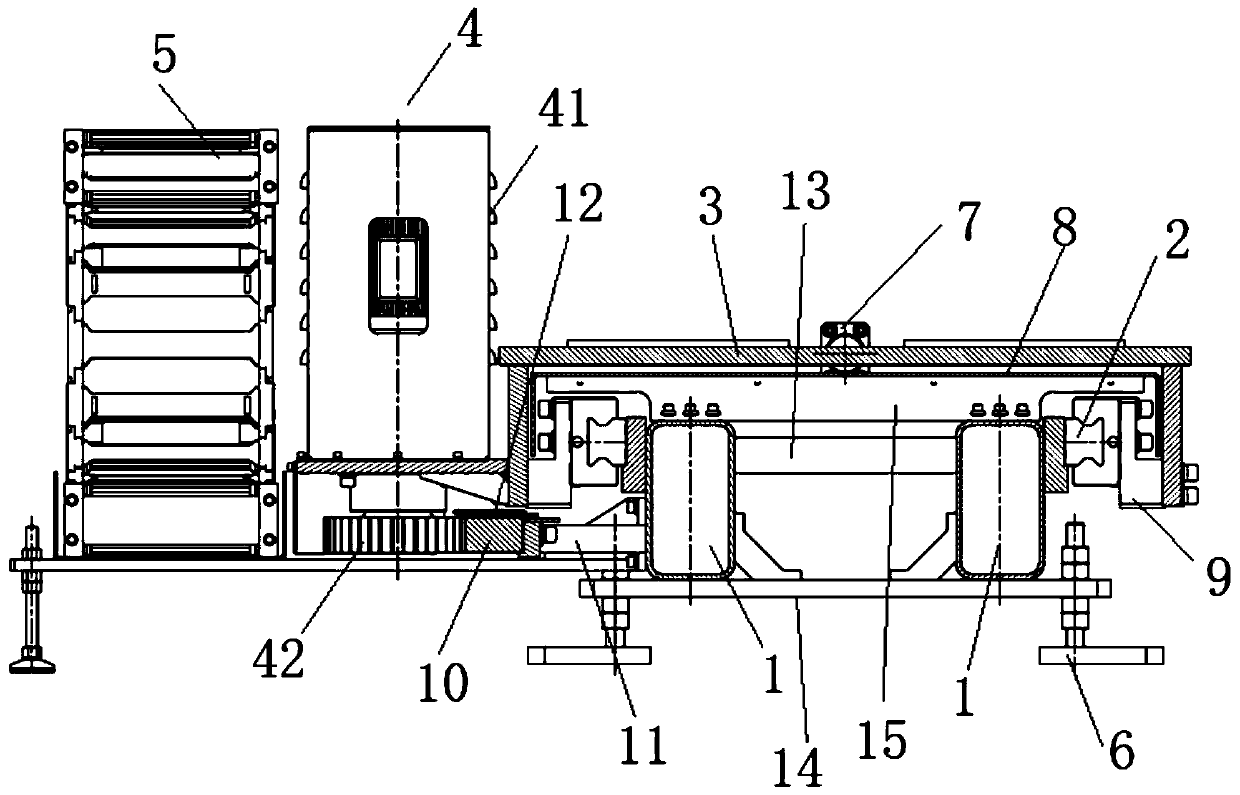

[0028] Such as Figure 1-8 As shown, the general-purpose industrial robot additional shaft guide rail structure of the present invention includes:

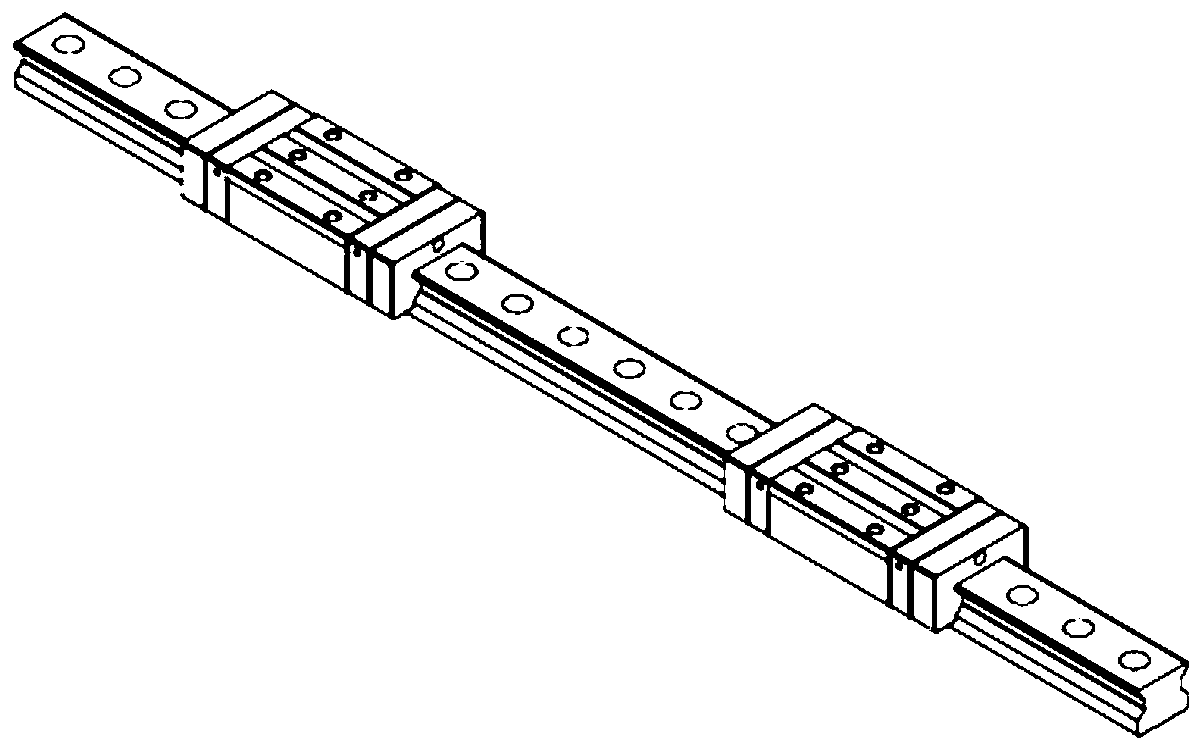

[0029] The linear guide rail 2 symmetrically installed on the axially outer side of the guide rail base frame and the motor drive mechanism 4 arranged on the axial side of the guide rail base frame, the motor drive mechanism includes a servo motor with a protective cover 41 40 is a rack and pinion transmission mechanism that provides power. One side of the rack and pinion transmission mechanism is axially arranged with a drag chain assembly 5; the rack and pinion transmission mechanism is driven by the servo motor and installed on a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com