System and method for treating wastewater containing organic matter by adsorption and preparing carbon nanomaterials

A technology of carbon nanomaterials and organic matter, which is applied in the field of waste water and the system of preparing carbon nanomaterials, can solve the problems of high cost, difficult separation, no sales value, etc., and achieve the effect of saving consumption and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

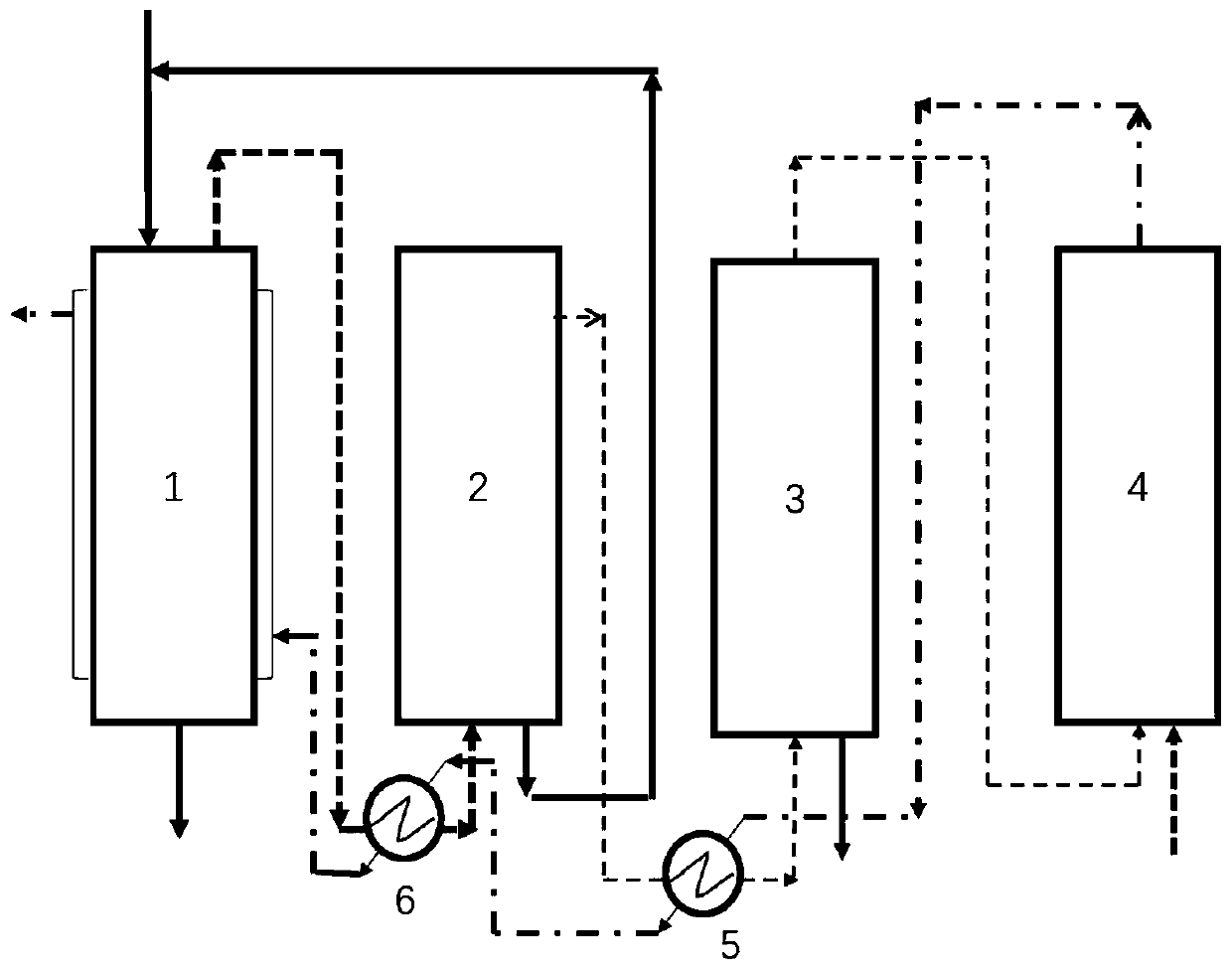

[0032] Such as figure 1 As shown, the jacketed wastewater adsorption / desorption device 1, the concentrated waste liquid separation device 2 (rectification tower), the carbon nanomaterial production device 3 and the tail gas oxidation device 4 are connected in sequence, and the tail gas oxidation device 4 produces The flue gas is connected with the carbon nanomaterial production device 3 through the first heat exchanger 5 through the pipeline, and then connected with the concentrated waste liquid separation device 2 through the second heat exchanger 6 through the pipeline, and then adsorbed / adsorbed with the jacketed waste water through the pipeline The jacket of the desorption device 1 is connected.

[0033]Fill the carbon adsorbent in the wastewater adsorption / desorption device 1 with a jacket, and the wastewater containing organic matter (500ppm, chlorododecane, No. 0 diesel oil, picoline, linoleic acid) is transferred from the wastewater with a jacket The top of the adsorp...

Embodiment 2

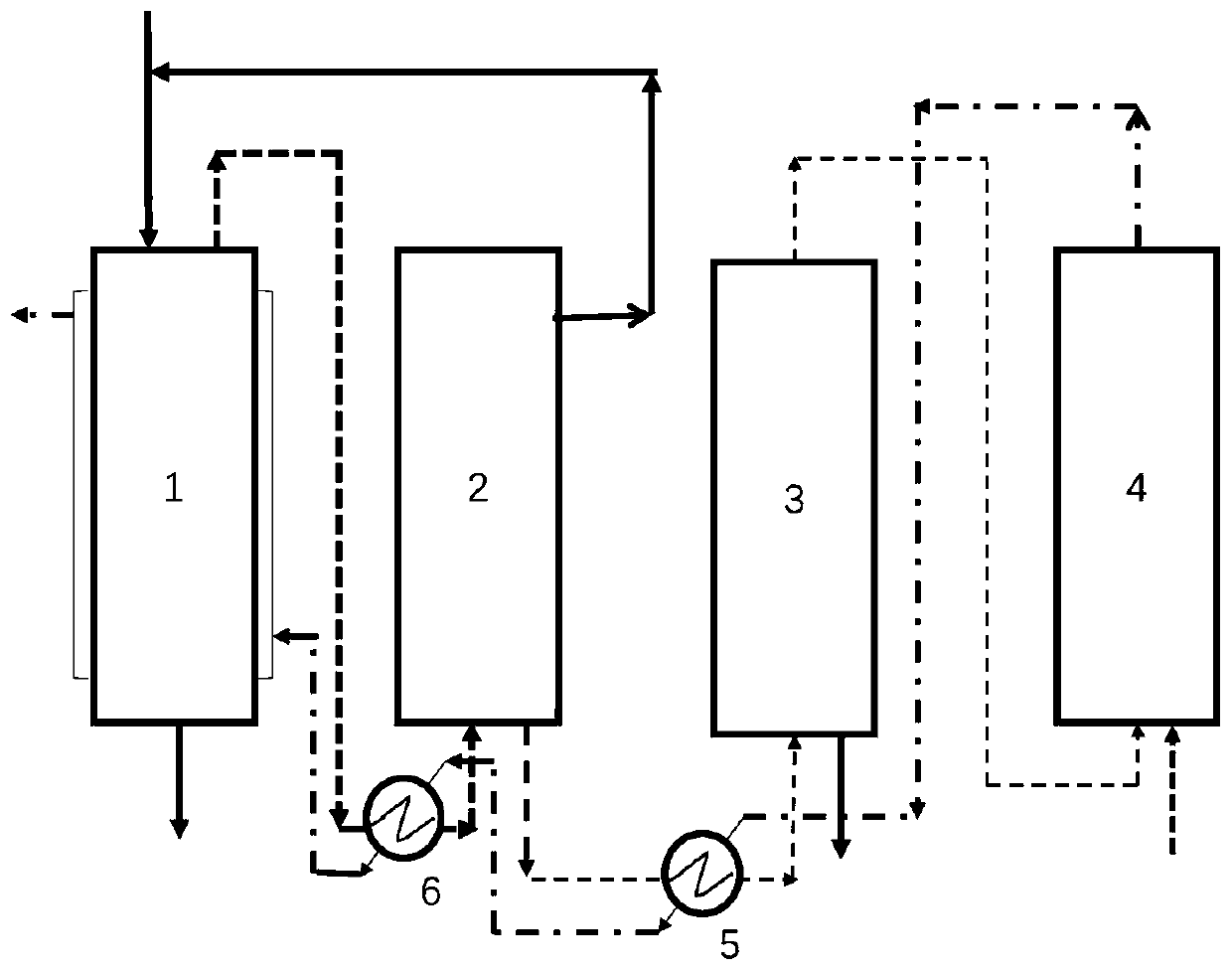

[0039] Such as figure 2 As shown, the jacketed wastewater adsorption / desorption device 1, the concentrated waste liquid separation device 2 (rectification tower), the carbon nanomaterial production device 3 and the tail gas oxidation device 4 are connected in sequence, and the tail gas oxidation device 4 produces The flue gas is connected with the carbon nanomaterial production device 3 through the first heat exchanger 5 through the pipeline, and then connected with the concentrated waste liquid separation device 2 through the second heat exchanger 6 through the pipeline, and then adsorbed / adsorbed with the jacketed waste water through the pipeline The jacket of the desorption device 1 is connected.

[0040] Fill the carbon adsorbent in the jacketed waste water adsorption / desorption device 1 . Wastewater containing organic matter (20000ppm, epichlorohydrin, amantadine, o-nitrophenol, phthalic acid, mixture of any ratio of N-methylpyrrolidone) from the jacketed wastewater ads...

Embodiment 3

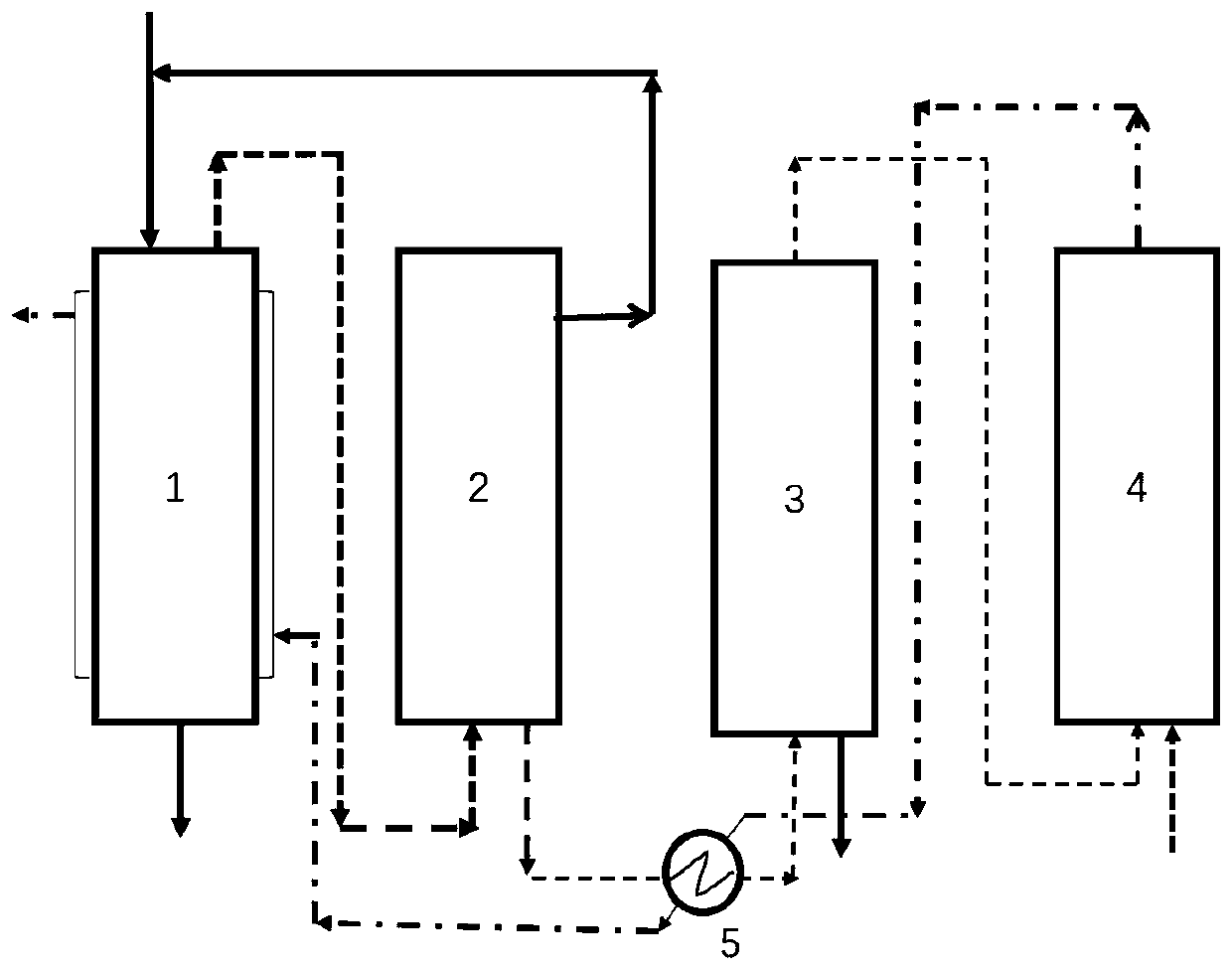

[0046] Such as image 3 As shown, the jacketed wastewater adsorption / desorption device 1, the concentrated waste liquid separation device 2 (rectification tower), the carbon nanomaterial production device 3 and the tail gas oxidation device 4 are connected in sequence, and the tail gas oxidation device 4 produces The flue gas is connected to the carbon nanomaterial production device 3 through the first heat exchanger 5 through the pipe, and then connected to the jacket of the jacketed wastewater adsorption / desorption device 1 through the pipe.

[0047] Fill the carbon adsorbent in the jacketed wastewater adsorption / desorption device 1 with a porosity of 50%. The wastewater containing organic matter (10000ppm, dichloroacetophenone, benzothiophene, β-alanine in any proportion mixture) is introduced from the top of the jacketed wastewater adsorption / desorption device 1, and the adsorption temperature is 50°C , after passing through the adsorbent layer inside, the organic matter ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com