Graphene-like self-dispersing paint and preparation method thereof

A graphene, self-dispersing technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problem of insufficient comprehensive performance of the coating system, achieve increased convenience and stability, good anti-corrosion effect, and broaden the selection of materials range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step a: Mix 10 parts of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde and 11 parts of p-phenylenediamine, ball mill for 2 hours (ball-material ratio 10 / 1), wash with acetone and dry to obtain Graphene-like fillers;

[0035] Step b: Take 60 parts of epoxy resin, 6 parts of graphene-like filler, and 10 parts of diluent, mix and stir evenly, and let stand for 2 days to obtain a mixed slurry;

[0036] Step c: adding 30 parts of curing agent to the mixed slurry, stirring evenly, and vacuum degassing to obtain a self-dispersing graphene-like anticorrosion coating;

[0037] Step d: apply the paint on the metal, and cure it at room temperature for 24 hours, and then cure it at 60° C. for 24 hours to obtain an anti-corrosion coating.

Embodiment 2

[0039] Step a: Mix 11 parts of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde and 14 parts of 2-methyl-p-phenylenediamine, ball mill for 2 hours (ball-material ratio 10 / 1), and wash with acetone Post-drying to obtain graphene-like fillers;

[0040] Step b: Take 60 parts of epoxy resin, 8 parts of graphene-like filler, and 9 parts of diluent, mix and stir evenly, and let stand for 2 days to obtain a mixed slurry;

[0041] Step c: adding 30 parts of curing agent to the mixed slurry, stirring evenly, and vacuum degassing to obtain a self-dispersing graphene-like anticorrosion coating;

[0042] Step d: apply the paint on the metal, and cure it at room temperature for 24 hours, and then cure it at 60° C. for 24 hours to obtain an anti-corrosion coating.

Embodiment 3

[0044] Step a: Mix 11 parts of 2,4,6-trihydroxy-1,3,5-benzenetricarbaldehyde and 15 parts of 2-ethyl-p-phenylenediamine, ball mill for 2 hours (ball-to-material ratio 10 / 1), and wash with acetone Post-drying to obtain graphene-like fillers;

[0045] Step b: Take 70 parts of epoxy resin, 5 parts of graphene-like filler, and 7 parts of diluent, mix and stir evenly, and let stand for 2 days to obtain a mixed slurry;

[0046] Step c: adding 50 parts of curing agent to the mixed slurry, stirring evenly, and vacuum degassing to obtain a self-dispersing graphene-like anti-corrosion coating;

[0047] Step d: apply the paint on the metal, and cure it at room temperature for 24 hours, and then cure it at 60° C. for 24 hours to obtain an anti-corrosion coating.

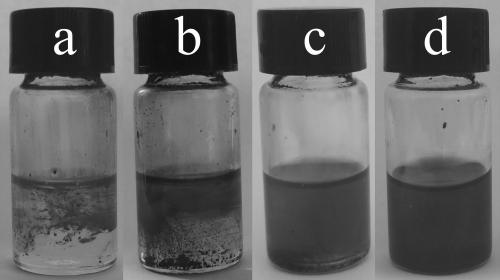

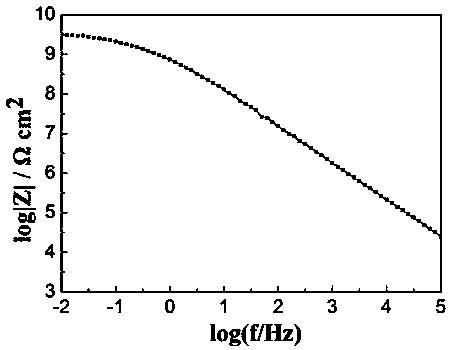

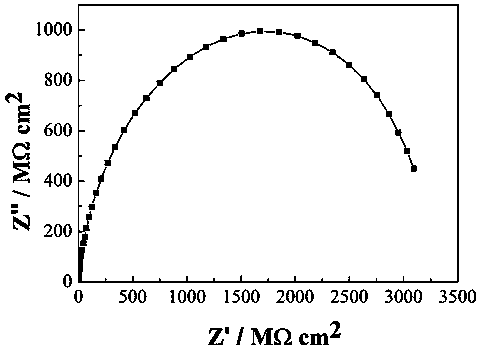

[0048] The self-dispersing graphene-like anti-corrosion coating prepared by the present invention does not require any additional dispersing aids, and the slurry can obtain a mixed system with good stability and dispersibility ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com