Method and device for real-time thickness measurement and feedback of laser cladding

A laser cladding and thickness measurement technology, applied in measuring devices, metal material coating processes, instruments, etc., can solve the problems of difficult manual measurement, high cost of CCD cameras, inability to measure, etc., to improve cladding efficiency and processing. The effect of improving the qualified rate of finished products, improving the qualified rate of processed finished products, and reducing manual measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments.

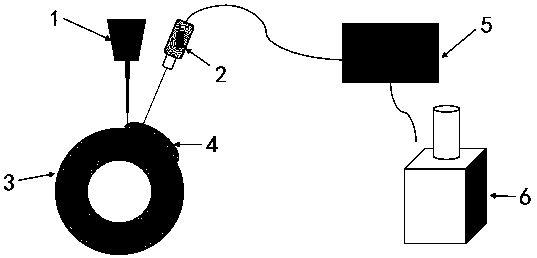

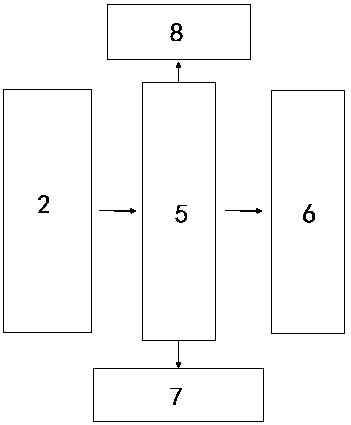

[0033] as attached figure 1 As shown, the device of the present invention includes a laser displacement sensor 2 and a controller 5. The laser displacement sensor 2 is installed near the laser processing head 1 and moves with it. The laser displacement sensor 2 measures that the laser is perpendicular to the laser cladding layer 4, which is Ensure that the measurement position is the low point of the laser cladding layer 4, and the measurement point is set on the same arc as the molten pool and close to the overlap of the two laser cladding layers 4.

[0034] Laser displacement sensor 2 is a diffuse reflection type digital display laser displacement sensor. Its main function is to measure height. Based on the principle of triangulation, it can radiate a laser line segment to the object, and receive diffuse reflection projection through the CMOS photosensitive element to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com