Manufacturing technology of PET film used for liquid crystal writing board

A preparation process and writing board technology, which is applied in optics, instruments, nonlinear optics, etc., can solve the problems that the film will reflect light, affect writing and wiping, and affect the display effect, etc., and achieve anti-skid and wear-resistant effects, anti-glare The texture is evenly distributed and the effect of improving the writing feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

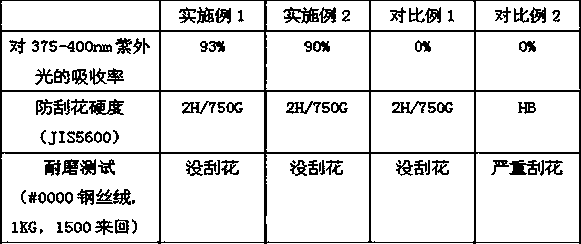

Embodiment 1

[0023] Embodiment 1: PET film for liquid crystal tablet.

[0024] The steps of the PET film preparation process include:

[0025] a. Configure the coating liquid: mix 97% acrylic monomer, 2% ultraviolet absorber, and 1% ultraviolet trigger curing agent according to the weight ratio. The ultraviolet absorber is 2-hydroxy-4-n-octyloxybenzophenone.

[0026] b. Coating: Coating is carried out with a slit-type coating head or a scraper-type coating head, and the ultraviolet absorbing coating liquid is evenly coated on the upper surface of the PET base film to obtain a coating layer. Wherein the coating layer thickness is 0.006mm.

[0027] c. Press anti-glare texture: use anti-glare texture roller and light roller to squeeze the upper and lower sides of PET base film, so that the surface of the coating layer is pressed with anti-glare texture. The surface of the anti-glare textured roller is provided with a frosted texture, the frosted texture is composed of a plurality of partic...

Embodiment 2

[0030] Embodiment 2: PET film for liquid crystal tablet.

[0031] The steps of the PET film preparation process include:

[0032] a. Configure the coating liquid: mix 98% acrylic monomer, 1% ultraviolet absorber, and 1% ultraviolet trigger curing agent according to the weight ratio. The ultraviolet absorber is 2-hydroxy-4-n-octyloxybenzophenone. Steps b-d are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com