A new type of roller processing method in solar cell texturing equipment

A technology of solar cells and processing methods, applied in the direction of sustainable manufacturing/processing, circuits, electrical components, etc., can solve the problems of reducing the proportion of low-failure cells, and achieve the effect of improving the efficiency of texturing

Active Publication Date: 2021-04-06

江苏华恒新能源有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the various characteristics of graphene itself, it can not only improve the effect of the suede surface of the silicon wafer and increase the output; but also can well avoid the deposition of silver on the surface of the roller, which solves the problem of the distribution of silver in the later stage of the chain black silicon liquid. Improve the service life of the chemical solution, improve the efficiency of black silicon cells and reduce the proportion of low-failure cells

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] In order to deepen the understanding of the present invention, this embodiment will be described in detail below in conjunction with specific implementation modes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

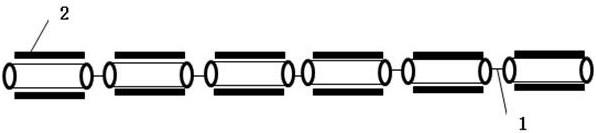

The invention relates to a novel roller processing method in solar cell texturing equipment. The method includes the following steps: 1) preparing graphene; 2) transfer of graphene; the scheme improves the texturing output of silicon wafers and the uniformity of the textured surface To solve the problem that the adsorption of silver on the rollers in chain-type black silicon texturing equipment affects the life of the liquid medicine and the efficiency of cells, and provides a new type of roller used in solar cell texturing equipment.

Description

technical field [0001] The invention relates to a processing method, in particular to a novel roller processing method in solar cell texturing equipment, and belongs to the technical field of crystalline silicon solar cell processing. Background technique [0002] The chemical properties of graphene are similar to graphite, and graphene can adsorb and desorb various atoms and molecules. When these atoms or molecules are used as donors or acceptors, the concentration of graphene carriers can be changed, while graphene itself can maintain good conductivity. But when adsorbing other substances, such as H + and OH - When , some derivatives will be produced, which will make the conductivity of graphene worse, but no new compounds will be produced. The structure of graphene is very stable, and the carbon-carbon bond is only 1.42. The connection between carbon atoms inside graphene is very flexible. When an external force is applied to graphene, the surface of the carbon atoms ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L31/18H01L31/0236

CPCH01L31/02363H01L31/1804Y02E10/547Y02P70/50

Inventor 吴卫伟王欣皇韶峰

Owner 江苏华恒新能源有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com