Mechanical processing method of wire arranging hole of large-size mold cavity board

A wiring hole and cavity technology, which is applied in the field of mechanical processing of wiring holes in large-scale combined welding cavity plates, can solve the problems of bottlenecks in production efficiency and process, and that the high-efficiency performance of CNC milling machines cannot be fully utilized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

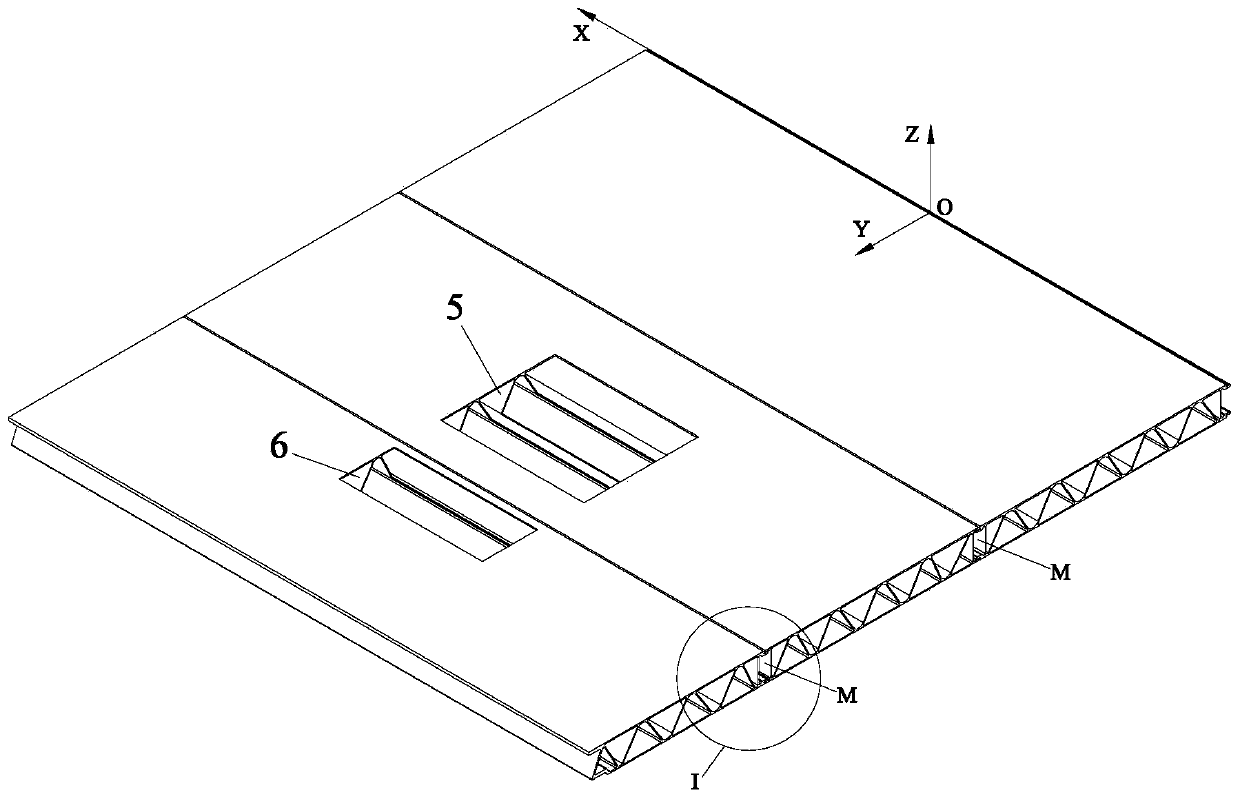

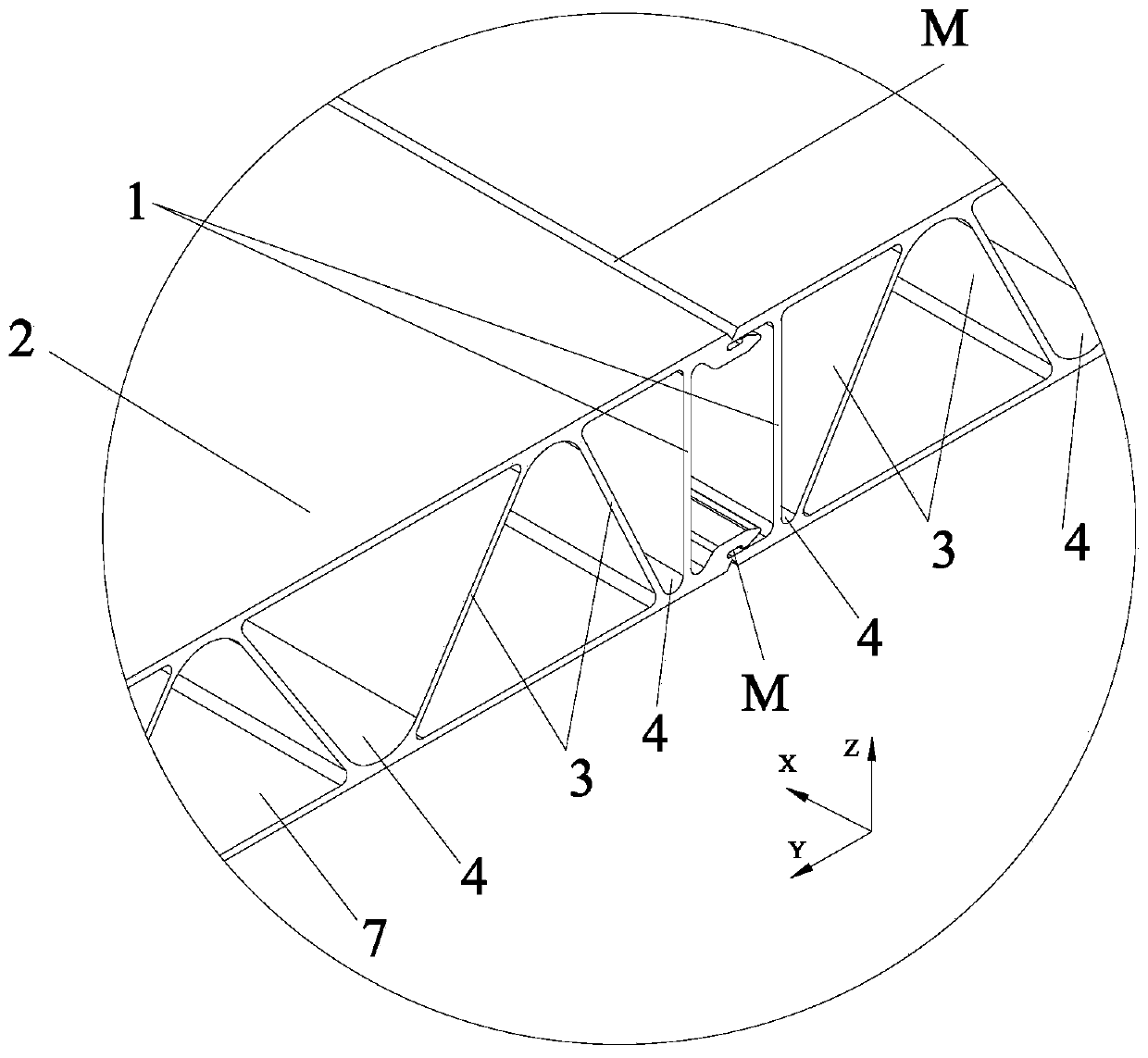

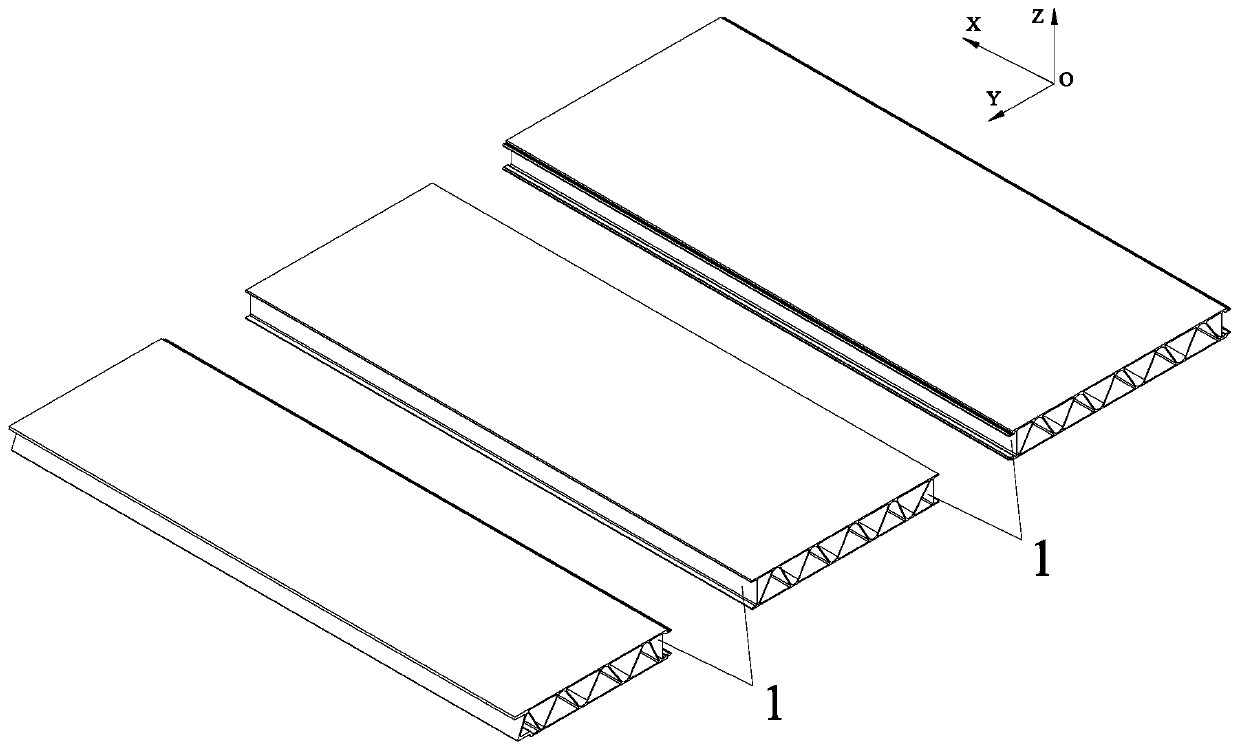

[0078] The present invention will be further described in detail below in conjunction with the drawings.

[0079] Such as Figure 15 to Figure 20 As shown, the wiring hole machining method of the large-sized cavity plate of the present invention includes the following steps:

[0080] Step 1: The control system of the CNC milling machine determines whether the trapezoidal quadrangular prism clearing area of the current wiring hole to be processed is a conventional trapezoidal quadrangular prism or a right-angled trapezoidal quadrangular prism according to the pre-inputted theoretical design parameters of the wiring hole drawing of the large cavity sheet It is: if the Y-direction theoretical coordinate value of the bottom and bottom of the trapezoid of the current wiring hole to be processed is equal to the theoretical Y coordinate value of the bottom and bottom of the trapezoid, or the Y-direction theoretical coordinate value of the bottom and proximal end of the trapezoid of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com