Cutter and tool bit structure thereof

A technology of cutter head and cutting edge, which is applied in the field of cutting tool and its cutter head structure, can solve the problems of difficult tool processing, short life and low processing efficiency, achieve low surface roughness, improve wear resistance, and improve processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

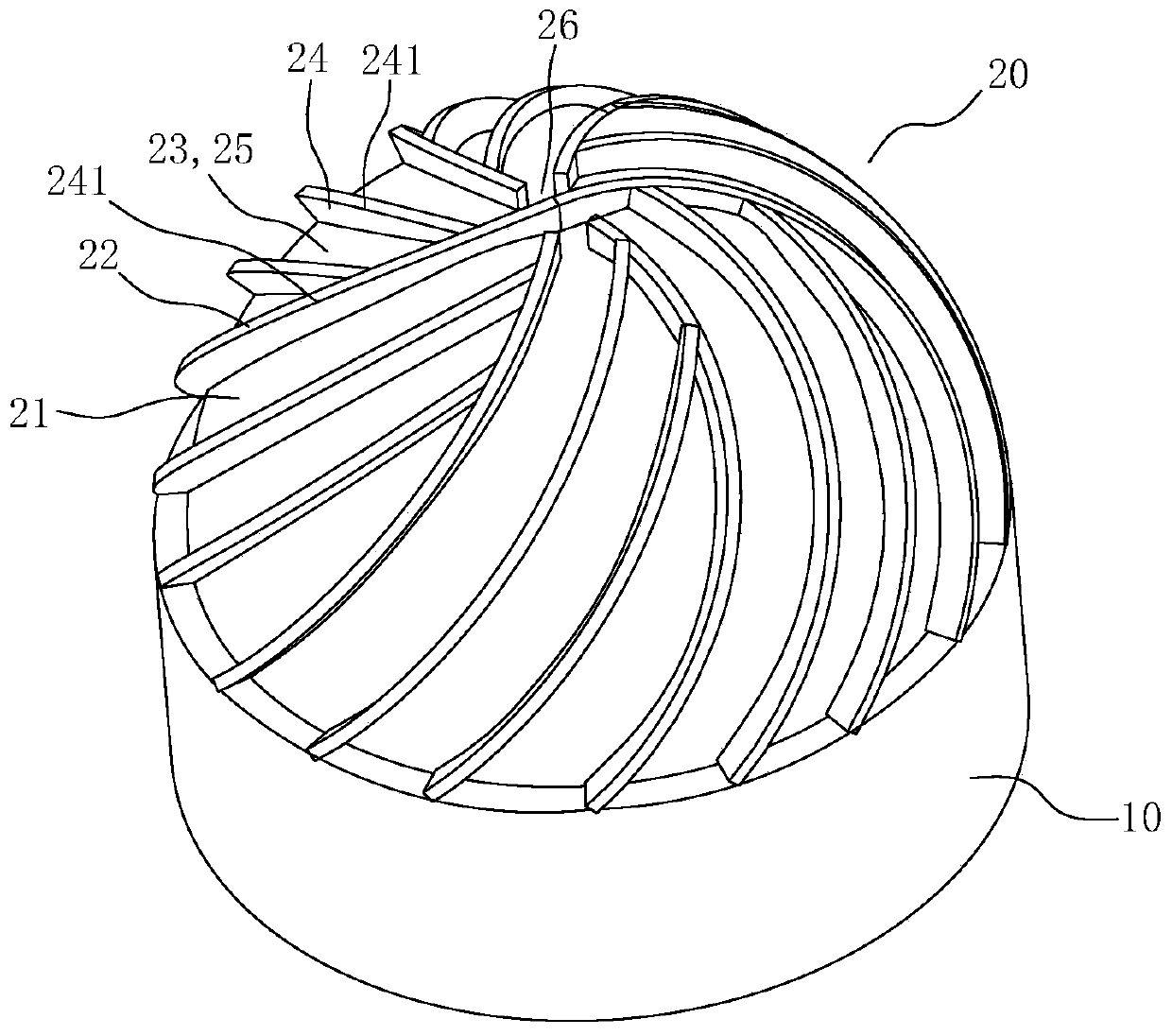

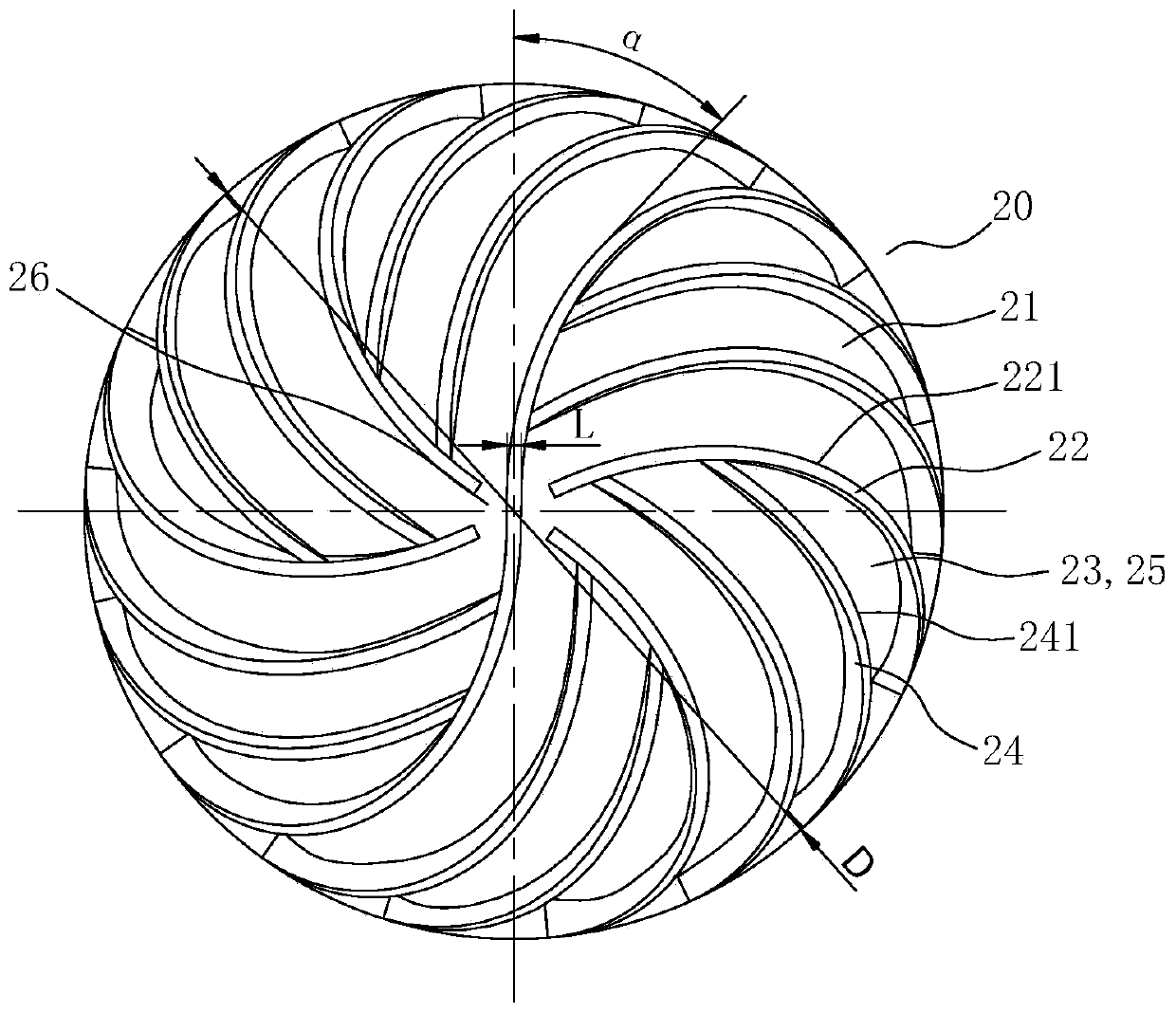

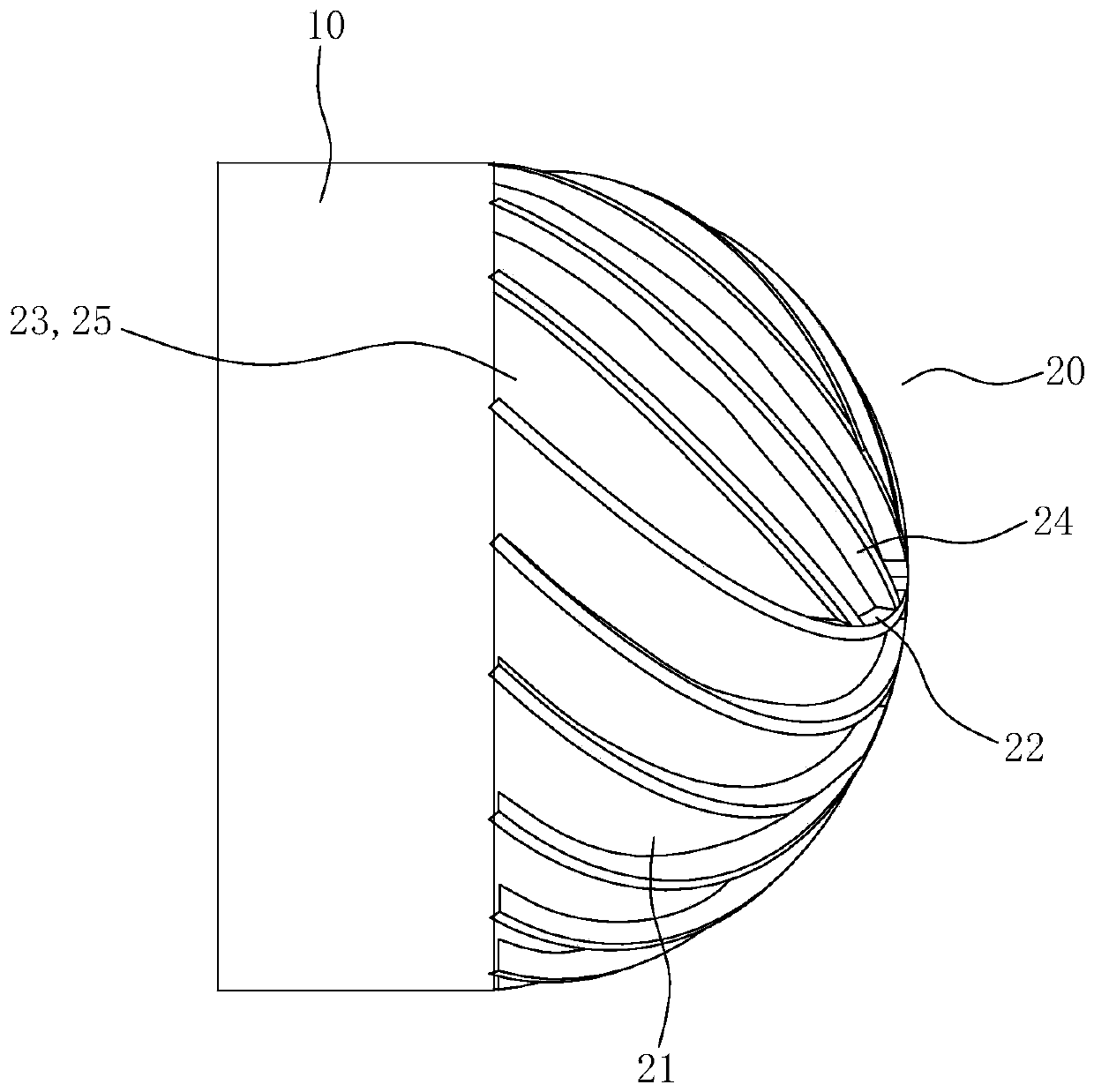

[0040] Such as Figure 1-Figure 3 As shown, the present embodiment provides a cutter head structure for a cutting tool, the cutter head structure includes a connecting portion 10 and a cutting edge portion 20 arranged at the front end of the connecting portion 10, and the cutting edge portion 20 includes a fixed The cutting main body 21 and several first cutting edges 22 at the front end of the connecting part 10, the outer surface of the cutting main body 21 is an outwardly convex arc surface, and the first cutting edge 22 is helical, and the first cutting edge The number of edges of 22 is defined as S, and the diameter of the cutting body 21 is defined as D. The following relationship must be satisfied between S and D: 4D≤S≤15D, that is, the number of edges S of the first cutting edge 22 is the diameter D of the cutting body 21 The diameter D of the cutting body 21 is 0.5-32 mm, and the width L of the first cutting edge 22 is 0.01 mm-0.1 mm.

[0041]The cutter head structur...

Embodiment 2

[0064] Please refer to the attached Figure 4 As shown, this embodiment provides another cutter head structure. The difference between this embodiment and Embodiment 1 is that one end of the first cutting edge 22 is set at the top area of the cutting body 21, and the first The other end of the cutting edge 22 extends to the outer surface of the connecting portion 10; one end of the second cutting edge 24 is connected to the first cutting edge 22, and the other end of the second cutting edge 24 extends to the The outer surface of the connection part 10.

[0065] Compared with the first embodiment, the cutter head structure in this embodiment has a larger processing range.

[0066] For the same purpose, the second aspect of the embodiments of the present invention provides a cutting tool (not shown in the drawings), which includes a tool handle and a tool mounted on the front end of the tool handle as in any embodiment of the first aspect. The cutter head structure, the rear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Blade width | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com