Corn polylactic acid fiber fabric and preparation method thereof

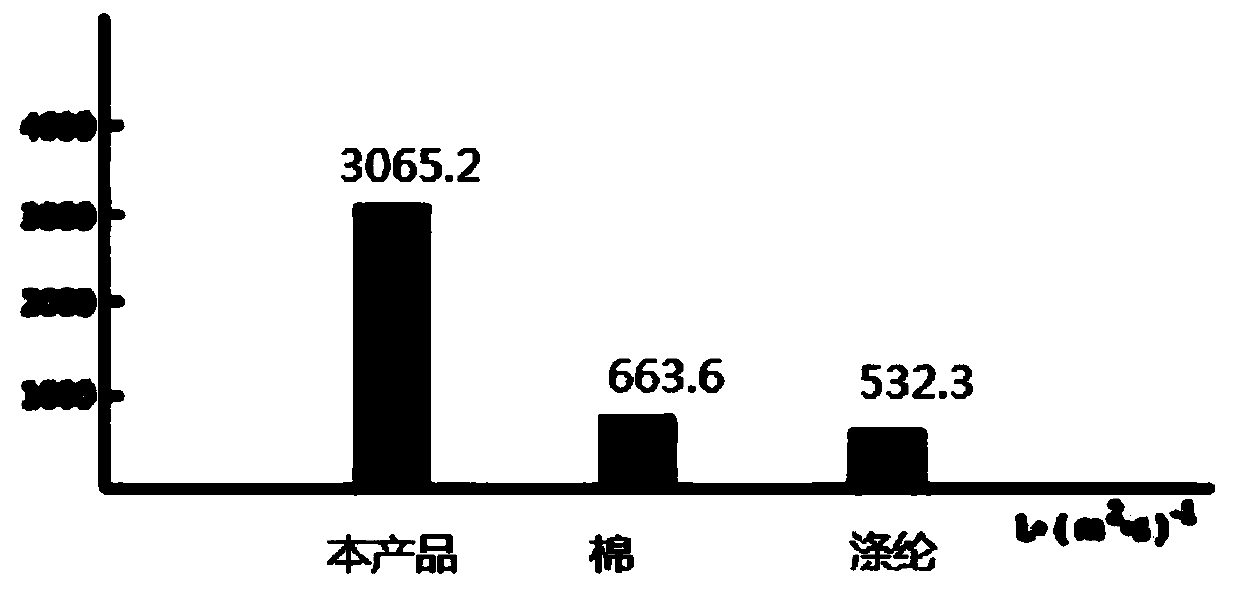

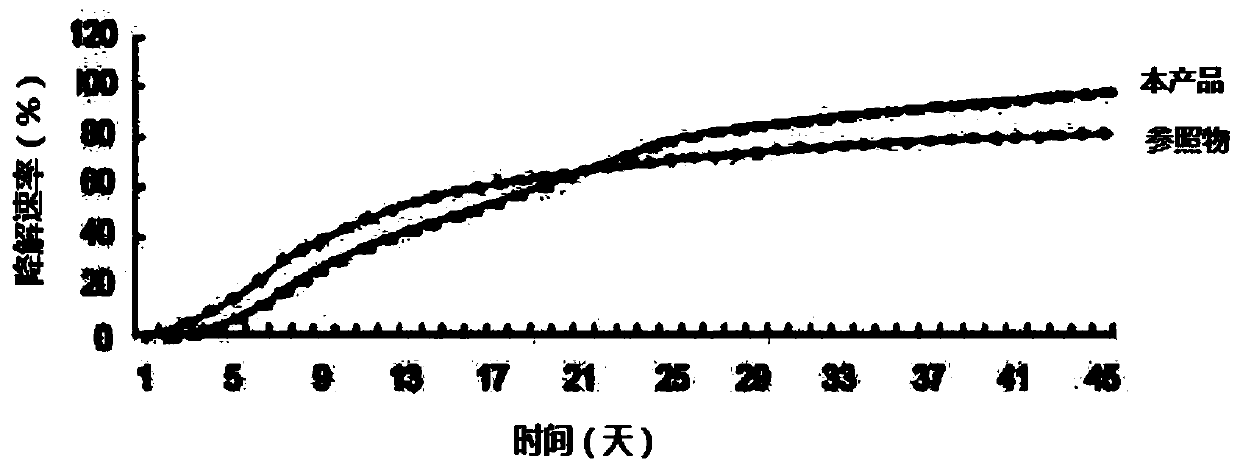

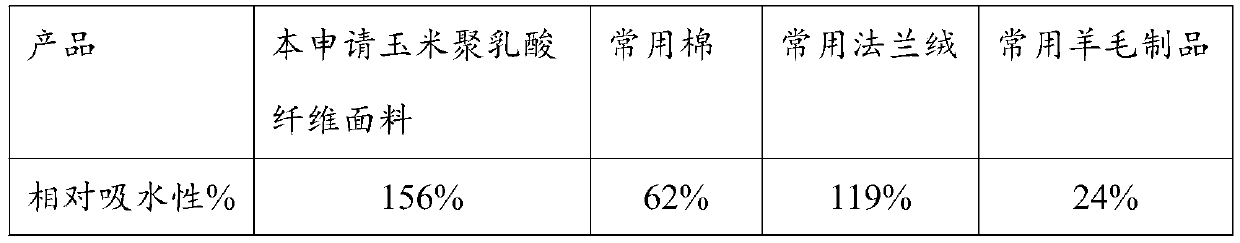

A polylactic acid fiber and corn technology, applied in the field of fabrics, can solve problems such as reverse osmosis, and achieve the effect of good degradability, dryness and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The present invention also provides a preparation method of the corn polylactic acid fiber fabric described in the above technical solution, comprising the following steps:

[0023] Laminate a breathable film on the surface of corn polylactic acid fiber spunlace non-woven fabric to obtain a semi-finished fabric;

[0024] Perforating and drying one side of the semi-finished corn polylactic acid fiber spunlace nonwoven fabric to obtain the corn polylactic acid fiber fabric.

[0025] In the present application, firstly, a breathable film is laminated on one side of the corn polylactic acid fiber spunlace nonwoven fabric; the material of the breathable film is preferably TPEE, and the thickness of the breathable film is preferably 2 to 5 μm, more preferably 2 to 5 μm. 3μm; the lamination temperature is preferably 40-60°C, more preferably 60°C, the pressure is preferably 0.4-0.6Mpa, more preferably 0.4Mpa; a zero-tension film release device is preferred during lamination to ...

Embodiment 1

[0031] The preparation of corn polylactic acid fiber spunlace non-woven fabric: firstly, corn grains are used as raw materials, which are fermented and converted into lactic acid, then polymerized and spun to make corn polylactic acid fibers, and then corn polylactic acid fibers are prepared from corn polylactic acid fibers. Fiber spunlace non-woven fabrics, extraction of corn polylactic acid fibers and preparation of spunlace non-woven fabrics can all be done in any way known to those skilled in the art;

[0032] Preparation of corn polylactic acid fiber fabric: put the corn polylactic acid fiber spunlace non-woven fabric prepared above and 2 μm thick TPEE breathable film on the self-made equipment, turn on the equipment, and laminate the TPEE breathable film to the corn polylactic acid fiber water The surface of the non-woven fabric is punctured, the lamination temperature is 60°C, and the pressure is 0.4Mpa. After the lamination, the equipment is stopped to obtain a semi-fin...

Embodiment 2

[0036] The preparation of corn polylactic acid fiber spunlace non-woven fabric: firstly, corn grains are used as raw materials, which are fermented and converted into lactic acid, then polymerized and spun to make corn polylactic acid fibers, and then corn polylactic acid fibers are prepared from corn polylactic acid fibers. Fiber spunlace non-woven fabrics, extraction of corn polylactic acid fibers and preparation of spunlace non-woven fabrics can all be done in any way known to those skilled in the art;

[0037] Preparation of corn polylactic acid fiber fabric: put the corn polylactic acid fiber spunlace non-woven fabric prepared above and 2 μm thick TPEE breathable film on the self-made equipment, turn on the equipment, and laminate the TPEE breathable film to the corn polylactic acid fiber water The surface of the non-woven fabric is punctured, the lamination temperature is 50°C, and the pressure is 0.6Mpa. After the lamination, the equipment is stopped to obtain a semi-fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com