Composite flocculation medicine powder for wastewater treatment of flexography ink and application of medicine powder

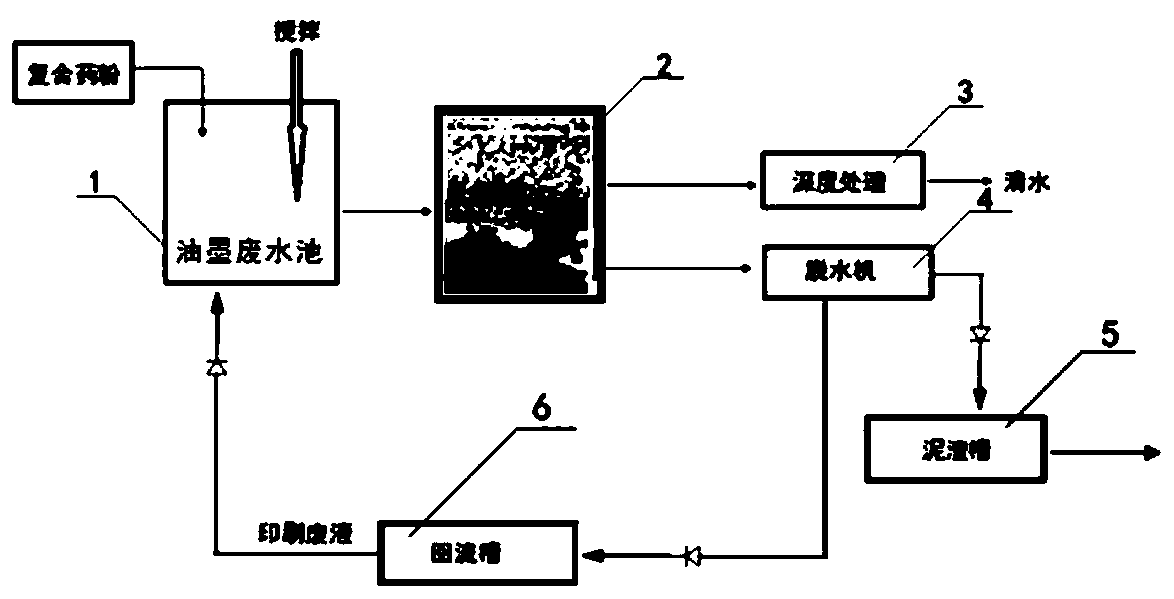

A flexographic printing and wastewater treatment technology, which is applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Changes in wastewater composition and other problems, to achieve good polymerization precipitation and surface adsorption, good decolorization, fast flocculation and sedimentation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This composite flocculation powder for flexographic printing ink wastewater treatment is composed of polyacrylamide, ferric chloride, aluminum sulfate, chitosan, dolomite powder and clay; and each composition is prepared according to the following weight ratio, Among them, polyacrylamide 0.5%; ferric chloride 10%; aluminum sulfate 30%; chitosan 9.5%; dolomite powder 30%; clay 20%.

[0050] The polyacrylamide used can be cationic polyacrylamide, anionic polyacrylamide or nonionic polyacrylamide.

Embodiment 2

[0052] This composite flocculation powder for flexographic printing ink wastewater treatment is composed of polyacrylamide, ferrous sulfate, polyaluminum chloride, chitosan, dolomite powder, and clay; and each composition is prepared according to the following weight ratio , of which polyacrylamide 0.5%; ferrous sulfate 10%; aluminum chloride 30%; chitosan 9.5%; dolomite powder 30%; clay 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com