A hole-forming extraction tube for ultrasonic inspection of pile foundation quality

An ultrasonic and quality technology, which is applied in the test of foundation structure, sheet pile wall, foundation structure engineering, etc., can solve the problems of short service life and complicated operation of the extraction pipe, so as to reduce the service life, improve the lubrication effect and save money. The effect of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

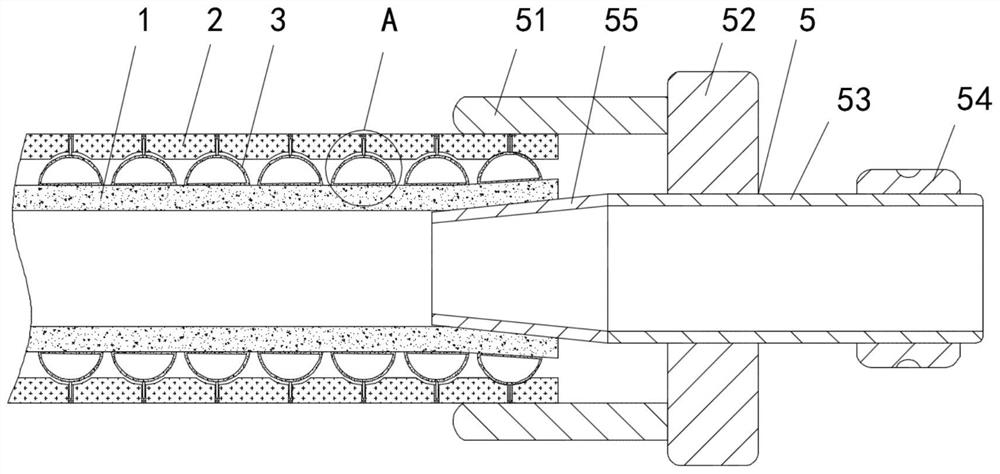

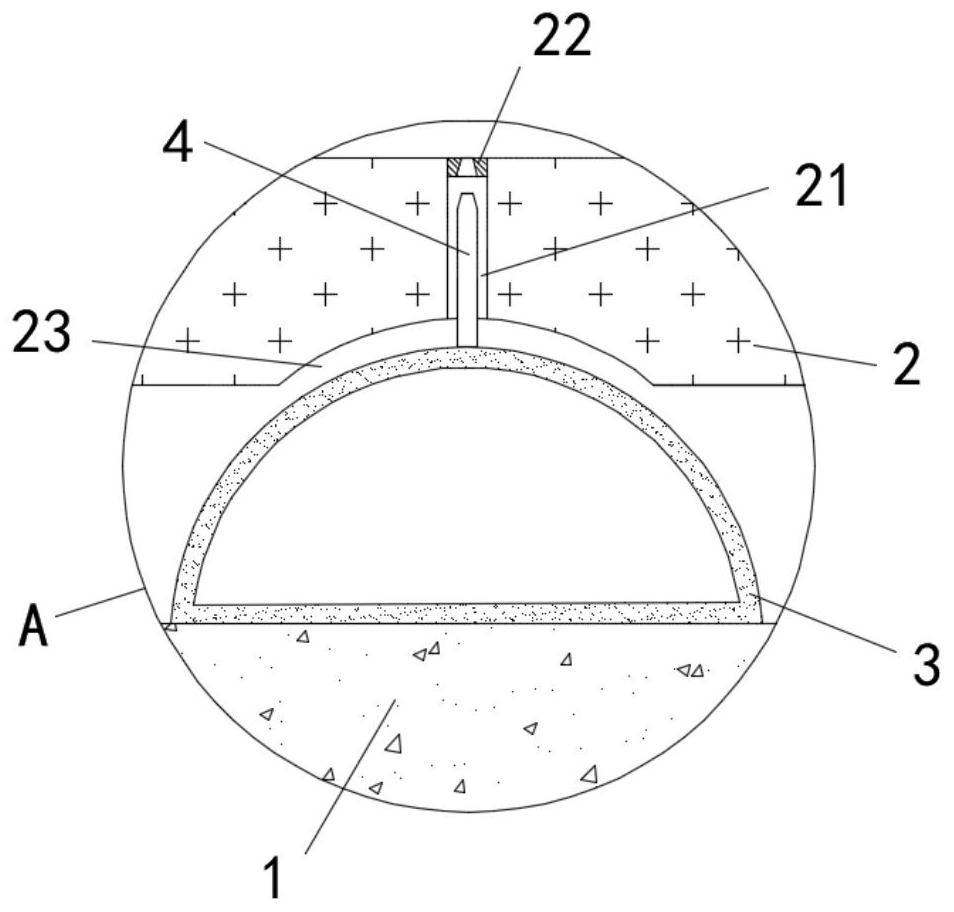

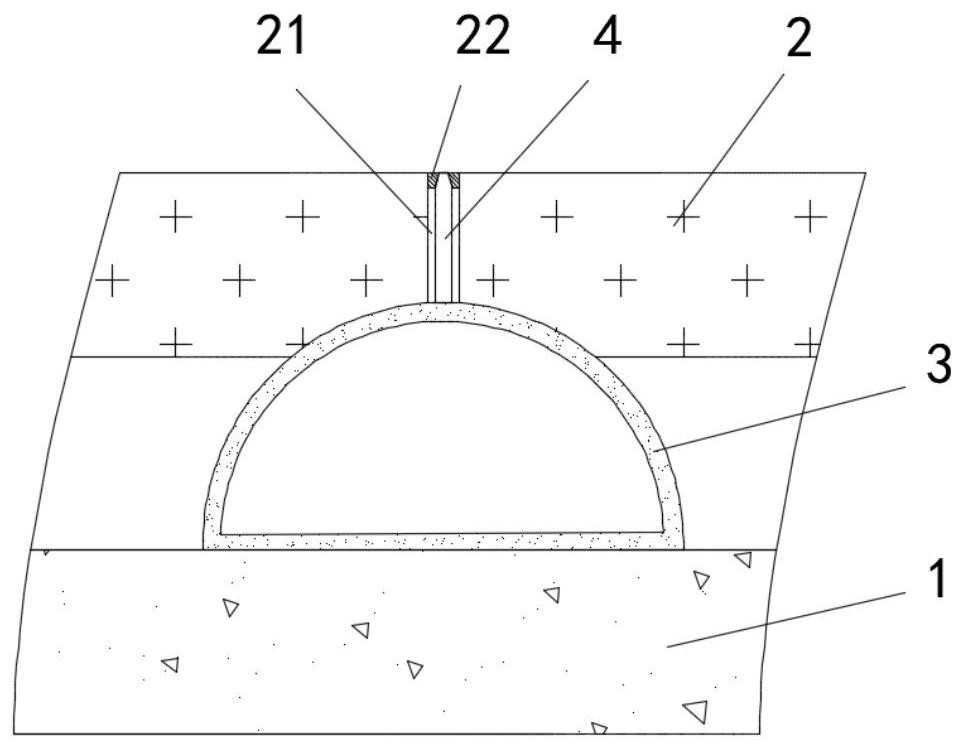

[0026] refer to Figure 1-4 , a hole-forming extraction tube for ultrasonic testing of pile foundation quality, including an inner tube 1 and an outer tube 2. It should be noted that both the inner tube 1 and the outer tube 2 are made of rubber materials, and the outer tube 2 The diameter is 50mm, the inner diameter is 20mm, and the wall thickness is 15mm. The outer diameter of the inner tube 1 is 10mm, the inner diameter is 4mm, and the wall thickness is 3mm. The outer tube 2 is set outside the inner tube 1 and fixed on the outer wall of the inner tube 1. A plurality of annular airbags 3 are socketed. It should be noted that the annular airbag 3 is a telescopic airbag made of rubber material. The cross-section of the annular airbag 3 is set in a semicircle. The force is uniform, which can well play the role of supporting the outer tube 2. The radius of the section of the annular airbag 3 is 4mm. At room temperature, the annular airbag 3 does not contact the outer tube 2, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com