Plate penetrating pipeline opening sealing formwork support frame

A technology for blocking formwork and support frame, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, which can solve concrete leakage, honeycomb hemp surface, etc. , non-compact and other problems, to achieve the effect of convenient production, simple support frame structure, and improved construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The formwork supporting frame for blocking the hole of the through-board pipeline of the present invention includes a supporting plate, a vertical rod, and two diagonal bracing rods.

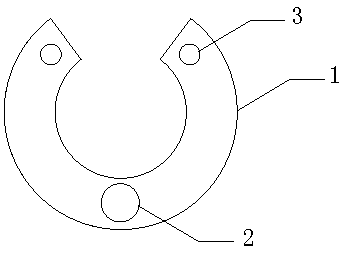

[0027] see now figure 1 , figure 1 It is a schematic plan view of the structure of the template support frame of the embodiment of the present invention. As shown in the figure, the supporting plate is a U-shaped iron plate 1 of a horseshoe, and the top surface of the U-shaped iron plate of the horseshoe is supported on the top of the U-shaped iron plate to support the sealing formwork of the road opening; the annular width of the U-shaped iron plate of the horseshoe is 75mm, and the thickness is 10mm.

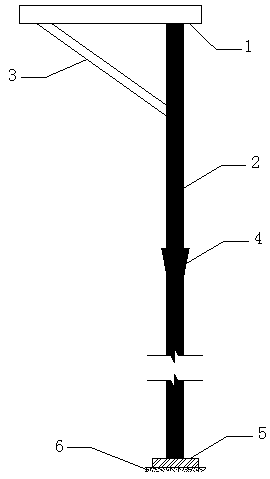

[0028] The vertical rod 2 is an upright steel rod, the length of the steel rod is less than the height of the floor, one end of the steel rod is vertically welded to the connecting end of the U-shaped iron plate of the horseshoe, and the other end of the steel rod is supported on the flo...

Embodiment 2

[0031] figure 2 It is a schematic elevation view of the structure of the formwork support frame in the embodiment of the present invention. The use method of the formwork support frame for blocking the hole of the through-plate pipeline of the present invention:

[0032] (1) After the cleaning of the opening of the through-board pipeline is completed, the formwork is placed on the pallet.

[0033] (2) Insert the standpipe into the supporting plate, and connect the first section of steel pipe and the second section of steel pipe.

[0034] (3) By adjusting the thickness of the backing plate, make the pole under the force state.

[0035] (4) Complete the formwork support for the plugging of the hole of the through-plate pipeline.

[0036] The present invention has substantive features and significant technical progress. The formwork support frame for sealing the opening of the through-slab pipeline of the present invention has low production cost and high turnover times. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com