Bipolar plate, fuel cell stack comprising same, and power generation system

A fuel cell stack and bipolar plate technology, which is applied in the direction of fuel cells, power system fuel cells, fuel cell components, etc., can solve the problems of unfavorable reaction product water discharge, parasitic power increase, poor drainage, etc. , to achieve the effects of easy control, reduced parasitic power, and favorable voltage drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

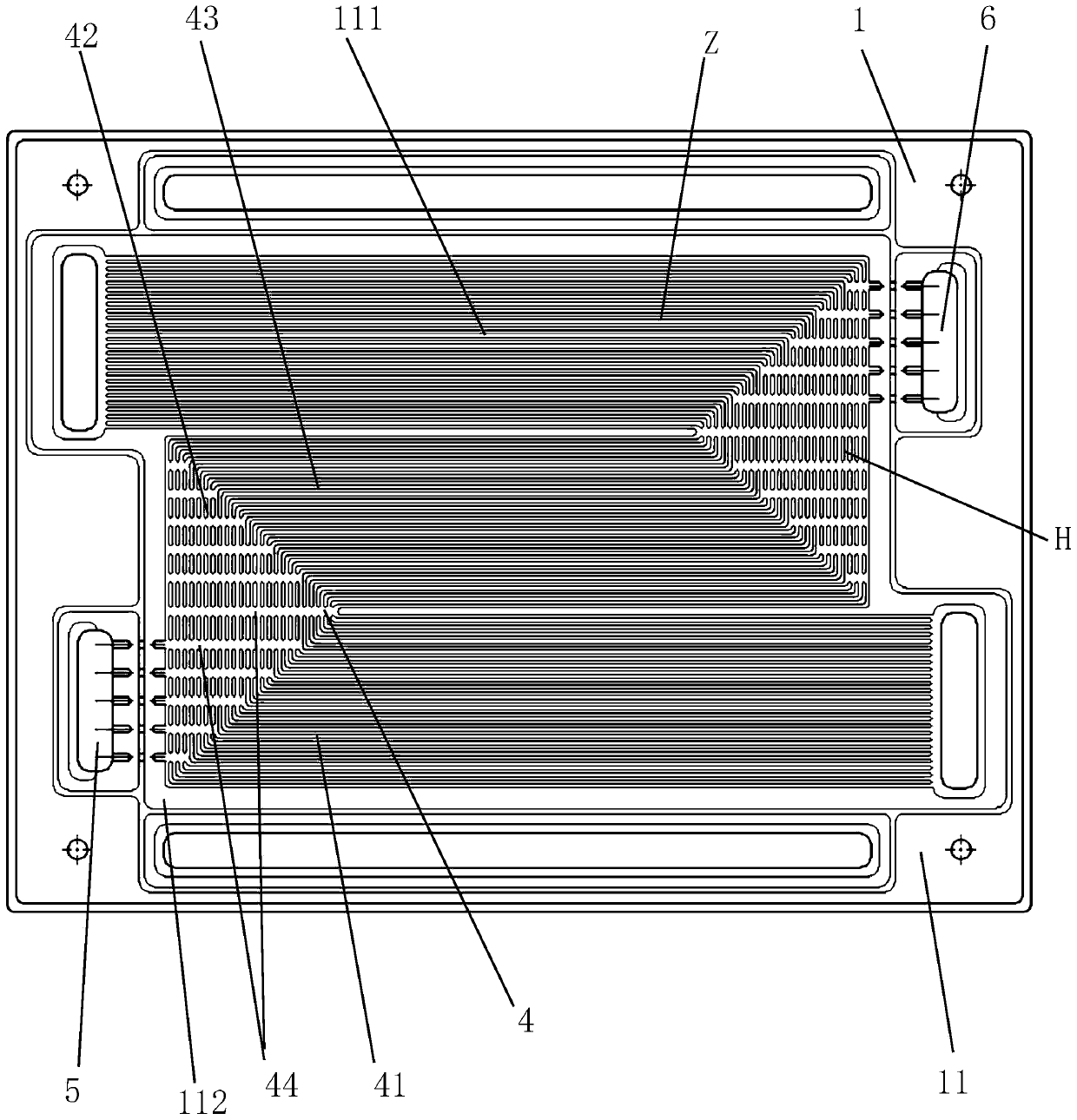

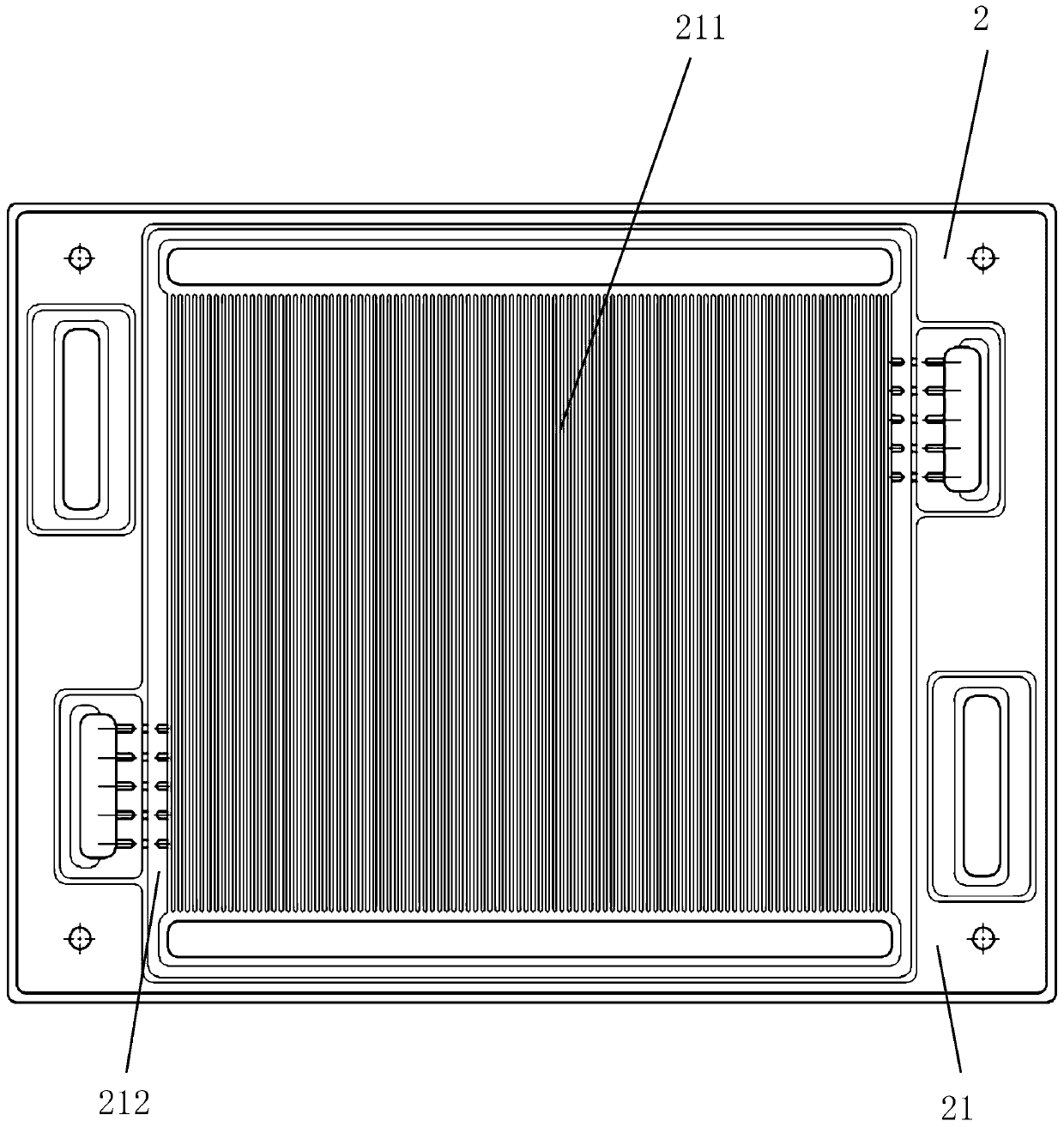

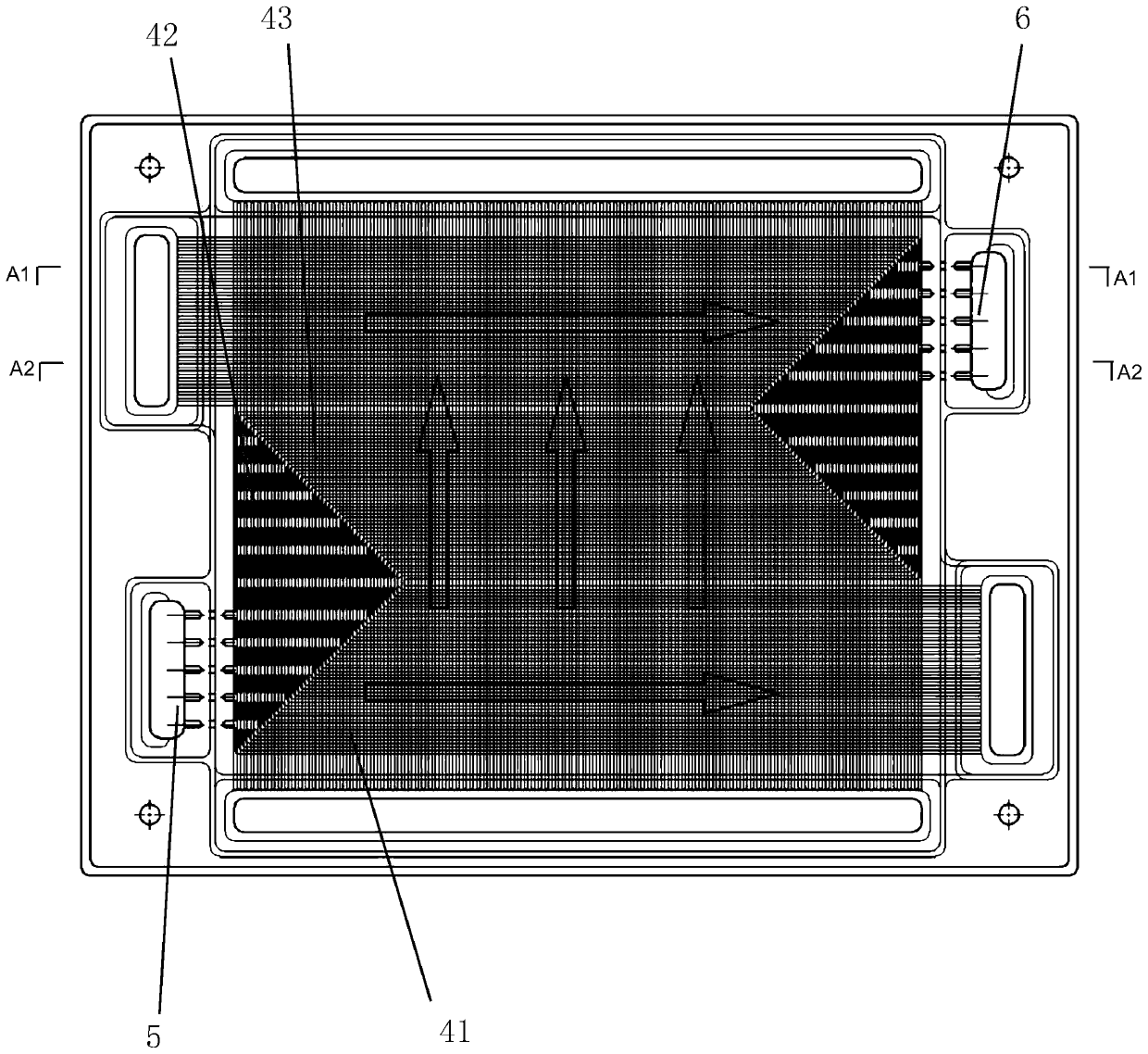

[0055] Such as Figure 1-Figure 3 As shown, the present invention provides a bipolar plate, which is the first embodiment of the present invention, and includes a first plate 1 and a second plate 2. The first plate 1 has a first surface 11 and a second surface 12. , The second electrode plate 2 has a third surface 21 and a fourth surface 22, the second surface 12 of the first electrode plate 1 and the fourth surface 22 of the second electrode plate 2 are bonded together, forming a Coolant runner 3. The first surface 11 of the first electrode plate 1 has a first flow channel 111 and a first reference surface 112, and the second surface 12 has a second flow channel 121 and a second reference surface 122. The third surface 21 of the second electrode plate 2 has a third flow channel 211 and a third reference surface 212, and the fourth surface 22 has a fourth flow channel 221 and a fourth reference surface 222. The first flow passage 111 is a groove formed in the thickness directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com