Midpoint voltage control and common mode voltage suppression method and system of three-level inverter

A three-level inverter, common-mode voltage technology, applied in electrical components, output power conversion devices, AC power input conversion to DC power output, etc., can solve the malfunction of motor protection circuit, neutral point voltage balance ability Limited, insufficient mid-point voltage regulation ability, etc., to achieve the effect of reducing common-mode voltage and mid-point voltage fluctuation, and improving mid-point voltage balance ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

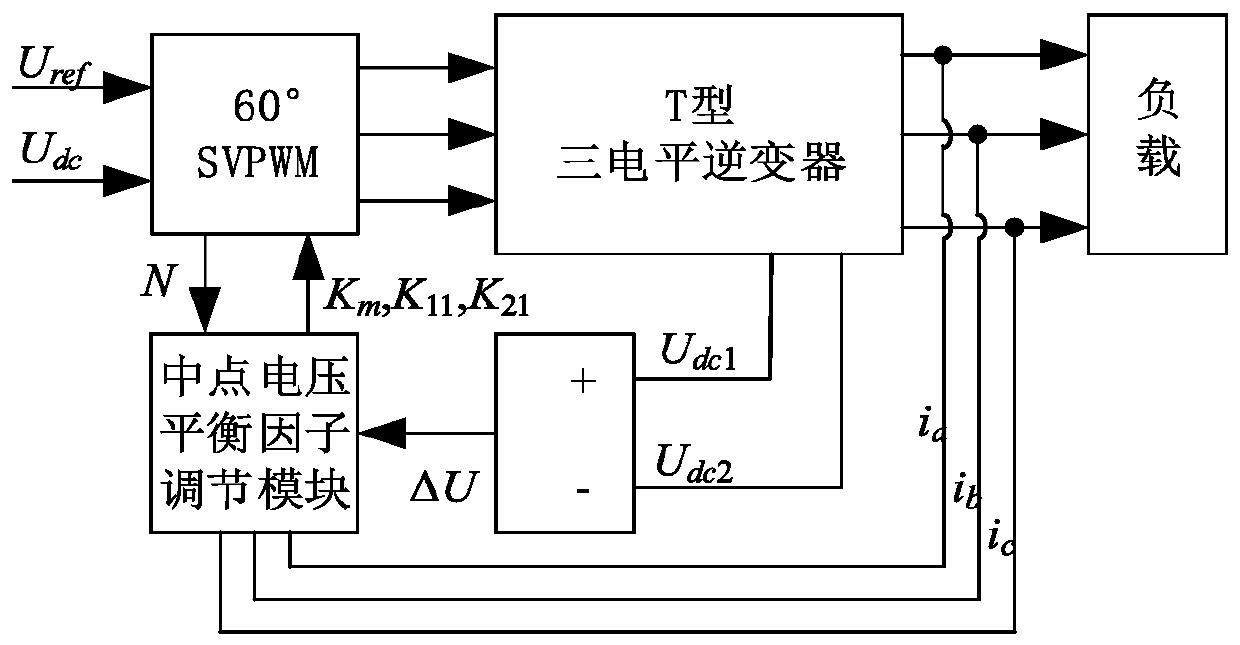

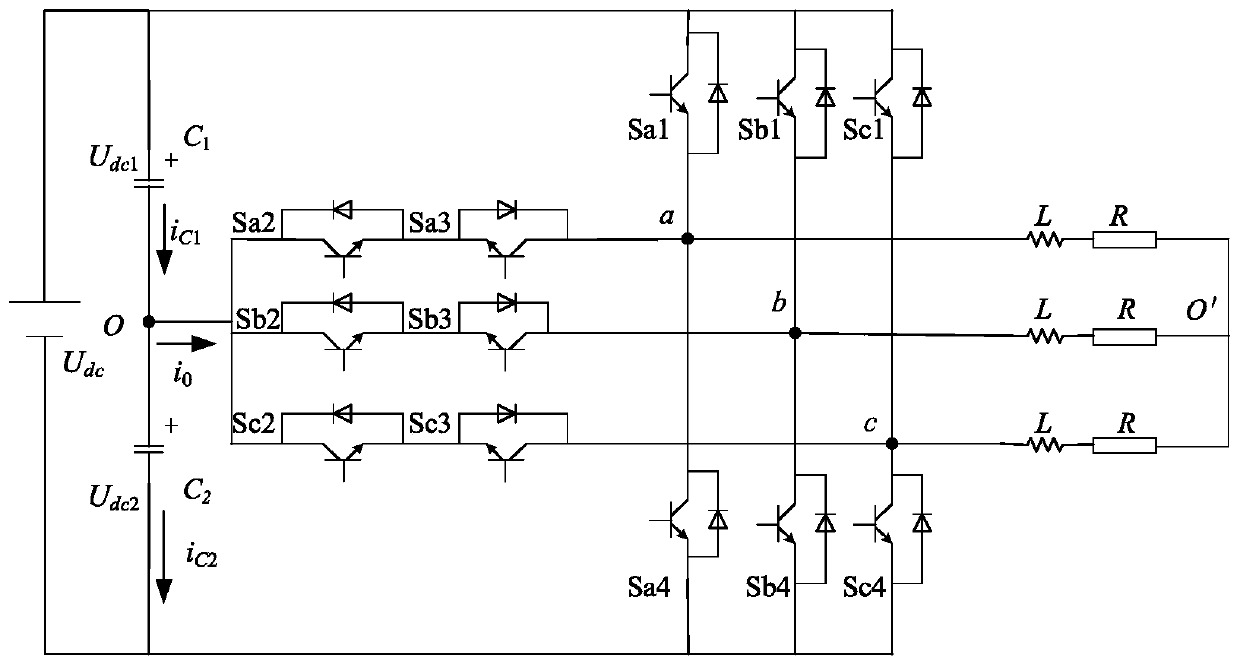

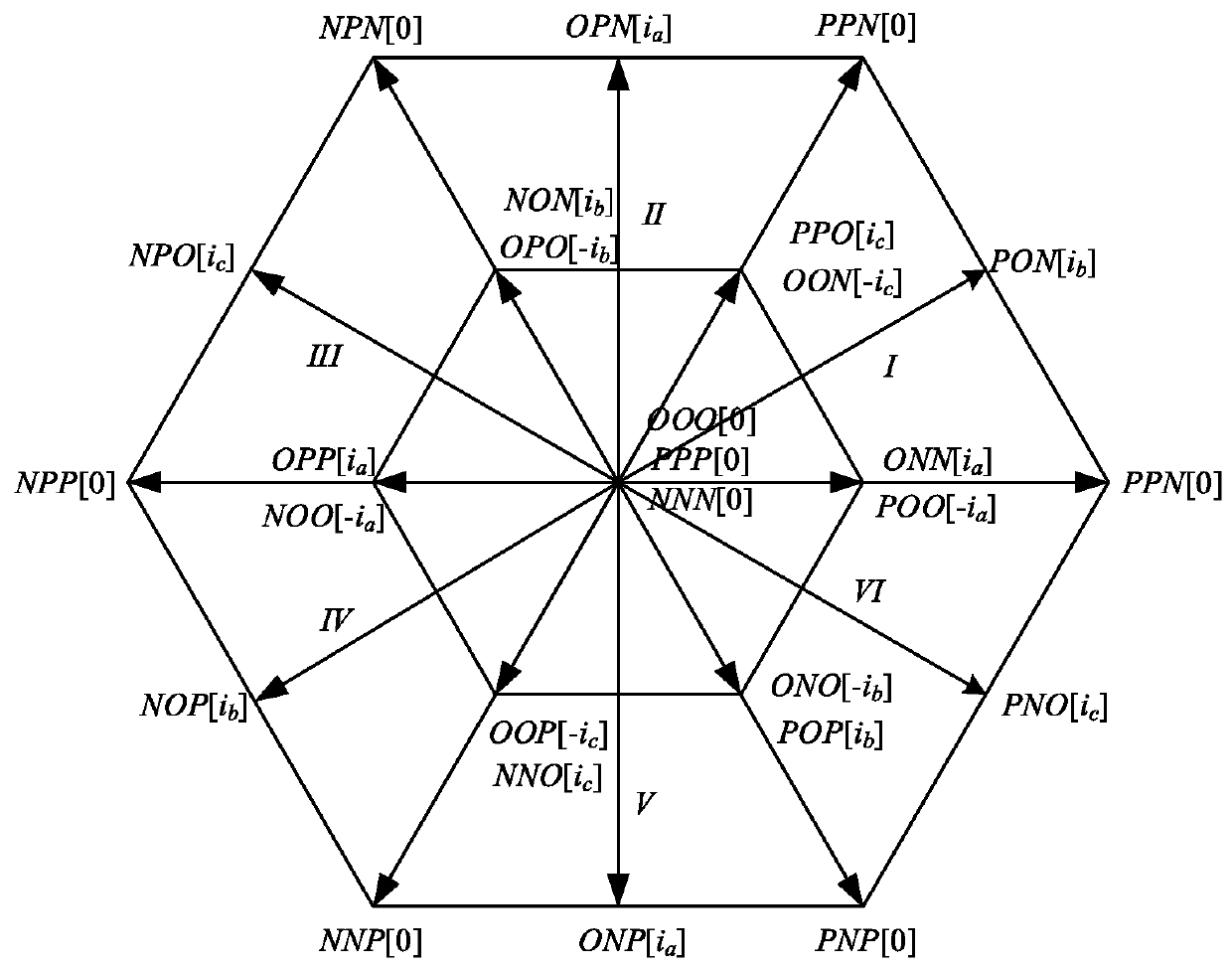

[0046] The mid-point voltage control and common-mode voltage suppression method of the three-level inverter based on the variable virtual vector provided by the present invention is specifically as follows: by rationally constructing virtual small vectors and medium vectors, each virtual vector can be controlled in one control cycle The change in charge at the midpoint is zero. At the same time, when constructing the virtual vector, vectors that cause an increase in the common-mode voltage are eliminated to ensure that the common-mode voltage of the output voltage is minimized. By detecting the voltage difference between the upper and lower capacitors and the three-phase current in real time, an appropriate midpoint voltage balance factor is selected, so that charges flow into or out of the midpoint to adjust the midpoint voltage balance....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com