High-strength steel material having enhanced resistance to brittle crack propagation and break initiation at low temperature and method for manufacturing same

A high-strength steel, low-temperature technology, applied in the direction of manufacturing tools, furnaces, heat treatment equipment, etc., can solve the problems that it is difficult to fully ensure the fracture initiation resistance and fracture propagation resistance, and achieve the effect of improving fracture propagation resistance and fracture initiation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0126] In the following description, example embodiments of the present disclosure will be described in more detail. It should be noted that the exemplary embodiments are provided to describe the present disclosure in more detail, not to limit the present disclosure.

[0127] Slabs having compositions as shown in Table 1 below were heated, hot rolled and cooled under the conditions listed in Table 2 below, and steel samples were produced.

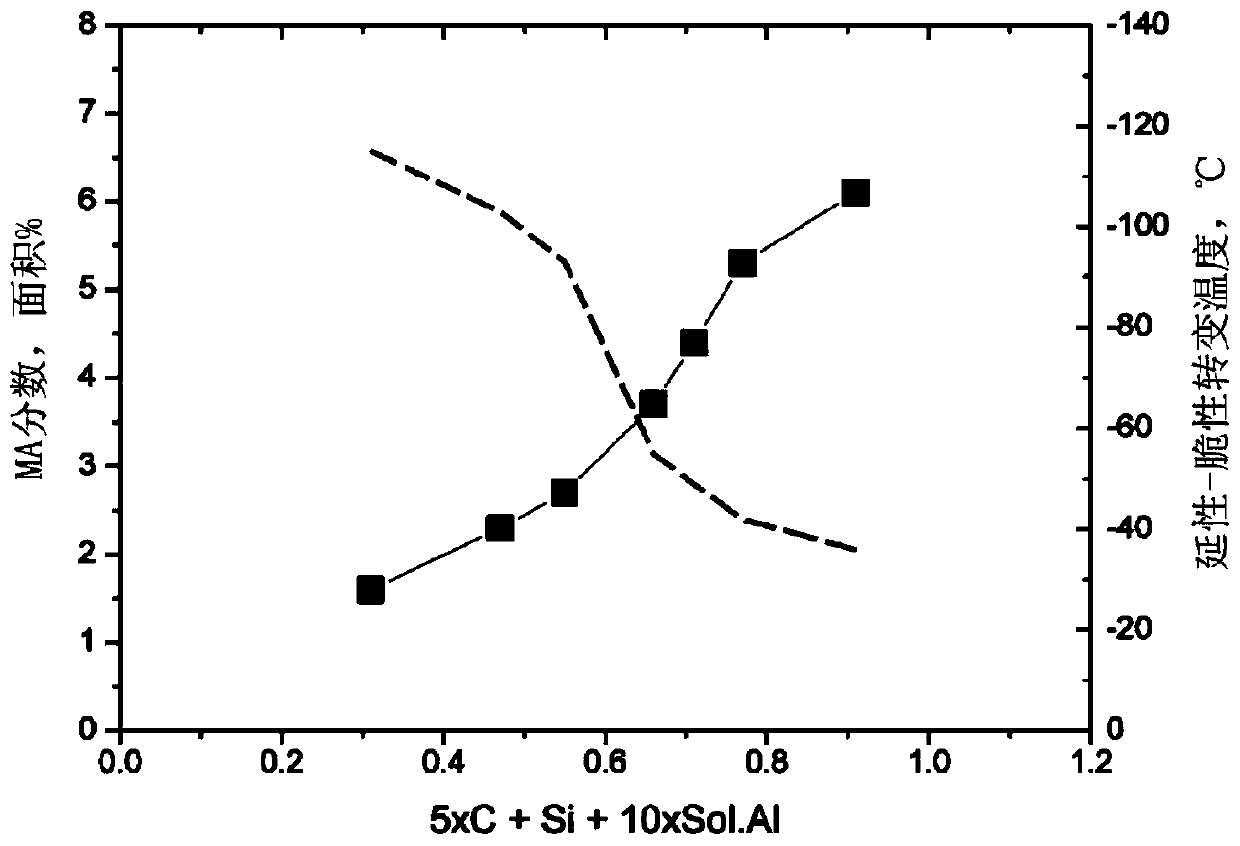

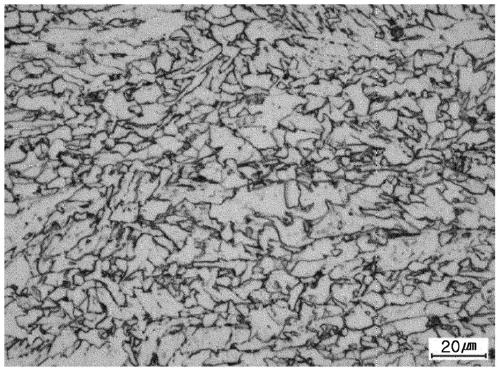

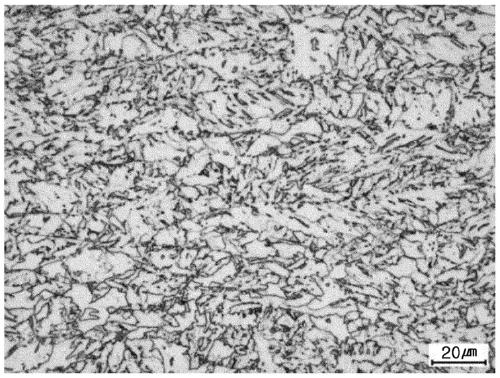

[0128] The microstructures of the manufactured steel samples were observed, properties were measured, and the results are listed in Table 3 below.

[0129]In addition, the fabricated steel specimens were welded with the welding heat input listed in Table 2 below, and the impact energy value (-60°C) and CTOD value (-40°C) of the welding heat-affected zone (SCHAZ) were determined by The measurements are listed in Table 3 below. Since the impact energy value (-60°C) and CTOD value (-40°C) of the steel sample are higher than the impact energy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com