A kind of metal bond grinding tool and preparation method thereof

A metal bond and abrasive tool technology, which is applied in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problems of diamond holding force drop, diamond abrasive grain falling off, and insufficient high temperature performance of metal bond, so as to prevent Effects of premature detachment, increased bond strength, and altered low creep strength characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

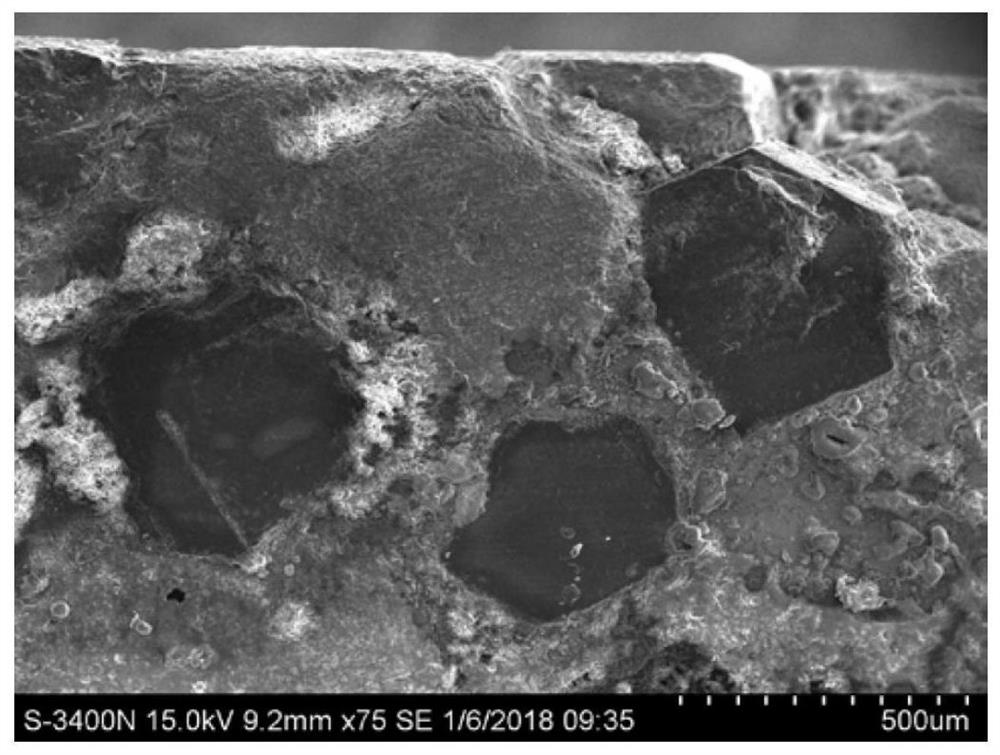

Image

Examples

Embodiment 1

[0044] The present embodiment is the preparation of metal bond abrasive, comprising the following steps:

[0045] FeAl powder and NiAl powder are mixed in a vacuum glove box at a weight ratio of 1:2, and the parts by weight are 87.9 parts in total, of which 29.3 parts by weight of FeAl and 58.6 parts by weight of NiAl; FeAl powder The particle size of NiAl powder is 18 μm, and the particle size of NiAl powder is 18 μm; only B element is added as a strengthening sintering aid, and its weight part is 0.1 parts, and the particle size is 10 μm; take 12 parts by mass fraction of diamond abrasive grains, and the particle size is 48 head. Put the above-mentioned metal bond and abrasive into a ball mill and mix thoroughly. The speed of the ball mill is 250r / min, the ball milling time is 3h, and the ball-to-material ratio is 10:1. Put the mixed ball-milling mixture into a cemented carbide cold-press mold for cold-press forming, the pressure is 200MPa, and the green compact density of ...

Embodiment 2

[0048] The present embodiment is the preparation of metal bond abrasive, comprising the following steps:

[0049] FeAl powder and NiAl powder are mixed in a vacuum glove box at a weight ratio of 1:2, and the parts by weight are 78.9 parts in total, of which 26.3 parts by weight of FeAl and 52.6 parts by weight of NiAl; FeAl powder The particle size of NiAl powder is 38 μm, the particle size of NiAl powder is 45 μm; the parts by weight of sintering aid are 10.1 parts in total, the parts by weight of B powder are 0.1 parts, and the particle size is 10 μm; the parts by weight of Cr powder are 2 parts , its particle size is 25 μm; the parts by weight of Si powder is 2 parts, its particle size is 25 μm; the parts by weight of Zr powder is 2 parts, its particle size is 18 μm; the parts by weight of Ti powder is 2 parts, its The particle size is 23μm; Al 2 o 3 The parts by weight of the powder are 2 parts, and its particle size is 300nm; 11 parts by mass of diamond abrasive grains ...

Embodiment 3

[0051] The present embodiment is the preparation method of metal bond grinding tool, comprises the following steps:

[0052] FeAl powder and NiAl powder are mixed in a vacuum glove box at a weight ratio of 1:2, and the parts by weight are 69.9 parts in total, of which 23.3 parts by weight of FeAl and 46.6 parts by weight of NiAl; FeAl powder The particle size of NiAl powder is 58 μm, the particle size of NiAl powder is 53 μm; the weight parts of sintering aids are 20.1 parts in total. Among them, the weight parts of B powder is 0.1 parts, and its particle size is 13 μm; the weight parts of Cr powder is 2 Parts, its particle size is 23 μm; The parts by weight of Si powder is 2 parts, its particle size is 38 μm; The parts by weight of Zr powder is 2 parts, its particle size is 23 μm; The parts by weight of Ti powder is 2 parts, Its particle size is 38μm; Al 2 o 3 The parts by weight of Cu powder is 2 parts by weight, and its particle size is 200nm; the parts by weight of Cu po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com