Method for preparing algae powder by high-density culture of Isochrysis globosa

A high-density culture technology for Isochrysis globosa, which is applied in the field of algae cultivation, can solve the problems of low growth rate and culture density, lack of culture conditions and anti-pollution ability of Isoflagellates, and achieve complete dehydration, simple and feasible process, and high moisture content. The effect of content control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

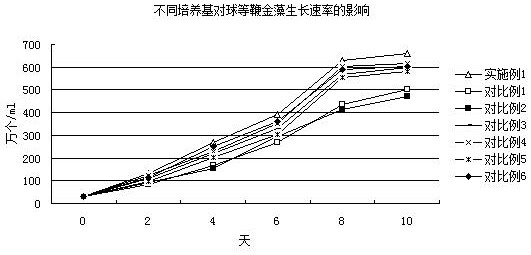

Embodiment 1

[0028]The method for preparing algae powder by high-density culture of Isochrysis globosa, inoculating Isochrysis globosa (taking Isochrysis globosa 8071 species as an example) cultivated to the logarithmic growth phase into a culture container containing medium, inoculating The initial density is 300,000 / ml, the light intensity is 4000lux, cultured at 24°C, the light-to-dark ratio is 18:6, the ventilation rate is 0.2vvm, cultured for 10 days, and the algae liquid is collected;

[0029] Centrifuge the algae liquid in a disc centrifuge at 4000r / min for 10min, collect the precipitate, then place it at a low temperature of -20°C, freeze it for 30min, then place it in a vacuum drying oven at 50°C, and dry it to constant weight , collect the dried algae bodies, put them in a universal grinder for crushing, pass through a 200-mesh sieve, and collect the under-sieves to obtain the product.

[0030] The medium for cultivating Isochrysis globosa comprises the following components: KNO ...

Embodiment 2

[0032] The method for preparing algae powder by high-density cultivation of Isochrysis globosa is to inoculate Isochrysis globosa cultivated to the logarithmic growth phase into a culture container containing medium, the initial density of inoculation is 200,000 / ml, and the light intensity is 4000lux , cultured at 25°C, the light-dark ratio was 18:6, the ventilation rate was 0.2vvm, cultured for 12 days, and the algae liquid was collected;

[0033] Centrifuge the algae liquid in a disc centrifuge at 4500r / min for 8min, collect the precipitate, then place it at a low temperature of -20°C, freeze it for 30min, then place it in a vacuum drying oven at 50°C, and dry it to constant weight , collect the dried algae bodies, put them in a universal grinder for crushing, pass through a 200-mesh sieve, and collect the under-sieves to obtain the product.

[0034] The medium for cultivating Isochrysis globosa comprises the following components: KNO 3 110mg / L, phytic acid 15mg / L, KH 2 P...

Embodiment 3

[0036] The method for preparing algae powder by cultivating Isochrysis globosa at high density, inoculating Isochrysis globosa that has been cultivated to the logarithmic growth phase into a culture container containing a medium, the initial inoculation density is 300,000 / ml, and the light intensity is 4000lux , cultivated at 24°C, the light-dark ratio was 18:6, the ventilation rate was 0.2vvm, cultivated for 9 days, and collected the algae liquid;

[0037] Centrifuge the algae liquid in a disc centrifuge at 4000r / min for 8 minutes, collect the precipitate, then place it at a low temperature of -20°C, freeze it for 50 minutes, then place it in a vacuum drying oven at 55°C, and dry it to constant weight , collect the dried algae bodies, put them in a universal grinder for crushing, pass through a 200-mesh sieve, and collect the under-sieves to obtain the product.

[0038] The medium for cultivating Isochrysis globosa comprises the following components: KNO 3 110mg / L, phytic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com