Lithium mineralized composite sintered active carbon filtering core based on natural rock, and preparation method thereof

A technology for sintering activated carbon and natural rocks, which is applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problem of lithium mineralization being blank, and achieve the effect of avoiding adverse effects, simple process, and increasing lithium content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

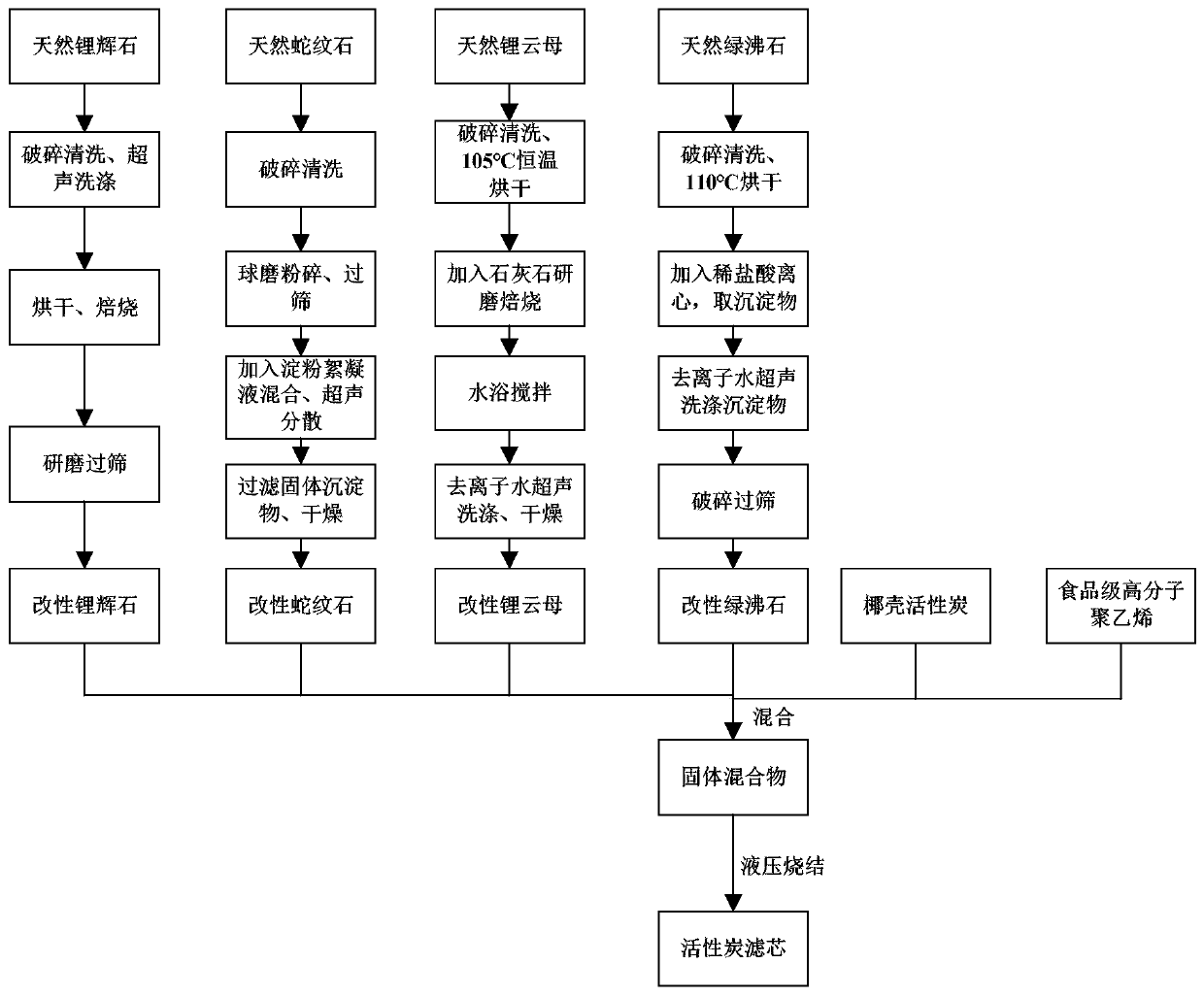

Method used

Image

Examples

preparation example Construction

[0025] The preparation process of the modified serpentine is as follows: crush the natural serpentine, wash it repeatedly with tap water until there are no impurities, then perform ball milling and crush it, and pass through 200 mesh and 400 mesh sieves; boil deionized water for 20 minutes, and stir while adding starch , and then boiled to obtain a 200mg / L starch solution. NaOH was added to adjust the pH of the starch solution to 11-12 to obtain a starch floc; Mix and stir, then ultrasonically treat for 60s to disperse, after settling for 30min, suck out the supernatant, keep the solid precipitate, filter the solid precipitate with filter paper, and then dry to obtain the modified serpentine; it can be removed by flocculation Most of the heavy metal compounds such as iron and chromium mixed in serpentine.

[0026] The preparation process of modified lepidolite is as follows: crush and screen natural lepidolite, rinse repeatedly with deionized water until the water is clear and...

Embodiment 1

[0036] Weigh 65g of modified spodumene, 8g of modified serpentine, 15g of modified lepidolite, 45g of modified green zeolite, 90g of 80-325 mesh coconut shell activated carbon, and 75g of food-grade high molecular polyethylene. Put the raw material into a hydraulic mold and sinter for 40 minutes at a temperature of 200°C and a pressure of 15 MPa; cool and remove the film to obtain a large T filter element of lithium mineralized composite sintered activated carbon.

[0037] Install this big T filter element in the pure water outlet of the 800G reverse osmosis water purifier, control the flow rate of the water outlet at 1.0L / min, first flush with water for 10 minutes, and then pass the water for 1 hour after flushing, then close the inlet and outlet of the filter element and soak for 30 minutes Then open the water inlet and outlet of the filter element in turn, take 500mL water sample for routine index and lithium content test, the measured lithium content in the water sample is ...

Embodiment 2

[0040] Weigh 70g of modified spodumene, 6g of modified serpentine, 12g of modified lepidolite, 42g of modified green zeolite, 85g of coconut shell activated carbon of 80-325 mesh, and 72g of food-grade high molecular polyethylene. The raw materials were put into a hydraulic mold and sintered for 40 minutes at a temperature of 150°C and a pressure of 10 MPa; cooled and stripped to obtain a small T filter element of lithium mineralized composite sintered activated carbon.

[0041] Install this small T filter element in the pure water outlet of the 800G reverse osmosis water purifier, control the flow rate of the water outlet at 1.0L / min, first flush with water for 10 minutes, and then pass the water for 1 hour after flushing, then close the inlet and outlet of the filter element and soak for 30 minutes Then open the water inlet and outlet of the filter element in turn, take 500mL water sample for routine index and lithium content test, the lithium content in the water sample is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com