Grinding material continuous and automatic feed device capable of achieving pressure stabilization and flow stabilization

A technology of constant voltage, steady flow and automatic supply. It is applied in the field of mechanical abrasive jets, which can solve the problems of inability to automatically adjust the concentration of abrasives for continuous safe operation, and achieve the advantages of ensuring safety and stability, strong pressure resistance and improving pressure resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

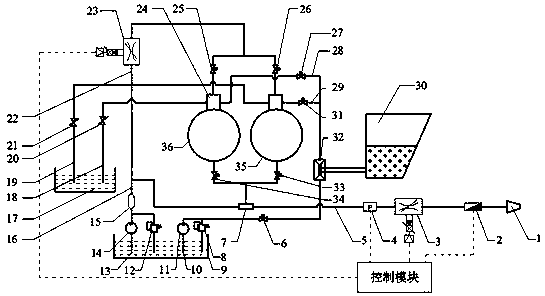

[0023] Combine below figure 1 The present invention is further described.

[0024] see figure 1 , a kind of stable pressure and steady flow abrasive continuous automatic supply warning device designed by the present invention mainly includes high-pressure abrasive tank, high-pressure water pipeline, low-pressure water pipeline, feeding pipeline, abrasive water jet pipeline 5 and valves arranged on each pipeline And sensors, and controllers.

[0025] The high-pressure abrasive tank is a spherical double tank, namely two spherical high-pressure abrasive tanks 35, 36. The upper part of the tank is equipped with a valve seat 24, and the valve seat is respectively connected to the feeding pipeline, the high-pressure water pipeline and the low-pressure water pipeline. The high-pressure ball valves 20, 21 are connected to the pool 17 at the pipeline outlet.

[0026] The two spherical high-pressure abrasive tanks 35, 36 are connected to the mixing chamber 7 through two pneumatic ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com