Cloth material infiltration system

A pre-soaking and dipping tank technology, which is applied in the direction of coating, etc., can solve the problems of hidden dangers in the quality of copper clad laminates, difficult air bubbles, large difference, etc., and achieve the effect of high appearance quality and good wetting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

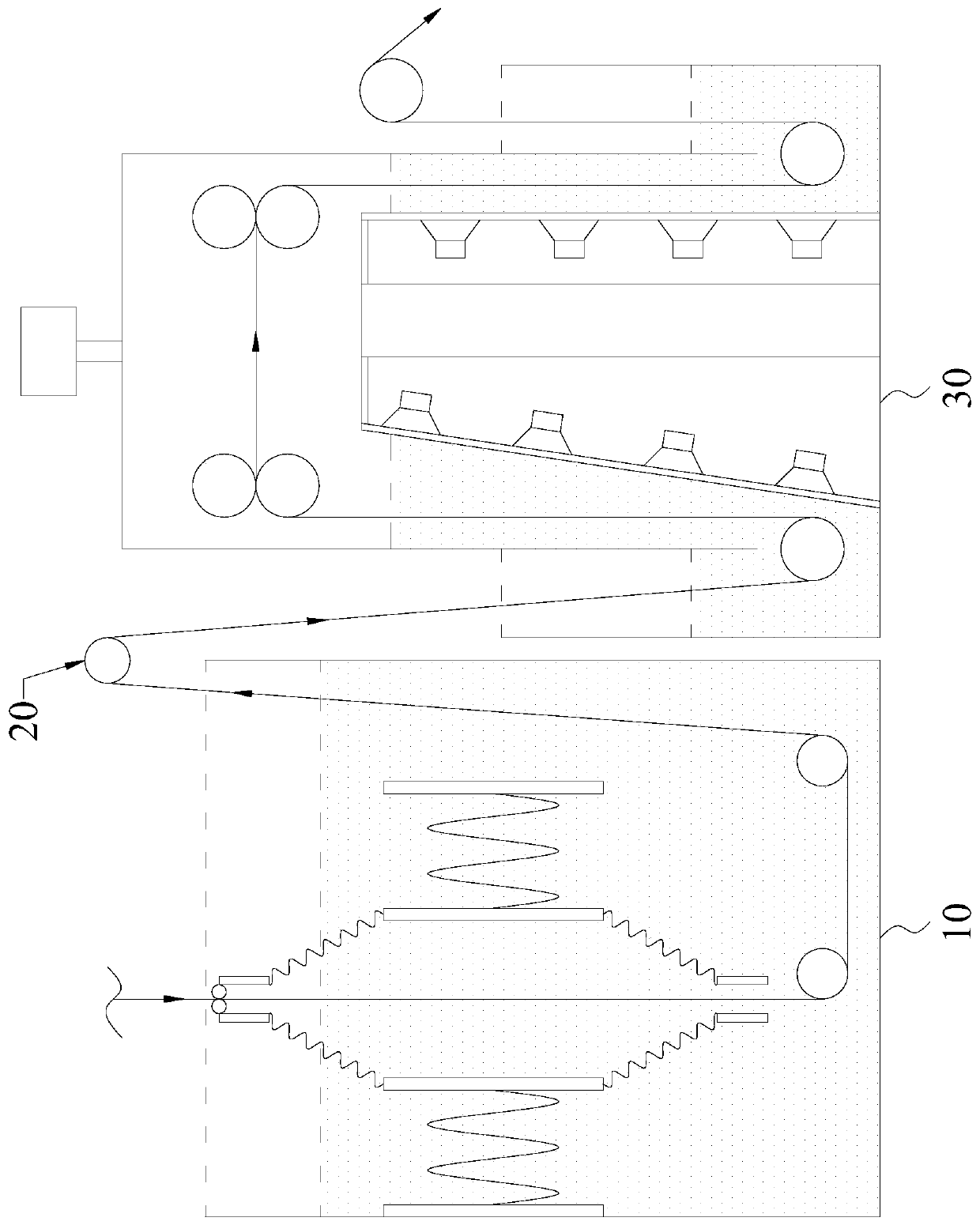

[0033] like figure 1As shown, the cloth-like material soaking system includes a pre-preg device 10 for initial pre-impregnation of the cloth-like material, a dipping device 30 for pre-impregnating the cloth-like material again, a pre-preg device 10 and a dipping device 30 between the first guide rollers 20 . For the convenience of description, the cloth material in this embodiment is glass fiber cloth. After being pre-impregnated by the prepreg device 10, the glass fiber cloth passes through the first guide roller 20 and then enters the dipping device 30 for dipping operation. The glue used for dipping can be epoxy resin adhesive.

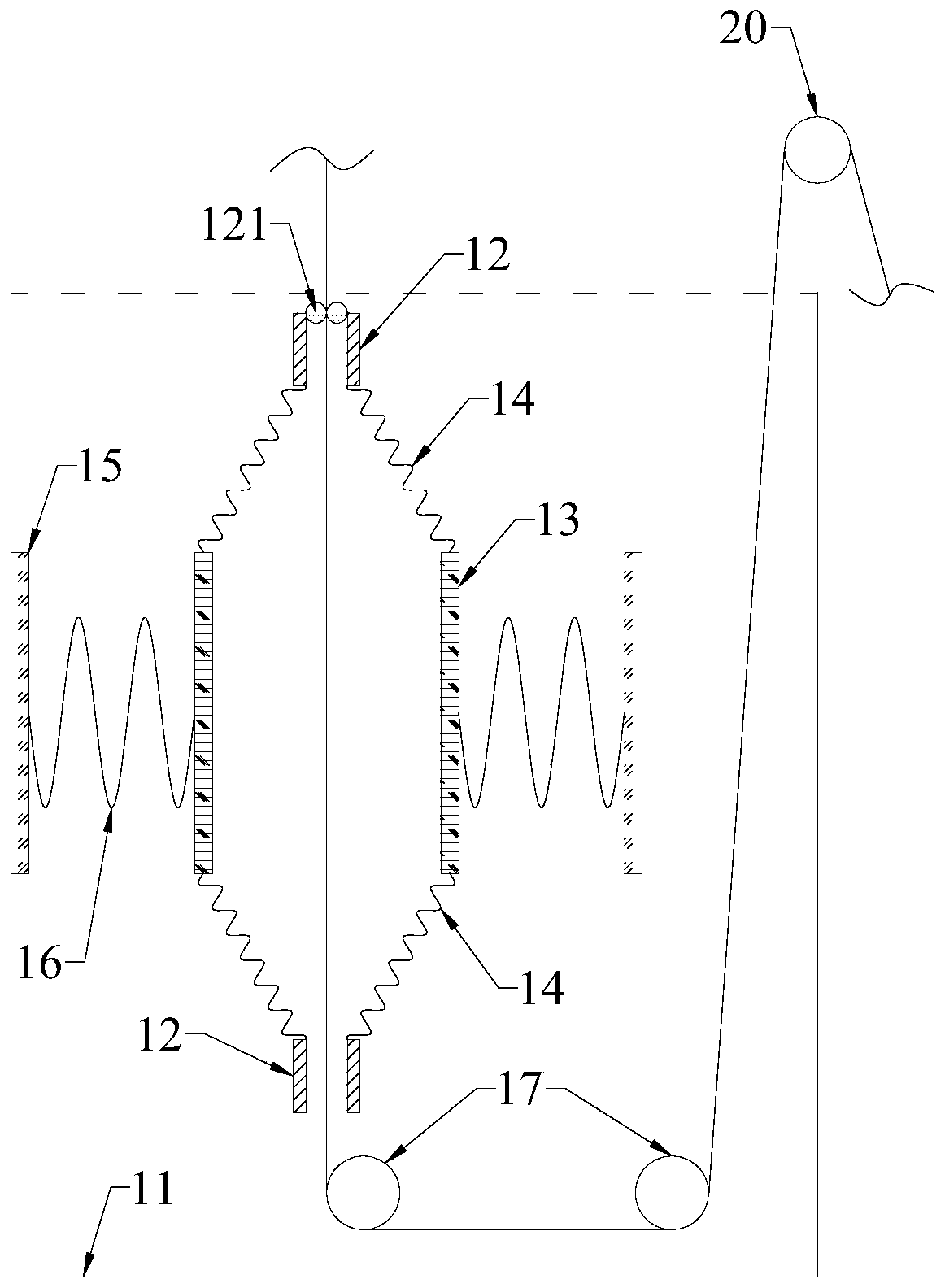

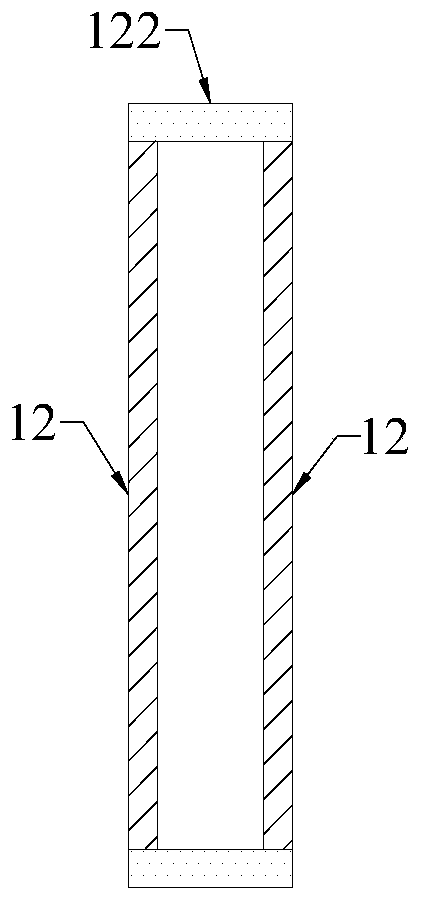

[0034] like figure 2 , 3 As shown, the prepreg device 10 includes a prepreg tank 11 with the notch facing upwards, a pair of axially symmetrical vertical frames 12, and a pair of axially symmetrical extrusion bowls. The lower part of the vertical frame 12 is connected to the There is a gap between the bottom of the prepreg tank 11, and a verti...

Embodiment 2

[0049] The glass fiber cloth is only pre-impregnated in the prepreg device 10 to obtain a soaked sheet. After drying the soaked sheet to make a PP sheet, the pass rate of the PP sheet does not exceed 56.8%. Wherein, in this embodiment, the operating parameters of the glass fiber cloth in the prepreg device 10 are exactly the same as those of the prepreg device 10 in Embodiment 1.

Embodiment 3

[0051] The glass fiber cloth passes through the commonly used dipping tank again after the prepreg device 10, such as the main dipping tank when Guangdong Shengyi Technology Co., Ltd. produces FR4 type PP. There are only a few rotating rollers inside the main dipping tank. After the impregnation sheet obtained after passing through the main dipping tank is dried to make a PP sheet, the qualified rate of the PP sheet is 82.1%. Wherein, in this embodiment, the operating parameters of the glass fiber cloth in the prepreg device 10 are exactly the same as those of the prepreg device 10 in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com