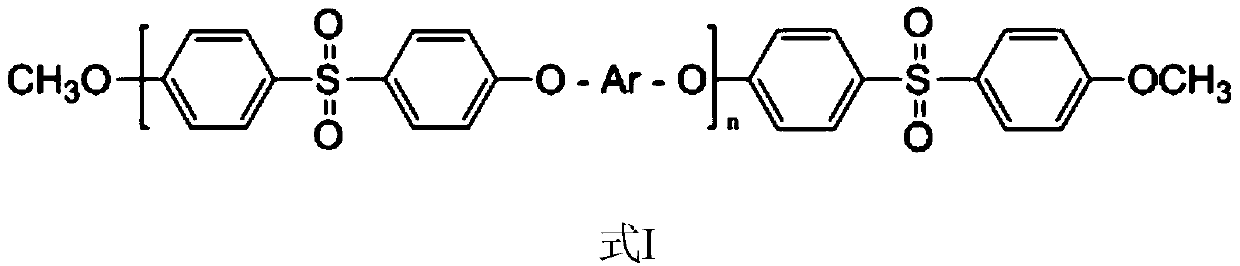

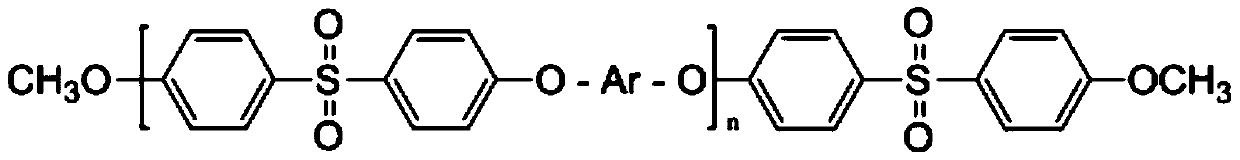

Low-chlorine-content terminated sulfone polymer, preparation method and application thereof

A technology of polymer and chlorine content, which is applied in the field of special engineering plastics, can solve the problems that cannot meet the requirements of low halogen content of electronic appliances, and achieve the effect of low Cl- end group content and complete reaction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

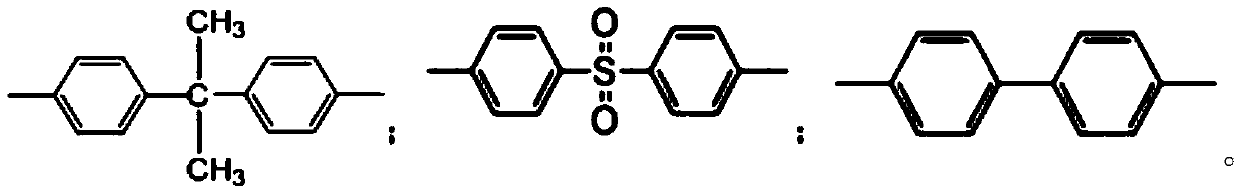

[0055] The preparation method of a kind of low chlorine content capped sulfone polymer of the present invention comprises the following steps:

[0056] (1) Salt formation reaction: under a protective atmosphere, add dihydroxy aromatic monomer (HO-Ar-OH) and dichlorodiphenyl sulfone monomer, then add solvent, stir and heat up until the monomer dissolves until the solution is transparent, Then add salt forming agent (alkali metal carbonate M 2 CO 3 ), then add xylene, continue to stir and heat up to the beginning of the salt-forming reaction, the water produced in the system and the azeotrope generated by xylene are blown out by the protective gas into the condensation tube, condensed and dripped to the water separator for stratification, the upper layer Xylene was returned to the system again when the collected water yield was close to the theoretical value, it was proved that the salt formation was complete, and then distilled and emitted xylene, the salt formation reaction w...

Embodiment 1

[0063] In this embodiment, a method for preparing a low-chlorine-content end-capped sulfone polymer comprises the following steps:

[0064] (1) Salt-forming reaction: Add 125.15g (0.5mol) of 4,4'-dihydroxydiphenyl to a three-necked flask equipped with a thermometer, a nitrogen pipe, a condensing water separator, and a stirrer in sequence according to the ratio in Table 1 Sulfone and 147.17g (0.5125mol) 4,4'-dichlorodiphenyl sulfone, then add 426g solvent sulfolane, stir and heat up to 80°C to dissolve the monomer until the solution is transparent, add 55.65g sodium carbonate, then add 80mL xylene, Continue to stir and raise the temperature to 140°C to start the salt-forming reaction. The azeotrope formed by the water and xylene produced in the system is blown out by the protective gas into the condenser tube to condense and drop to the water separator for stratification, and the xylene in the upper layer flows back to In the system; keep the temperature in the range of 200°C-2...

Embodiment 2

[0073] In this embodiment, a method for preparing a low-chlorine-content end-capped sulfone polymer comprises the following steps:

[0074] (1) Salt-forming reaction: Add 125.15g (0.5mol) of 4,4'-dihydroxydiphenyl to a three-necked flask equipped with a thermometer, a nitrogen pipe, a condensing water separator, and a stirrer in sequence according to the ratio in Table 1 Sulfone (bisphenol S) and 143.72g (0.5005mol) 4,4'-dichlorodiphenyl sulfone, then add 426g sulfolane solvent, stir and heat up to 80°C to dissolve the monomer until the solution is transparent, add 55.65g sodium carbonate, and then Add 80mL of xylene, continue to stir and raise the temperature to 140°C to start the salt-forming reaction. The azeotrope formed by the water produced in the system and xylene is blown out by the protective gas into the condenser, condensed and dropped to the water separator for stratification. Xylene refluxes into the system again; maintain the temperature in the range of 200°C-210...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com