Cerium-based metal organic framework for Cr (VI) detection, preparation method and application thereof

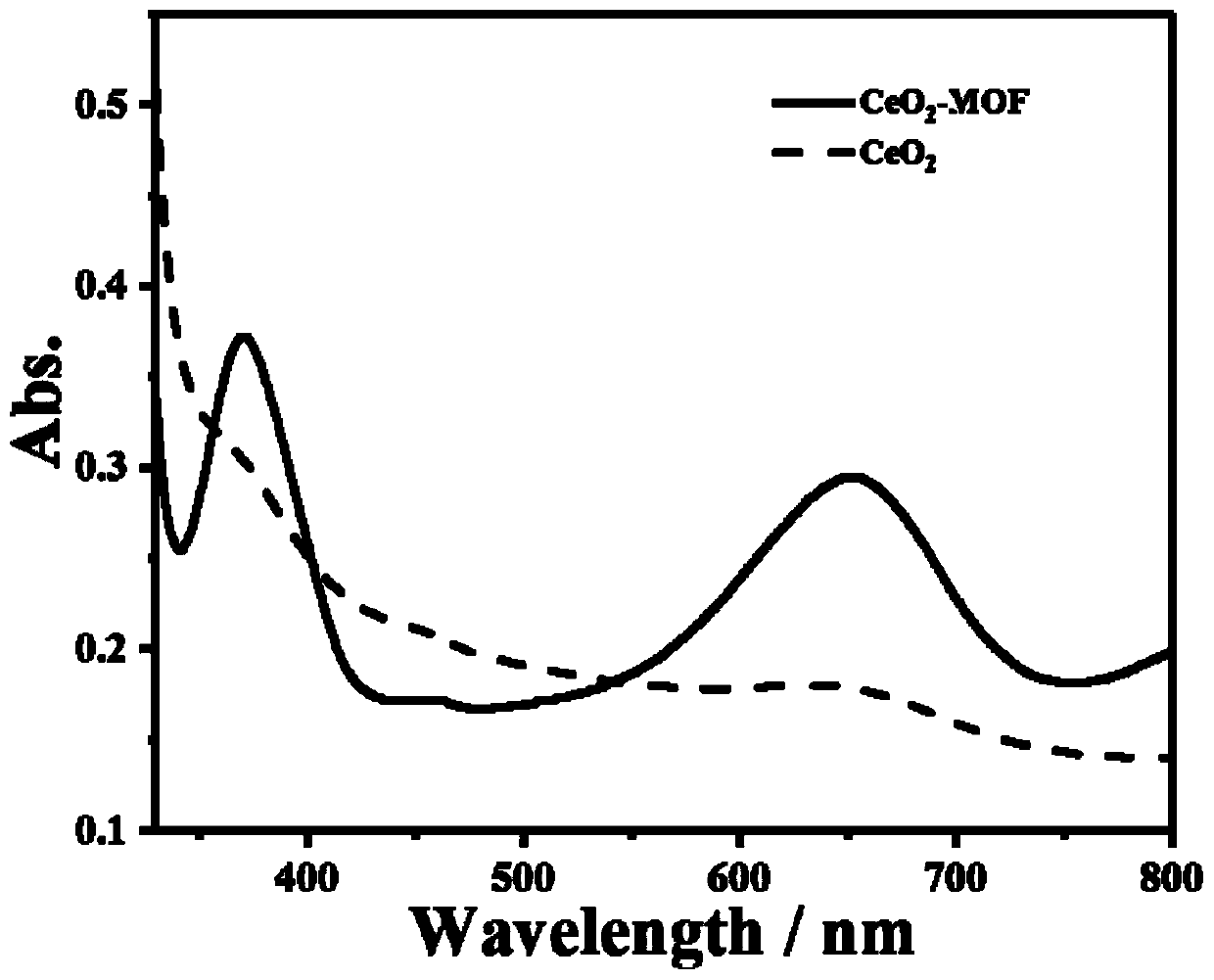

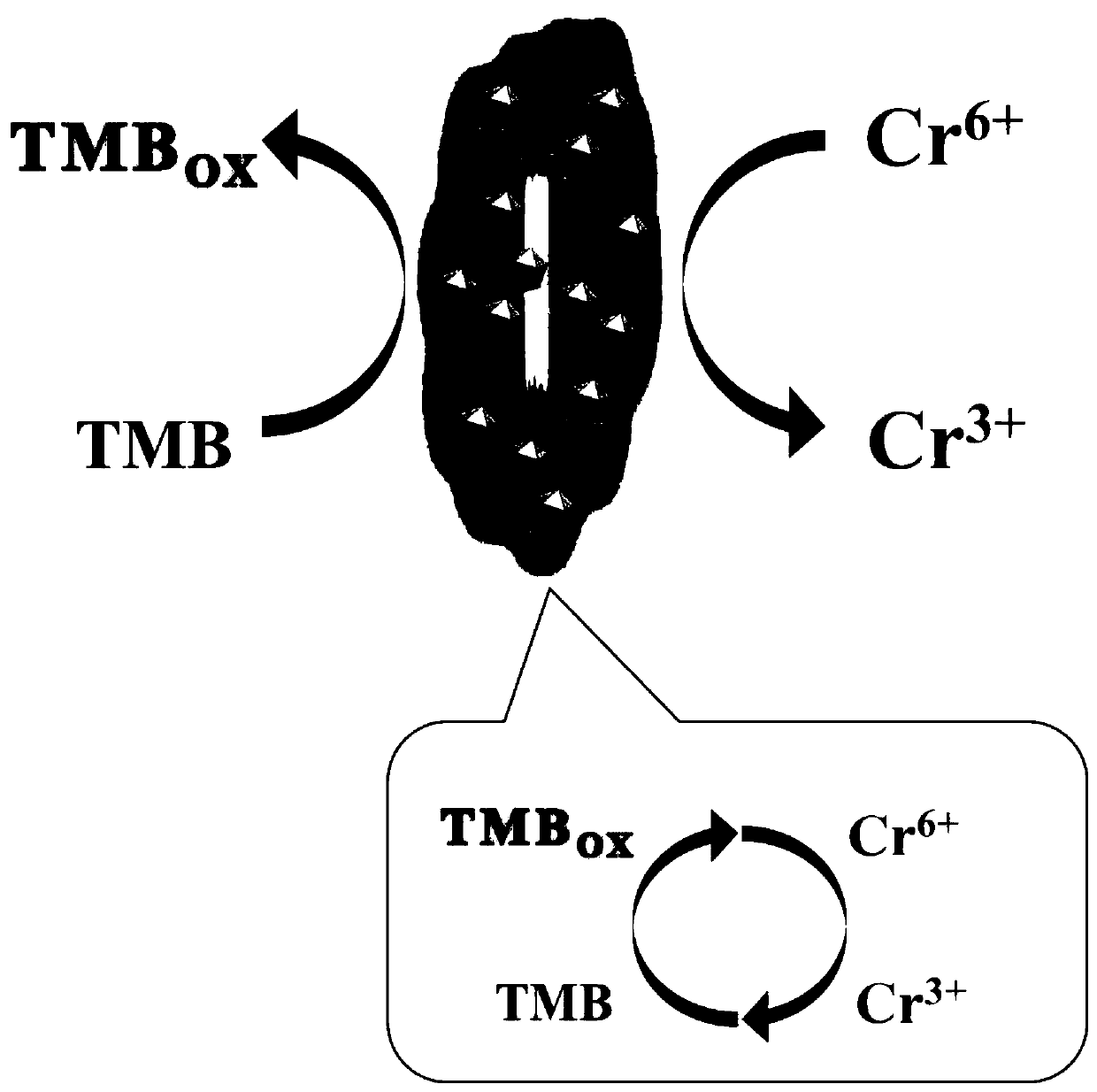

An organic framework and metal-based technology, which is applied in the field of optical sensing and achieves good application prospects, strong oxidase activity and good selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

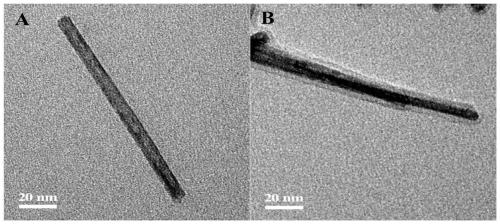

[0035] Example 1: Preparation of cerium-based metal-organic framework

[0036] Dissolve 0.434g of cerous nitrate hexahydrate and 4.8g of sodium hydroxide in 20mL of ultrapure water, stir and mix for 30 minutes, place the mixed solution in an autoclave at 100°C for 24 hours, and after cooling to room temperature, the product Wash with ultrapure water and ethanol for three times, and then place in a vacuum oven at 60°C overnight to obtain CeO 2 Nanorods; 20mg CeO 2 The nanorods were mixed with 30 mL of DMF solution containing 1.4952 g of terephthalic acid, and placed in an autoclave at 70 °C for 12 hours. After cooling to room temperature, the product was washed with DMF and ethanol for three times, and then placed at 60 °C overnight in a vacuum oven to obtain a cerium-based metal-organic framework (CeO 2 NRs-MOF).

Embodiment 2

[0037] Example 2: Preparation of cerium-based metal-organic framework

[0038] Dissolve 0.434g of cerous nitrate hexahydrate and 4.34g of sodium hydroxide in 20mL of ultrapure water, stir and mix for 20 minutes, place the mixed solution in an autoclave at 95°C for 20 hours, and after cooling to room temperature, the product Centrifugal washing with ultrapure water and ethanol twice in sequence, and then placed in a vacuum oven at 50 °C for 12 hours to obtain CeO 2 Nanorods; 20mg CeO 2 The nanorods were mixed with 30 mL of DMF solution containing 1.4 g of terephthalic acid, and placed in an autoclave at 65 °C for 10 hours. After cooling to room temperature, the product was centrifuged twice with DMF and ethanol, and then placed at 60 ℃ in a vacuum oven for 12 hours to obtain a cerium-based metal-organic framework (CeO 2 NRs-MOF).

Embodiment 3

[0039] Example 3: Preparation of cerium-based metal-organic framework

[0040] Dissolve 0.434g of cerous nitrate hexahydrate and 5.208g of sodium hydroxide in 20mL of ultrapure water, stir and mix for 40 minutes, place the mixed solution in an autoclave at 105°C for 30 hours, cool to room temperature, and prepare the product Centrifugal washing with ultrapure water and ethanol four times in turn, and then placed in a vacuum oven at 70 °C for 24 hours to obtain CeO 2 Nanorods; 20mg CeO 2 The nanorods were mixed with 30 mL of DMF solution containing 1.6 g of terephthalic acid, and placed in an autoclave at 75 °C for 15 hours. After cooling to room temperature, the product was centrifuged and washed four times with DMF and ethanol, and then placed at 70 °C. ℃ in a vacuum oven for 24 hours to obtain a cerium-based metal-organic framework (CeO 2 NRs-MOF).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com