Thick-film combination material chip high-throughput preparation method based on multisource plasma spraying and laser aftertreatment

A technology of combining material chips and plasma, applied in metal material coating process, coating, melting spray plating, etc., can solve the problems of long cycle and high cost, and achieve exponential speed increase, cost reduction, and rapid and continuous preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

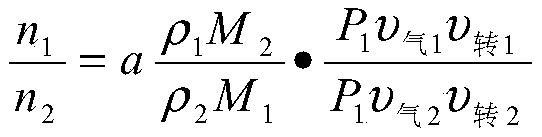

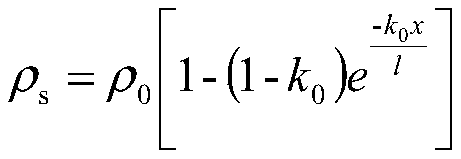

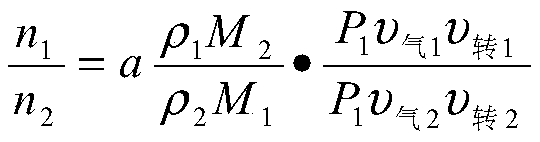

Method used

Image

Examples

Embodiment 1

[0034] A method for high-throughput preparation of thick-film composite material chips based on multi-source plasma spraying and laser post-treatment, comprising the following steps:

[0035] (1) Pre-preparing composite material chips whose composition changes continuously along the direction of the substrate surface with multi-station plasma spraying equipment:

[0036] 1a. Select the pure metal powder of the component elements of the combined material chip to be prepared; select the base material of the combined material chip; wherein, the base material of the combined material chip is a pure metal plate having the same main component elements as the combined material chip;

[0037] 1b. Sandblasting the surface of the base material, cleaning the base material with acetone solution and ethanol solution, and then putting it into a drying oven to dry; wherein, the drying temperature is 160-200°C, and the drying time is 1.5-2.5h;

[0038] 1c. Pour the pure metal powder into the ...

Embodiment 2

[0054] A method for high-throughput preparation of thick-film composite material chips based on multi-source plasma spraying and laser post-treatment, comprising the following steps:

[0055] (1) Pre-preparing composite material chips whose composition changes continuously along the direction of the substrate surface with multi-station plasma spraying equipment:

[0056] 1a. Select the pure metal powder of the component elements of the combined material chip to be prepared. If the high-energy wear-resistant NiAl material is screened, then select pure nickel powder with a purity higher than 99.99%, and pure aluminum powder with a purity higher than 99.99%; select the combined material chip Substrate, which requires a pure metal plate with the same main constituent elements as the chip;

[0057] 1b. Sandblast the surface of the substrate, wash the substrate with acetone solution and ethanol solution, and then put it in a drying oven to dry; wherein, the drying temperature is 180...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com