Lithium titanate/titanium dioxide nanocomposite particle with controllable composition, preparation method and application thereof

A titanium dioxide and nano-composite technology, which is applied in the direction of secondary batteries, electrochemical generators, structural parts, etc., can solve problems such as short circuit, explosion, and combustion, and achieve increased specific capacity, improved specific capacity and rate performance, and good ion The effect of transmission diffusion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

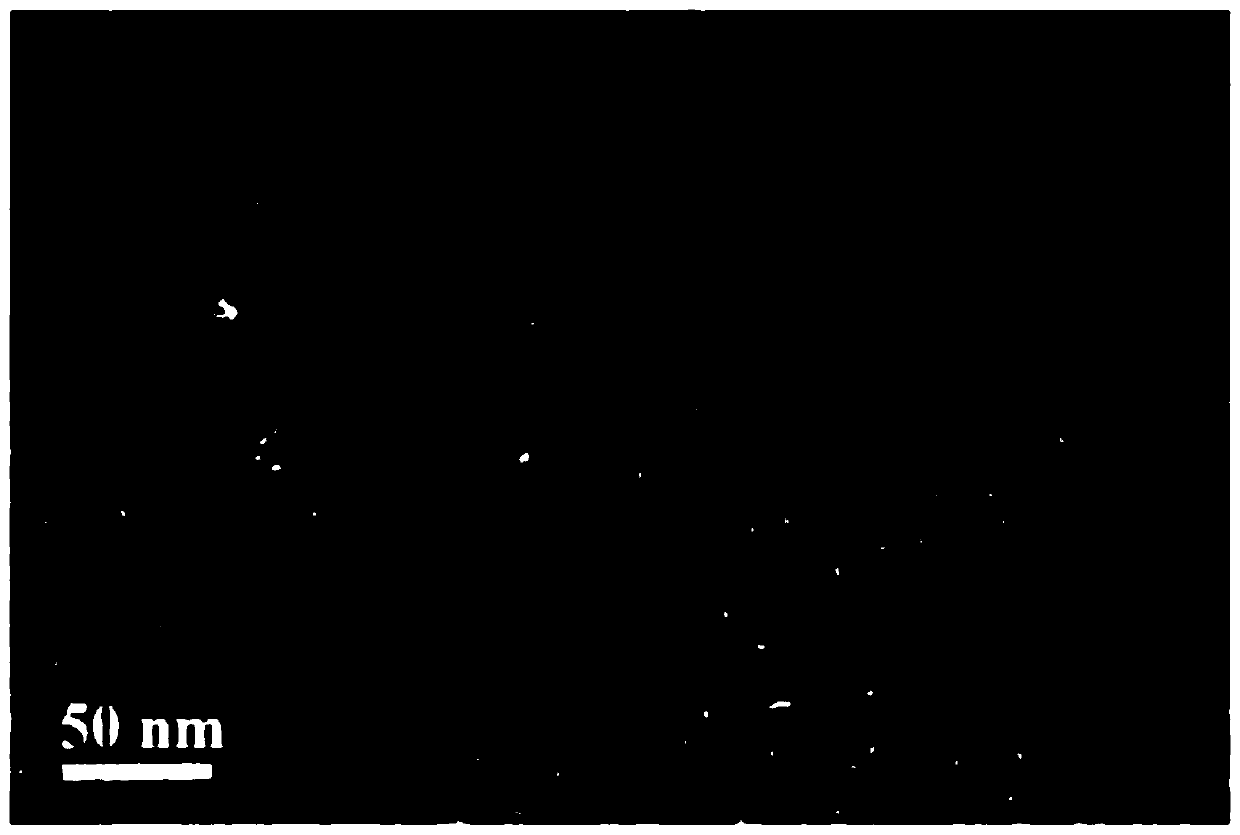

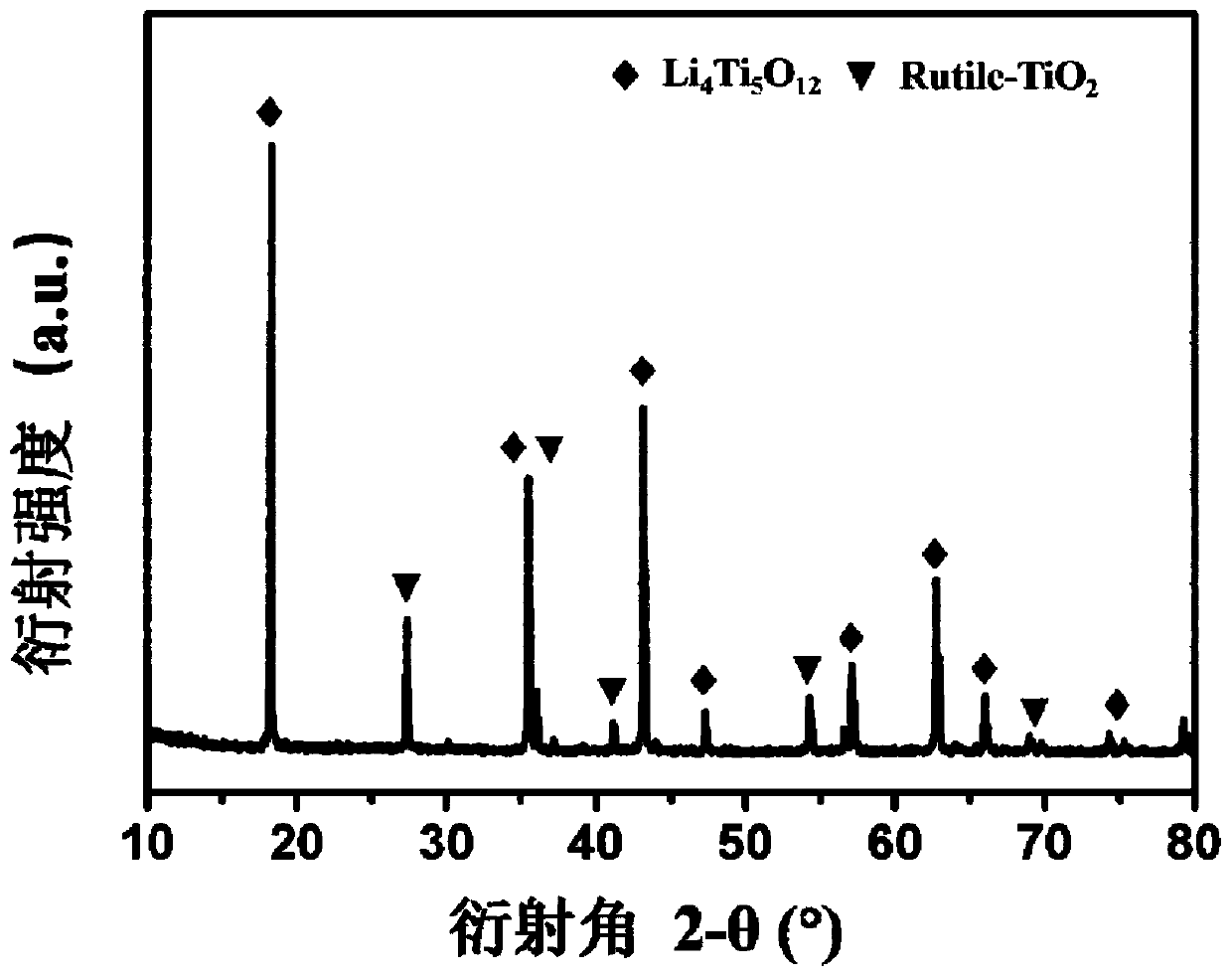

[0030] (1) Preparation of precursor solution: Weigh 0.02mol lithium nitrate and dissolve it in 30ml ethanol, then add 0.03mol tetrabutyl titanate, then add 70ml xylene, lithium source in the system: titanium source=4:6( Mass ratio), after mixing, sonicate for 15 minutes to obtain a precursor solution, which is ready for use;

[0031] (2) Use a peristaltic injection pump to feed the precursor solution at a certain feed rate of 5ml / min to form fine atomized droplets through the atomization burner and send them into the spray combustion reactor with a shear pressure of 0.1MPa. in H 2 / O 2 (H 2 Flow 0.15m 3 / h,O 2 Flow 1m 3 / h) A series of reactions of combustion, pyrolysis, and oxidation occur under the assistance of a diffusion flame. After the flame is burned, the particles pass through a vacuum pump and are deposited on the glass fiber filter membrane of the collector to obtain a lithium titanate / titanium dioxide nanocomposite particle precursor;

[0032] (3) Calcining t...

Embodiment 2

[0034] (1) Preparation of precursor solution: Weigh 0.02mol lithium nitrate and dissolve it in 30ml ethanol, then add 0.03mol tetrabutyl titanate, then add 70ml xylene, lithium source in the system: titanium source=4:6( Mass ratio), after mixing, sonicate for 15 minutes to obtain a precursor solution, which is ready for use;

[0035](2) Use a peristaltic syringe pump to feed the precursor solution at a certain feed rate of 5ml / min to form fine atomized droplets through the atomization burner and send them into the spray combustion reactor. The shear pressure is 0.08MPa, and the atomized droplets in H 2 / O 2 (H 2 Flow 0.1m 3 / h,O 2 Flow 1m 3 / h) A series of reactions of combustion, pyrolysis, and oxidation occur under the assistance of a diffusion flame. After the flame is burned, the particles pass through a vacuum pump and are deposited on the glass fiber filter membrane of the collector to obtain a lithium titanate / titanium dioxide nanocomposite particle precursor;

[...

Embodiment 3

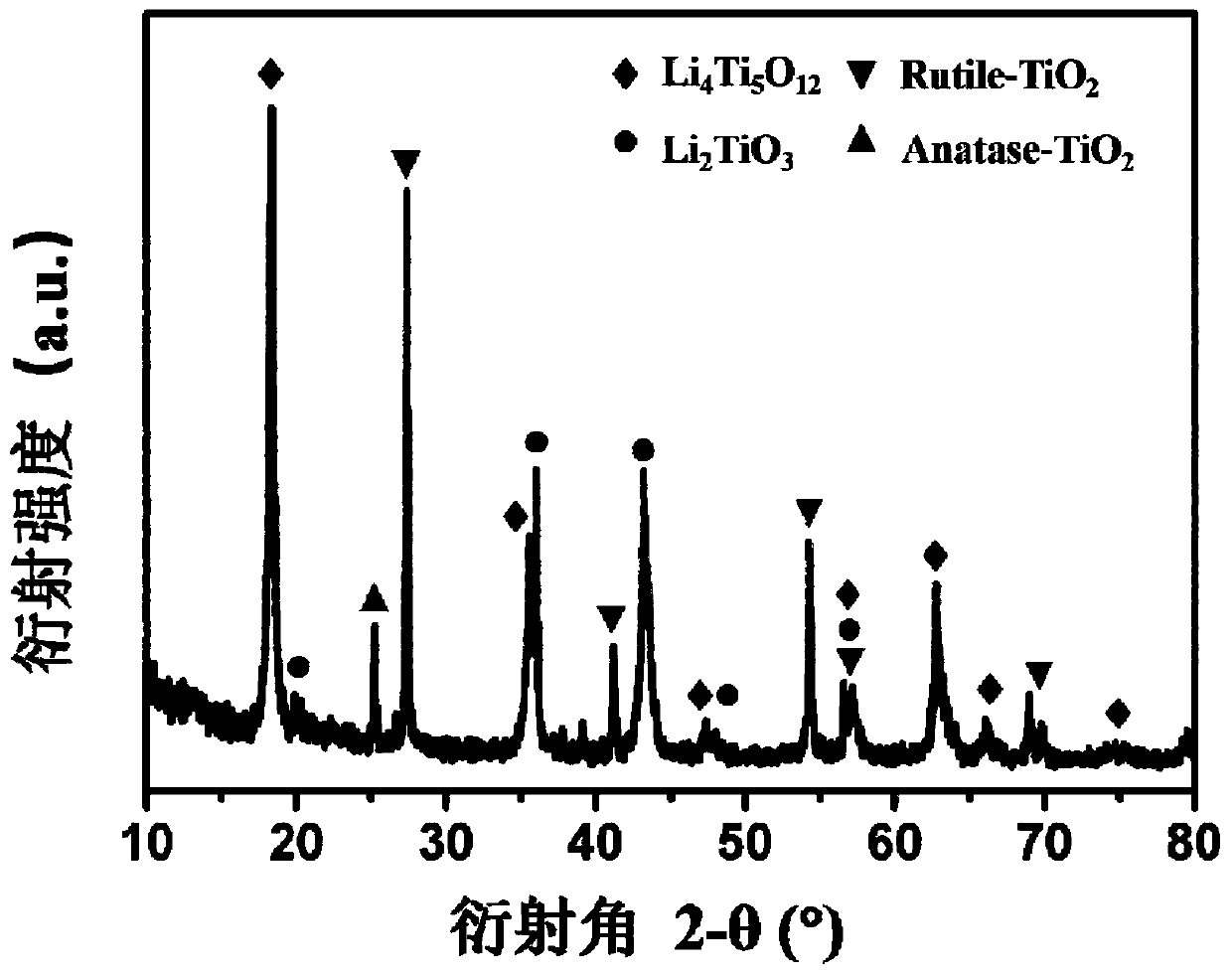

[0038] (1) Preparation of precursor solution: Weigh 0.03mol lithium nitrate and dissolve it in 30ml ethanol, then add 0.02mol tetrabutyl titanate, then add 70ml xylene, lithium source in the system: titanium source = 6:4( Mass ratio), after mixing, sonicate for 20 minutes to obtain a precursor solution, which is ready for use;

[0039] (2) Use a peristaltic injection pump to feed the precursor solution at a certain feed rate of 6ml / min to form fine atomized droplets through the atomization burner and send them into the spray combustion reactor. The shear pressure is 0.12MPa, and the atomized droplets in H 2 / O 2 (H 2 Flow 0.1m 3 / h,O 2 Flow 1m 3 / h) A series of reactions of combustion, pyrolysis, and oxidation occur under the assistance of a diffusion flame. After the flame is burned, the particles pass through a vacuum pump and are deposited on the glass fiber filter membrane of the collector to obtain a lithium titanate / titanium dioxide nanocomposite particle precursor;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com