Sound insulation plate-frame integrated floor plate structure and production method thereof

A production method and technology for floor panels, which are applied in the directions of sound insulation, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of inability to assemble large buildings, poor heat resistance, etc., and achieve easy aging and decomposition. Good, sound insulation performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

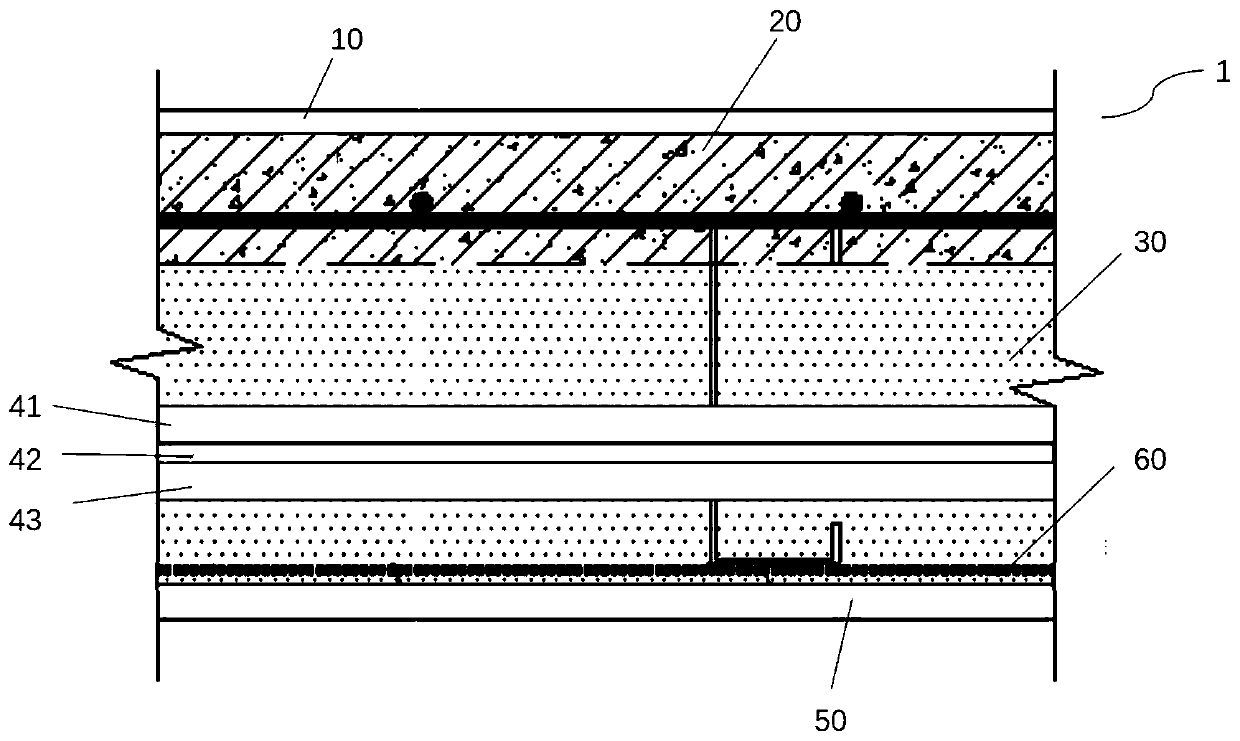

[0074] figure 1 Structural drawing of an exemplary sound insulation board frame combined with a floor slab. Such as figure 1 As shown, the sound-insulating board-frame-integrated floor 1 of this embodiment sequentially includes a decorative layer 10, a fine stone concrete layer 20, a foamed cement layer 30, a first building board 41, a polymer damping material 42, a second building board 43 and Cement mortar protective layer 50. Wherein, the thickness of the decorative layer 10 is generally 5-15mm, and the decorative layer 10 can be a ceramic tile layer or a real stone paint layer and the like. The thickness of the fine stone concrete layer 20 is 30-50mm, and it can be a layer composed of C30 fine stone concrete. The thickness of the foamed cement layer 30 is generally 100-140mm, and its bulk density can be 450-550kg / m 3 . This type of foamed cement layer 30 can not only greatly reduce the overall weight of the floor slab, but also enhance thermal insulation and sound ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com