A silicon wafer drying machine

A drying machine, silicon wafer technology, applied in dryers, non-progressive dryers, drying, etc., can solve the problems of poor cleaning effect on the surface of silicon wafers, and achieve strong structural replaceability and strong practicability , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

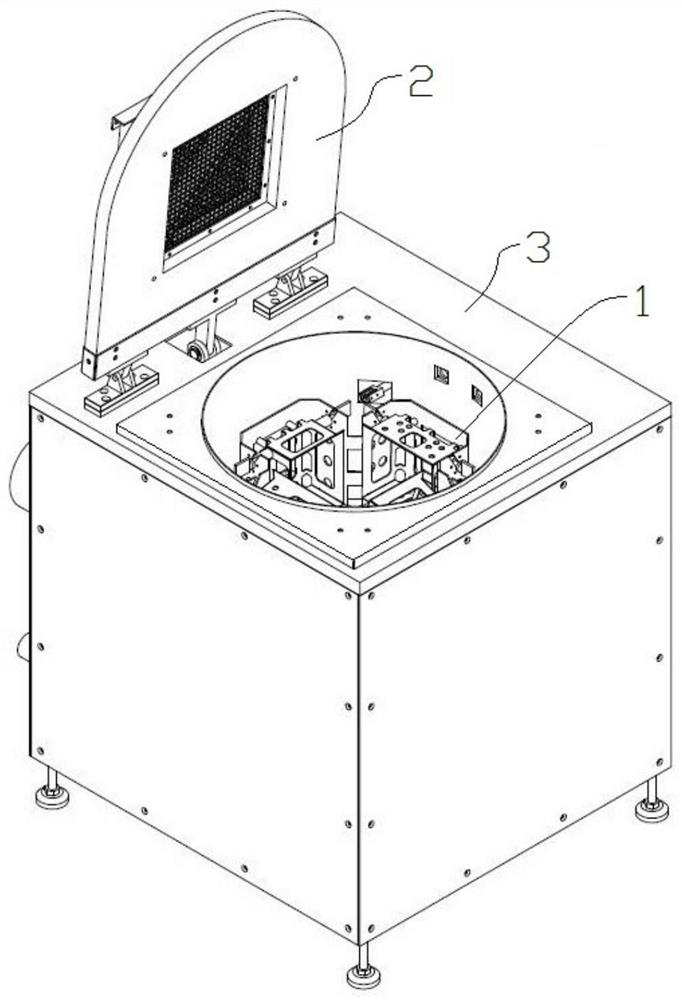

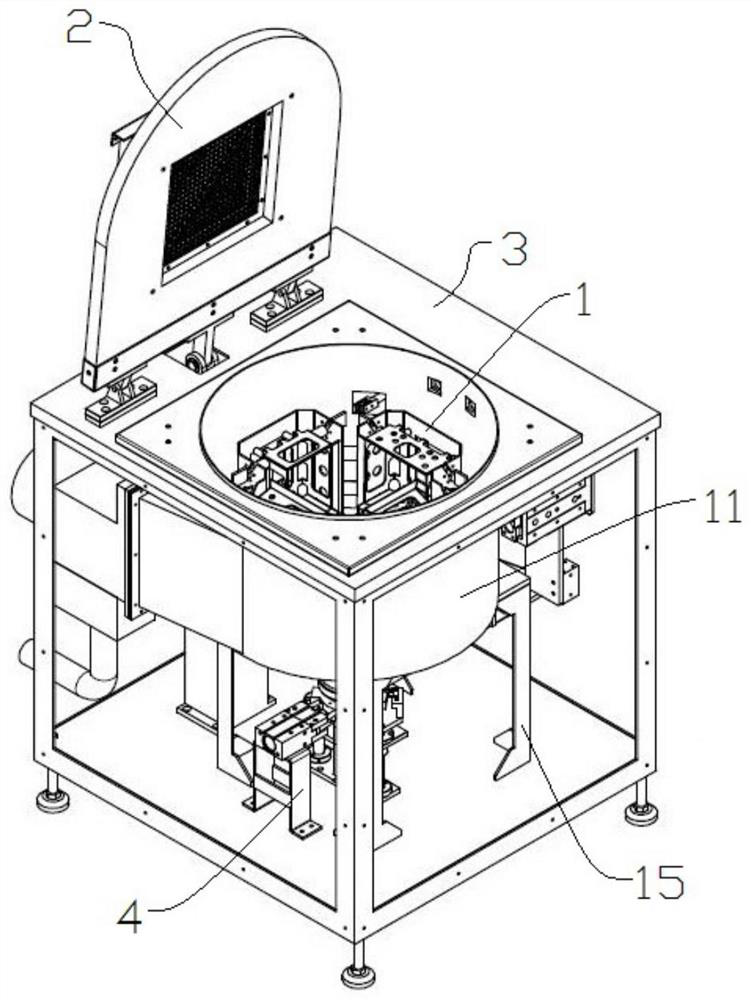

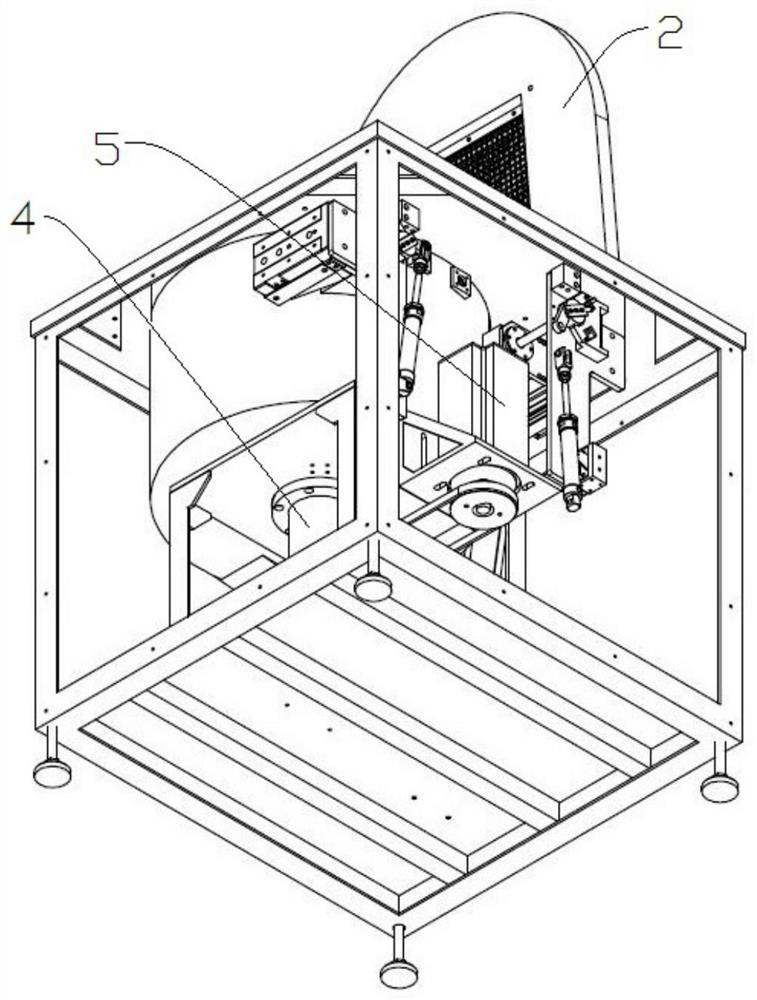

[0039] see Figure 1-3 , this embodiment proposes a silicon wafer drying machine, including a centrifugal drying assembly 1 , a sealing cover 2 and a frame 3 .

[0040] Specifically, as Figure 5 , 6 As shown, the centrifugal drying assembly 1 includes a drying barrel 11, a centrifugal basket 12, a drying box (13, 14), a fixing frame 15 and a centrifugal power assembly, and the drying barrel is provided with a cylindrical wall, including The 4-inch drying box 13 and the 6-inch drying box 14 are provided with an adjustment hole 113 of a lifting mechanism on the periphery, a sensor 114 is arranged between two adjacent adjustment holes 113, and a dehydration pipe 112 and a drain pipe are arranged tangentially on the inner side of the cylinder wall. Pressure tube 115, the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com