Method for detecting low-concentration benzene dynamic adsorption value of activated carbon fiber

A technology of activated carbon fiber and dynamic adsorption, which is applied in the detection field, can solve the problems of poor knowledge of adsorption performance, time-consuming and high-toxicity risks of benzene, etc., and achieve the effect of reducing experimental safety risks, reducing labor costs, and reducing exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

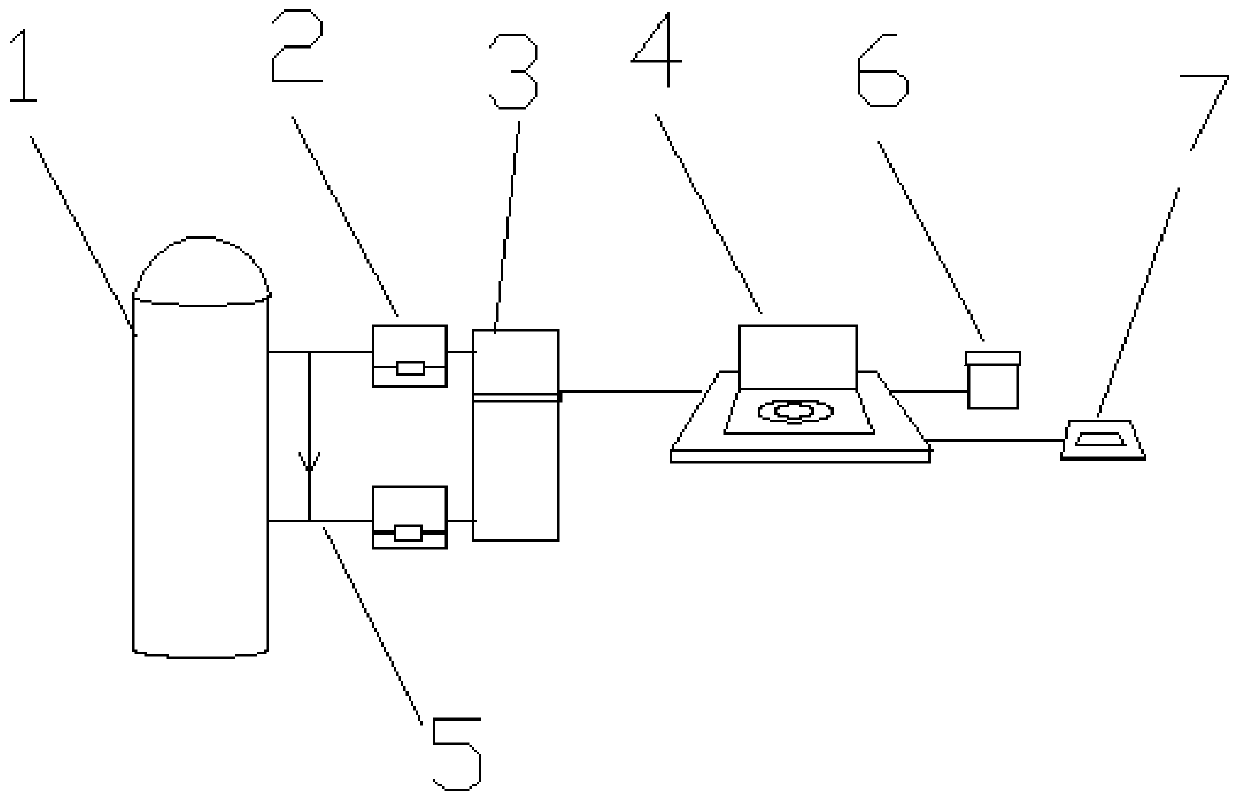

[0027] Embodiment 1: first put the activated carbon fiber after drying into the steam generation mixing device 3, the nitrogen container 1 is connected to the gas flow meter 2, and the gas flow meter 2 is connected to the steam generation mixing container 3, and is connected to the device through the conduit 5. In the dynamic adsorption device 4, the dynamic adsorption device 4 is connected to the exhaust gas recovery container 6, and finally the change of the quality of the activated carbon fiber is measured by the computer 7. After the set adsorption time is reached, the introduction of the nitrogen container 1 is closed, and the mass data recording is ended.

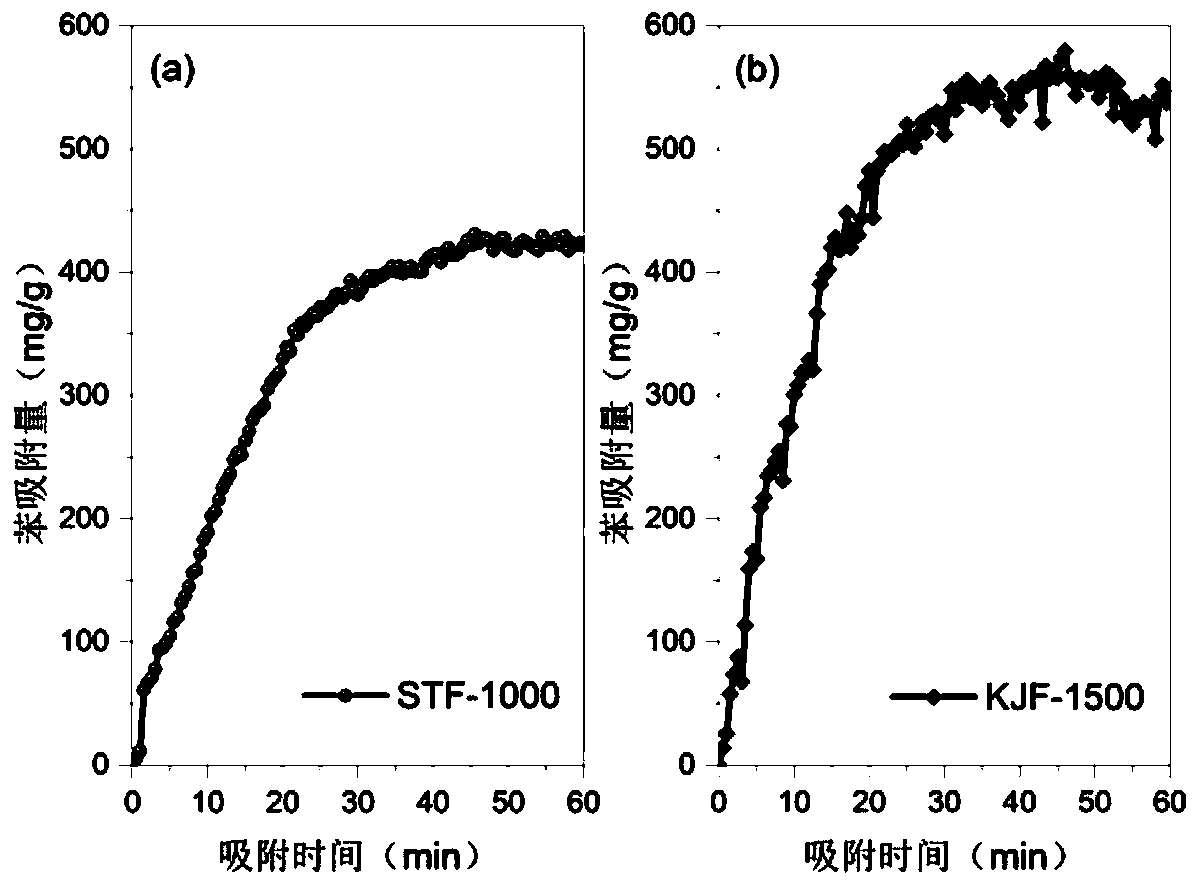

[0028] Two specifications of viscose-based activated carbon fibers STF-1000 and KJF-1500 were selected, and 5 g of each was boiled in 1 L of distilled water for 2 h. After taking out, they were fully rinsed with distilled water, and dried in an oven at 105 °C for later use.

[0029] At room temperature, according to t...

Embodiment 2

[0034] The determination of embodiment 2 adsorbent ACF consumption:

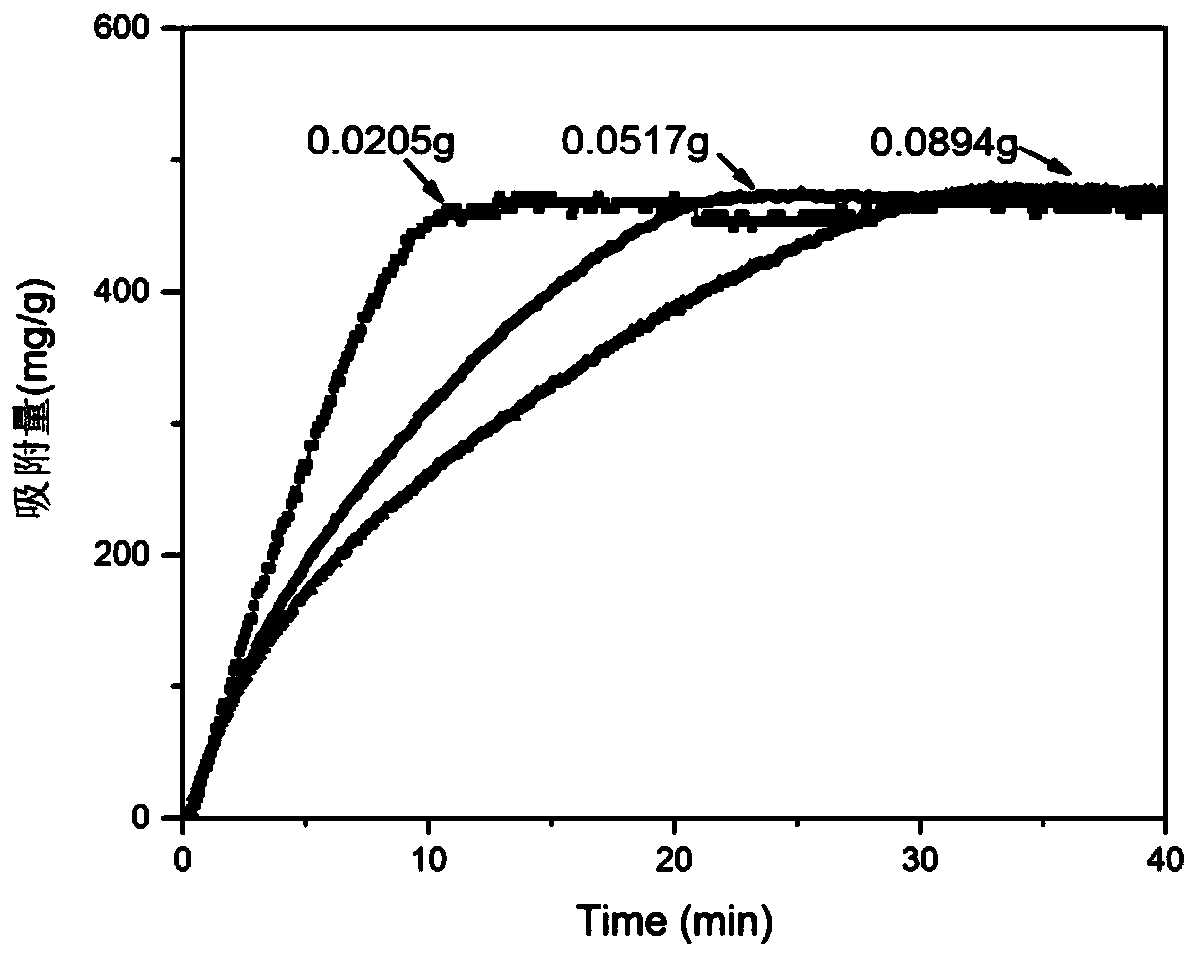

[0035] For the same ACF, ACF with different masses were weighed as 0.0205g, 0.0517g, and 0.0894g, respectively. The 3 samples were subjected to the dynamic benzene adsorption test according to the method respectively, and the test results were as follows: image 3 shown.

[0036] Depend on image 3 It can be seen that although the amount of adsorbent used in the test is different for the same activated carbon fiber, the adsorption amount after adsorption equilibrium is basically the same, indicating that the dynamic benzene adsorption value of the same sample is basically the same under the test results of this method. Comparing the differences among the three, there are differences mainly in the time point when they tend to balance. When the amount of activated carbon fiber tested is small, the time for the adsorption to reach equilibrium is short, about 10 minutes; and when the quality is high, the equi...

Embodiment 3

[0037] The determination of embodiment 3 adsorption time:

[0038] 5 pieces of ACF samples, the sampling volume of ACF1~5 is about 0.05g respectively, the measured dynamic adsorption curve of benzene is as follows Figure 4 shown. It can be found that the equilibration time of different ACF samples is different as marked by the dotted line. For the versatility of the experimental method, the single experiment time should ensure the adsorption equilibrium, therefore, the adsorption time was set to 60 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com