Self-diagnosis method and system for numerical control machine

A technology of self-diagnosis system and CNC machine tool, which is applied in general control system, control/adjustment system, program control, etc. It can solve the problem that the specific cause of product failure cannot be obtained, and achieve the effect of convenient maintenance and improved detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

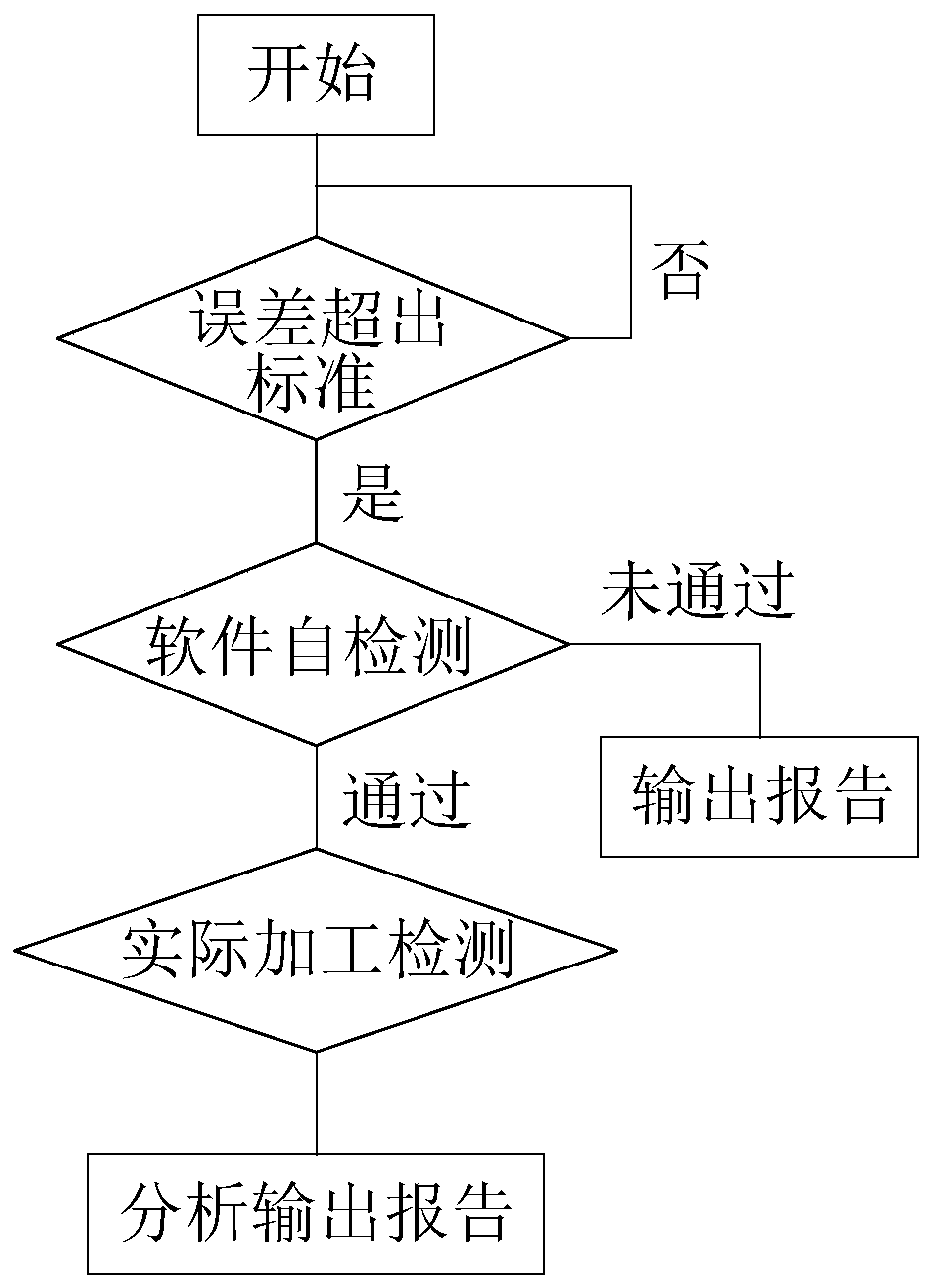

[0040] A kind of numerical control machine tool self-diagnosis method, refer to figure 1 , including step S101 to step S102.

[0041] Step S101: When the error exceeds the standard, first run the software self-test, including the system simulation operation with the same process and parameters, test whether the total error meets the standard, and decompose the processing process, and simulate each step through the system to test whether the error of the step meets the standard. standard.

[0042] The error in step S101 exceeds the standard, which refers to the error compared with the standard size after the workpiece is processed. For the specific detection of the workpiece, refer to the invention patent with application number 201410605568.6. Software self-inspection means that the controller of the lathe runs the simulation inspection software, and runs the program simulation processing with the same parameters and the same process without load. Finally, compare the total ...

Embodiment 2

[0049] A self-diagnosis system for CNC machine tools, referring to figure 2 , including a processor 1 and a memory 2, the memory 2 stores an instruction set for the processor 1 to call to realize the following functions:

[0050] When the error exceeds the standard, first run the software self-test, including the system simulation operation with the same process and parameters, test whether the total error meets the standard, and decompose the processing process, and simulate each step through the system to test whether the error of the step meets the standard;

[0051] After the software self-inspection is passed, the actual processing inspection is carried out, including the actual processing with the same process and parameters, and the error after each processing step is detected during the processing process, and compared with the standard error of each step, and decomposed The two processing steps before and after are processed separately, and the total error of detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com