Multi-mode ultrasonic motor driving control system

An ultrasonic motor and drive control technology, which is applied to generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Consistency and output characteristics, the effect of speeding up the solution process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but it is not limited thereto. Any modification or equivalent replacement of the technical solution of the present invention without departing from the spirit and scope of the technical solution of the present invention should be covered by the present invention. within the scope of protection.

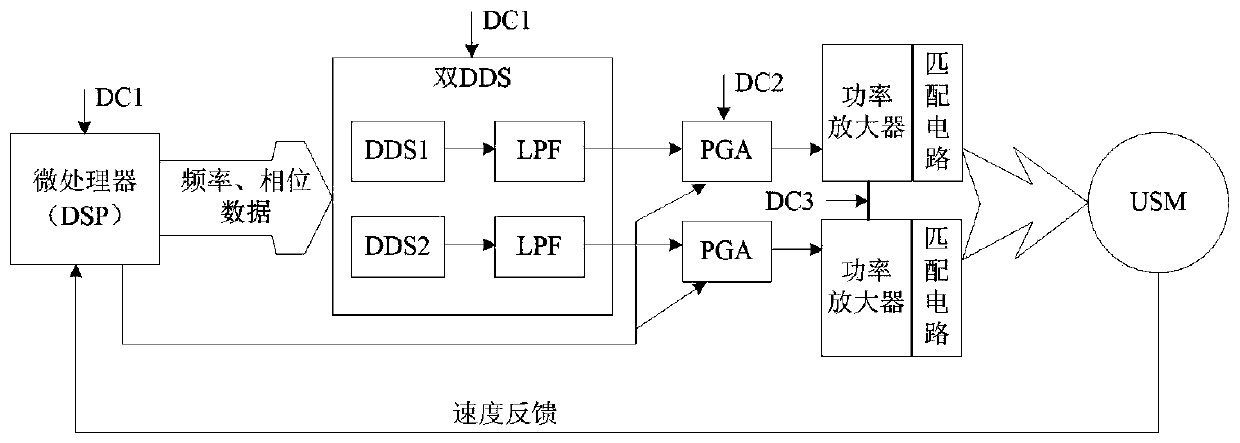

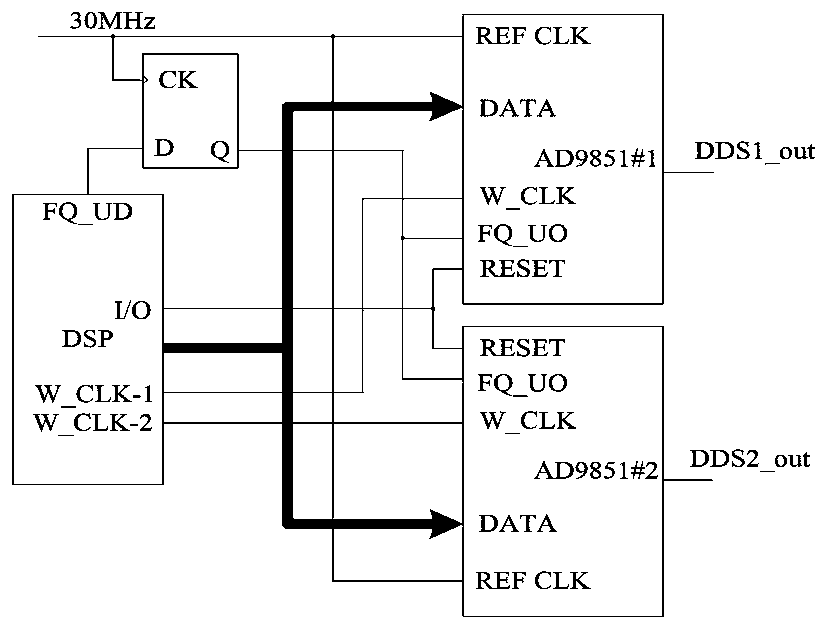

[0039] The present invention takes longitudinal bending mode conversion type traveling wave ultrasonic motor as the research object, and designs a multi-mode ultrasonic motor drive control system, which specifically includes the following contents:

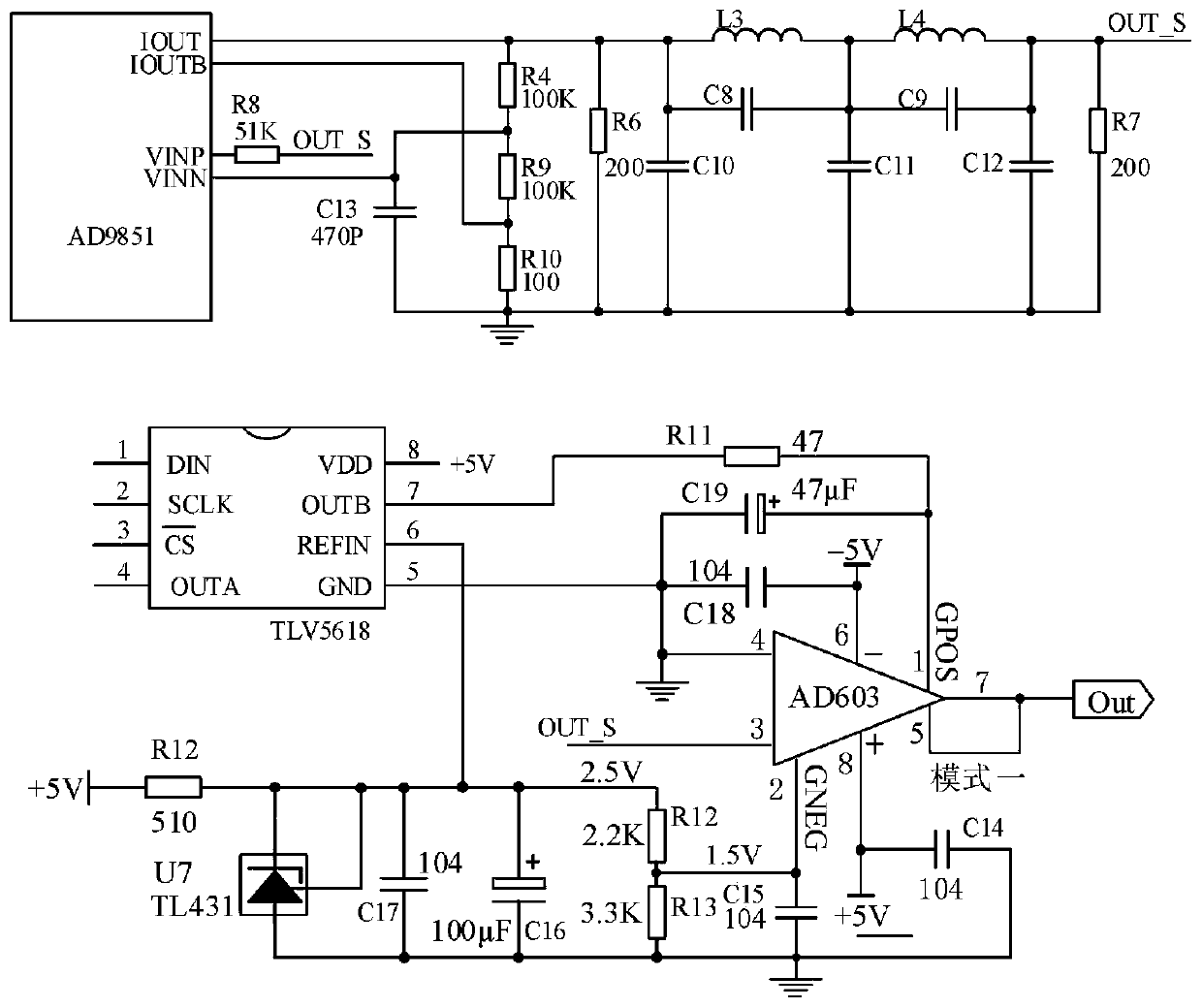

[0040] 1. Hardware design of ultrasonic motor driver

[0041] (1) Principle design of ultrasonic motor driver

[0042] The controller of the present invention adopts single-variable frequency modulation and speed regulation to control, that is, the phase is fixed at 90° or -90° according to the requirement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com