Screening method of silicon-calcium collophanite ore

A collophosite and screening technology, applied in chemical instruments and methods, solid separation, wet separation, etc., can solve problems affecting the normal operation of chemical production equipment, flotation foam is easy to stick, and product utilization rate is low. Achieve the effect of saving investment cost, improving utilization rate and low procurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

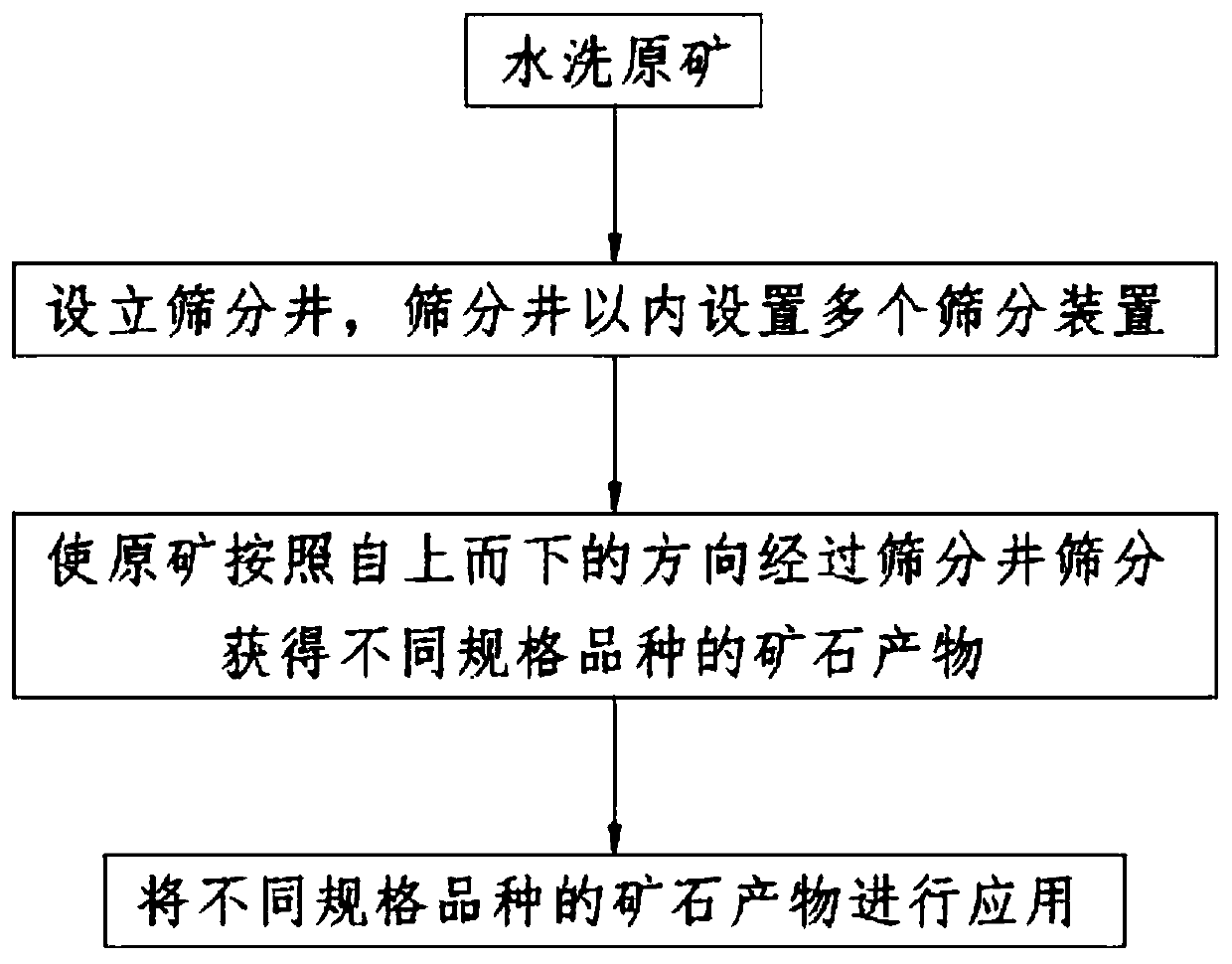

[0020] Such as figure 1 Shown, the invention provides a kind of screening method of siliceous-calcic colloidal phosphate rock, comprises the following steps:

[0021] Step 1: Wash the raw ore with water: obtain the raw ore through mining, use water to scrub the raw ore, and remove the soil attached to the surface of the raw ore;

[0022] Step 2: Set up a screening well at the screening site, and install a primary screening device, a secondary screening device, and a tertiary screening device in the screening well in sequence from top to bottom. The primary screening device, the secondary screening device and the tertiary screening device are respectively provided with a screening hole A, a screening hole B and a screening hole C, and the screening hole A, the screening hole B and the screening hole C. The pore size decreases succ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com