Reagent and method for restoring mercury-polluted soil by using modified activated carbon

A technology of activated carbon and mercury pollution, applied in the restoration of polluted soil, soil conditioning materials, chemical instruments and methods, etc., can solve problems such as poor effect, environmental impact, secondary soil pollution, etc. Easy availability of materials and the effect of improving soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

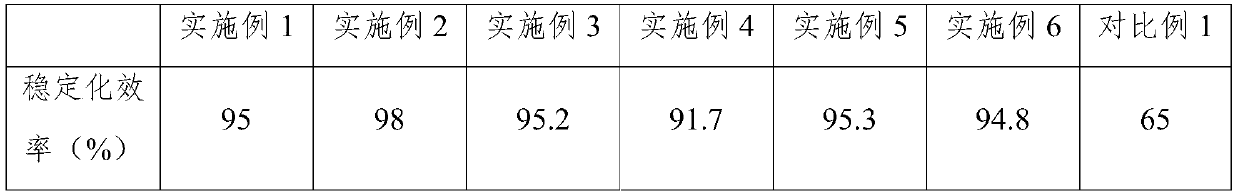

Examples

Embodiment 1

[0028] S1. Weigh 10g of activated carbon powder and place it in a 250mL conical flask, add KMnO with a concentration of 0.03mol / L according to the solid-to-liquid ratio of 1:5g / mL 4 solution, sealed. Place in a constant temperature shaking box for shaking reaction. Adjust the condition of the constant temperature shaking box to 25°C, 200±10r / min, and shake for 12h.

[0029] S2. Wash the activated carbon after the shaking reaction in S1 above to neutrality with deionized water, put it into an oven at 100°C for drying, and grind it for later use to obtain oxidatively modified activated carbon.

[0030] S3. Measure 35 mL of ethanol and 2.5 mL of water into a 250 mL Erlenmeyer flask, slowly add 5.5 mL of trimercaptopropyltrimethoxysilane, and let stand for half an hour. Take 10g of the above-mentioned oxidation-modified activated carbon in S2, stir it into the Erlenmeyer flask, seal it, adjust the condition of the constant temperature shaking box to 25°C, 110±10r / min, and shake ...

Embodiment 2

[0039] S1. Weigh 10g of activated carbon powder and place it in a 250mL conical flask, add KMnO with a concentration of 0.03mol / L according to the solid-to-liquid ratio of 1:5g / mL 4 Solution, sealed; placed in a constant temperature shaking box for shaking reaction. Adjust the condition of the constant temperature shaking box to 25°C, 200±10r / min, and shake for 12h.

[0040] S2. The activated carbon shaken in S1 above was washed with deionized water until neutral, dried in an oven at 105° C., ground for later use, and oxidized modified activated carbon was obtained.

[0041] S3. Measure 70 mL of ethanol and 5 mL of water into a 250 mL Erlenmeyer flask, slowly add 11 mL of trimercaptopropyltrimethoxysilane, and let stand for half an hour. Take 10g of the above-mentioned oxidation-modified activated carbon in S2, stir it into the Erlenmeyer flask, seal it, adjust the condition of the constant temperature shaking box to 25°C, 110±10r / min, and shake it for 6h.

[0042] S4. Wash ...

Embodiment 3

[0045] S1. Weigh 10g of activated carbon powder and place it in a 250mL conical flask, add KMnO with a concentration of 0.03mol / L according to the solid-to-liquid ratio of 1:5g / mL 4 solution, sealed. Place in a constant temperature shaking box for shaking reaction. Adjust the condition of the constant temperature shaking box to 25°C, 200±10r / min, and shake for 12h.

[0046]S2. The activated carbon shaken in S1 above was washed with deionized water until neutral, dried in an oven at 100°C, and ground for later use to obtain oxidatively modified activated carbon.

[0047] S3. Measure 70 mL of ethanol and 5 mL of water into a 250 mL Erlenmeyer flask, slowly add 11 mL of trimercaptopropyltrimethoxysilane, and let stand for half an hour. Take 5g of the above-mentioned oxidation-modified activated carbon in S2, stir it into the Erlenmeyer flask, seal it, adjust the condition of the constant temperature shaking box to 25°C, 110±10r / min, and stir for 6h.

[0048] S4. Wash the modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com