A kind of preparation method of ternary composite inorganic gelling material of current exhaust furnace slag

An inorganic cementitious material and ternary composite technology, applied in cement production, etc., to achieve good volume stability, reduce environmental pressure, and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

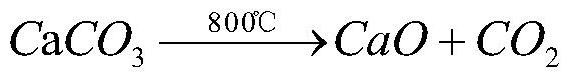

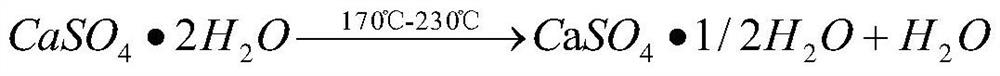

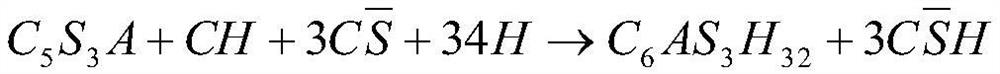

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]A method for preparing a ternary composite inorganic gelling material for existing slag, comprising the following steps:

[0037] 1) Mix and stir the currently discharged slag and limestone fine powder until the temperature of the material drops to 400°C, and record it as powder A, wherein the mass ratio of slag to limestone fine powder is 100:10.

[0038] 2) Add phosphogypsum to powder A, mix and stir until the temperature drops to 40°C, and record it as powder B, where the mass ratio of powder A to phosphogypsum is 100:15.

[0039] 3) The powder B is mechanically ground until the maximum particle size is less than 45 μm to obtain the inorganic gelling material.

[0040] After testing, the 3d compressive strength of the inorganic gelling material prepared in this example is 6 MPa, and the 56d compressive strength is 36 MPa.

Embodiment 2

[0042] A method for preparing a ternary composite inorganic high-performance cementitious material for existing slag, comprising the following steps:

[0043] 1) Mix and stir the currently discharged slag and limestone fine powder until the temperature of the material drops to 400°C, and record it as powder A, wherein the mass ratio of slag to limestone fine powder is 100:25.

[0044] 2) Add phosphogypsum to powder A, mix and stir until the temperature drops to 55°C, and record it as powder B, where the mass ratio of powder A to phosphogypsum is 100:15.

[0045] 3) The powder B is mechanically ground until the maximum particle size is less than 45 μm to obtain the inorganic gelling material.

[0046] After testing, the 3d compressive strength of the inorganic gelling material prepared in this example is 10 MPa, and the 56d compressive strength is 40 MPa.

Embodiment 3

[0048] A method for preparing a ternary composite inorganic high-performance cementitious material for existing slag, comprising the following steps:

[0049] 1) Mix and stir the currently discharged slag and limestone fine powder until the temperature of the material drops to 500°C, and record it as powder A, wherein the mass ratio of slag to limestone fine powder is 100:18.

[0050] 2) Add phosphogypsum to powder A, mix and stir until the temperature drops to 65°C, and record it as powder B, where the mass ratio of powder A to phosphogypsum is 100:35.

[0051] 3) The powder B is mechanically ground until the maximum particle size is less than 45 μm to obtain the inorganic gelling material.

[0052] After testing, the 3d compressive strength of the inorganic gelling material prepared in this example is 12 MPa, and the 56d compressive strength is 45 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com