External-application waterproofing filler for communication cable insulating layer and preparation method for external-application waterproofing filler

A technology for communication cables and insulation layers, which is applied in the field of water-blocking fillers for external communication cable insulation layers and its preparation, can solve the problems of affecting the stability of the insulation layer, affecting the service life of cables, and the general water-blocking effect, so as to improve the strain performance and Self-healing ability, shorten cooling time, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

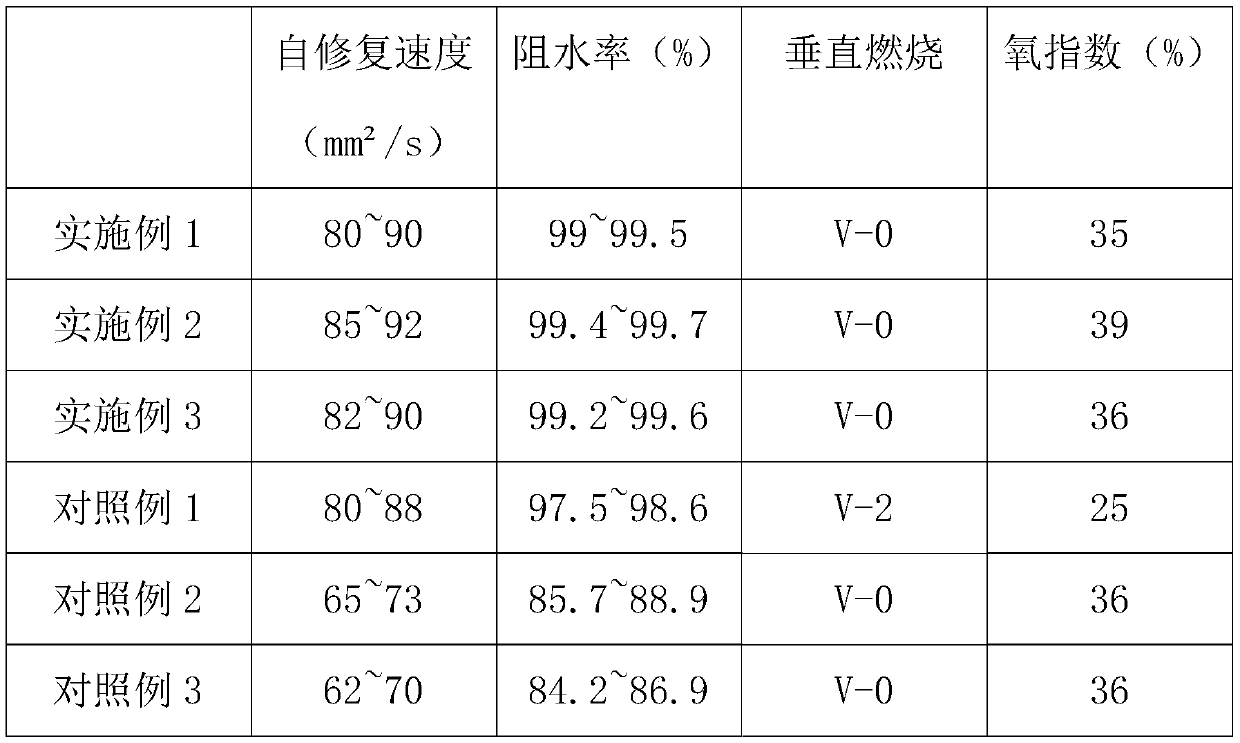

Examples

Embodiment 1

[0020] 1) Weighing according to the formula, 10 parts of modified cyclodextrin solution, 4 parts of polystyrene, 6 parts of polyalphaolefin, 1 part of calcium carbonate, 0.4 part of stannous octoate, 0.1 part of maleic acid, Put 4 parts of 1,4-butanediol and 4 parts of carbon black into the reaction kettle, mix and stir evenly, heat up to 60 degrees Celsius, and react for 20 minutes;

[0021] 2) Continue to add 10 parts of methanol and 0.4 parts of aluminum foam when the temperature is 80 degrees Celsius, and mix and react for 20 minutes;

[0022] 3) Put the mixture obtained in step 2) into an internal mixer for mixing. The mixing temperature is 130° C., and the mixing time is 30 minutes. After the mixed material is discharged, it is dried, and the drying temperature is 100° C. , the drying time is 12h, the dried material passes through the water cooling tank, the water flow rate is 1m / s, and the water-blocking filler is obtained, and the particle size of the water-blocking fi...

Embodiment 2

[0025] 1) Weighing according to the formula, 20 parts of modified cyclodextrin solution, 6 parts of polystyrene, 8 parts of polyalphaolefin, 2 parts of calcium carbonate, 0.5 part of stannous octoate, 0.2 part of maleic acid, Put 7 parts of 1,4-butanediol and 5 parts of carbon black into the reaction kettle, mix and stir evenly, heat up to 65 degrees Celsius, and react for 25 minutes;

[0026] 2) Continue to add 13 parts of methanol and 0.6 parts of aluminum foam when the temperature is 85 degrees Celsius, and mix and react for 25 minutes;

[0027] 3) Put the mixture obtained in step 2) into an internal mixer for mixing. The mixing temperature is 140° C., and the mixing time is 45 minutes. After the mixed material is discharged, it is dried, and the drying temperature is 105° C. , the drying time is 18h, the dried material passes through the water cooling tank, the flow rate of water is 1m / s, and the water-blocking filler is obtained, and the particle size of the water-blockin...

Embodiment 3

[0030] 1) Weighing according to the formula, 30 parts of modified cyclodextrin solution, 8 parts of polystyrene, 10 parts of polyα-olefin, 3 parts of calcium carbonate, 0.6 parts of stannous octoate, 0.3 parts of maleic acid, Put 10 parts of 1,4-butanediol and 6 parts of carbon black into the reaction kettle, mix and stir evenly, heat up to 70 degrees Celsius, and react for 30 minutes;

[0031] 2) Continue to add 16 parts of methanol and 0.8 parts of aluminum foam when the temperature is 90 degrees Celsius, and mix and react for 30 minutes;

[0032] 3) Put the mixture obtained in step 2) into an internal mixer for mixing. The mixing temperature is 150° C., and the mixing time is 60 minutes. After the mixed material is discharged, it is dried, and the drying temperature is 110° C. , the drying time is 24h, the dried material passes through the water cooling tank, the flow rate of water is 1m / s, and the water-blocking filler is obtained, and the particle size of the water-blocki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com