A fusion reactor solid-state water-cooled cladding tritium-producing multiplier-neutron multiplier

A technology of tritium breeder and water cooling pack, applied in the field of nuclear fusion engineering, can solve the problems of increasing the risk of accidents and achieve the effect of expanding the effective solid angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

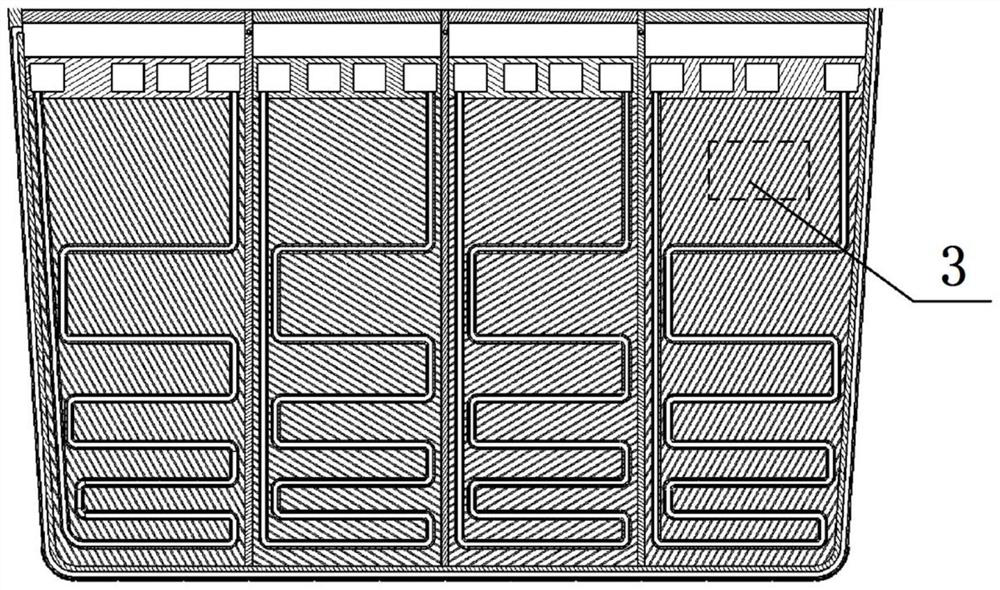

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

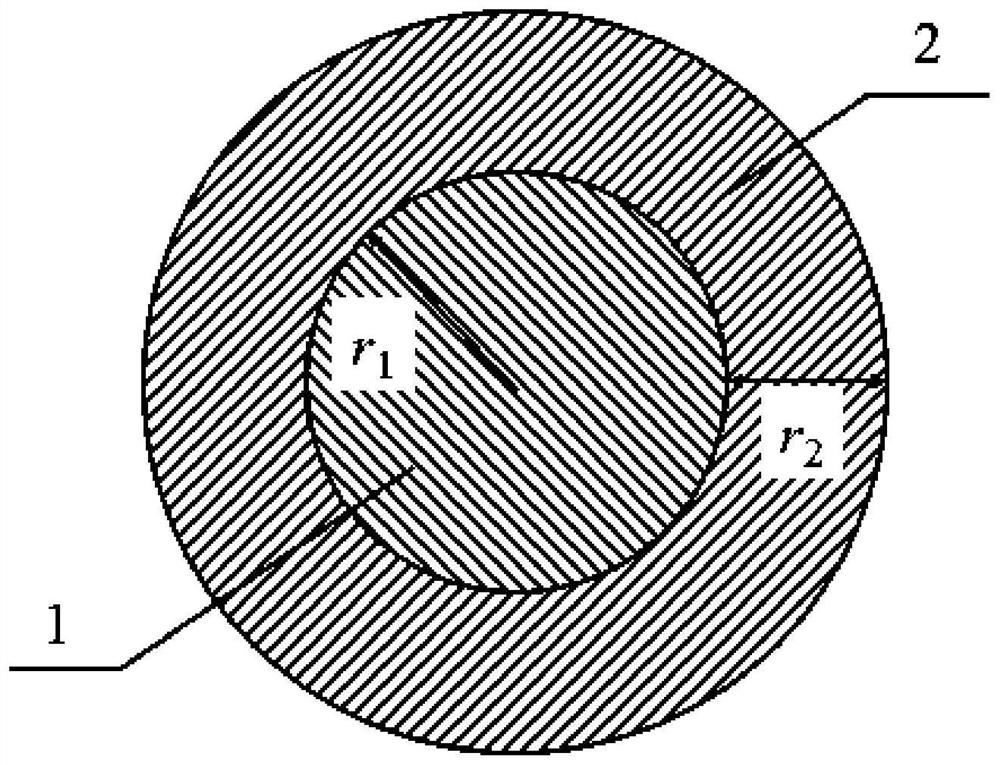

[0017] Such as figure 1 As shown, a solid-state water-cooled cladding tritium-producing multiplier-neutron multiplier for a fusion reactor adopts a multiphase core-shell spherical structure, in which the inner core is a beryllium ball 1, and the spherical shell is a ceramic lithium titanate 2, wherein The beryllium ball 1 is used as a multiplication area, and the ceramic lithium titanate 2 is used as a multiplication area to cover the beryllium ball for multiplying neutrons.

[0018] Assuming that the radius of the beryllium ball 1 as the multiplication zone is r1, and the thickness of the ceramic lithium titanate 2 as the multiplication zone is r2, then the ratio of r1 to r2 is 1:m, where the size of m depends on the design of the solid water cooling cladding of the fusion reactor The volume ratio of proliferator to multiplier in medium. In the curre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com