Graphene-coated pan-based ladder polymer ultra-short nanofibers and its preparation method and application

A nanofiber and graphene technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low conductivity and inferior conductivity of semiconductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

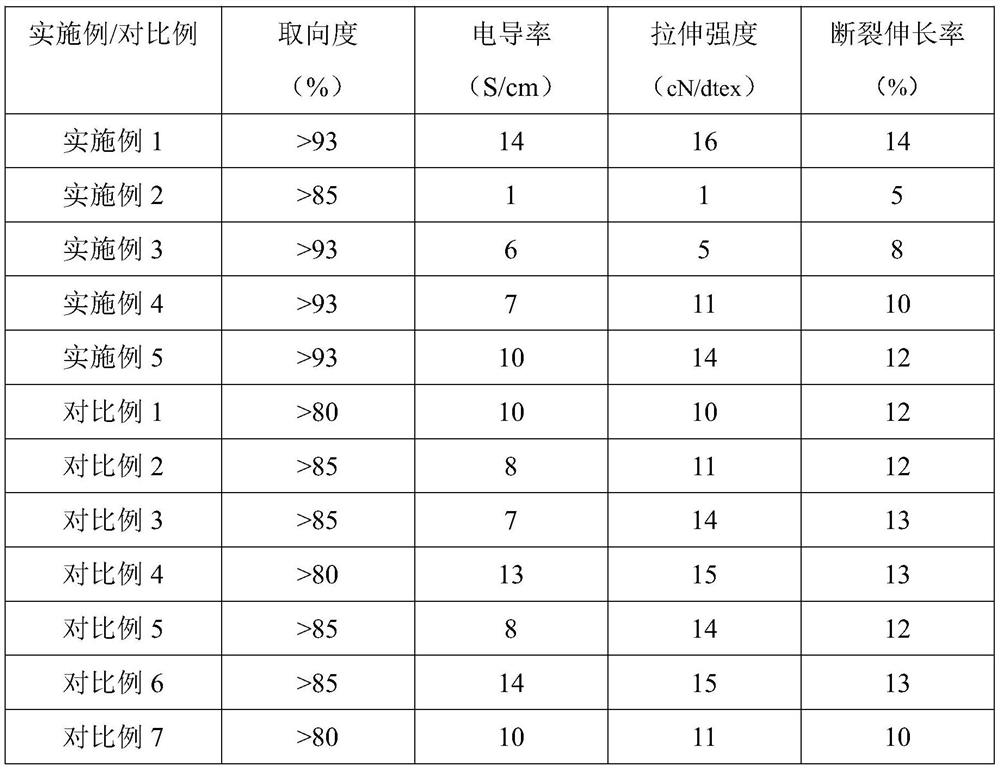

Examples

preparation example Construction

[0022] What the first aspect of the present invention provides is a kind of preparation method of graphene-coated PAN-based ladder polymer ultra-short nanofiber, and the steps include at least:

[0023] (1) the polyacrylonitrile fiber mat and / or non-woven fabric is impregnated with graphene dispersion, cut into strips after drying;

[0024] (2) Draw the strips with hot air at 80°C-150°C to prepare graphene-coated PAN electrospun oriented fiber tows;

[0025] (3) The electrospun oriented fiber tow is subjected to air oxidation and inert gas cyclization to form a graphene-coated PAN-based ladder polymer nanofiber oriented tow, which is further cut to obtain a graphene-coated PAN-based ladder polymer superstructure. short nanofibers.

[0026] The polyacrylonitrile described in the present invention is not particularly limited, and generally commercially available polyacrylonitrile can be used in the present invention. In the present invention, PAN is the abbreviation of polyacry...

Embodiment 1

[0058] Graphene is coated with the preparation method of PAN-based ladder polymer ultrashort nanofiber, and the steps comprise:

[0059] (1) the polyacrylonitrile non-woven fabric is impregnated with the graphene dispersion liquid, and cut into strips after drying;

[0060] (2) Hot air drawing is carried out to strip, prepares graphene-coated PAN electrospun oriented fiber tow;

[0061] (3) The electrospun oriented fiber tow is subjected to air oxidation and inert gas cyclization to form a graphene-coated PAN-based ladder polymer nanofiber oriented tow, which is further cut to obtain a graphene-coated PAN-based ladder polymer superstructure. short nanofibers;

[0062] The preparation of the polyacrylonitrile non-woven fabric in the step (1) is as follows: polyacrylonitrile and an appropriate amount of solvent are added to the polymerization reactor, stirred and dissolved to obtain a polyacrylonitrile solution, and electrospun in a high-voltage electric field is used. The sta...

Embodiment 2

[0065] Graphene is coated with the preparation method of PAN-based ladder polymer ultrashort nanofiber, and the steps comprise:

[0066] (1) the polyacrylonitrile fiber mat is impregnated with the graphene dispersion, and cut into strips after drying;

[0067] (2) Hot air drawing is carried out to strip, prepares graphene-coated PAN electrospun oriented fiber tow;

[0068] (3) The electrospun oriented fiber tow is subjected to air oxidation and inert gas cyclization to form a graphene-coated PAN-based ladder polymer nanofiber oriented tow, which is further cut to obtain a graphene-coated PAN-based ladder polymer superstructure. short nanofibers;

[0069] The preparation of the polyacrylonitrile fiber felt in the step (1) is as follows: polyacrylonitrile and an appropriate amount of solvent are added to the polymerization reactor, stirred and dissolved to obtain a polyacrylonitrile solution, and electrospun in a high-voltage electric field is carried out. The mesh belt is a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com