A kind of environment-friendly zinc-nickel alloy black passivation solution and its application method

A zinc-nickel alloy and passivation solution technology, applied in the field of passivation solution, can solve the problems of destroying the mechanical isolation effect, affecting the appearance of the film layer, poor salt spray resistance, etc., achieving uniform appearance of the film layer and satisfying high corrosion resistance. With excellent decorative, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

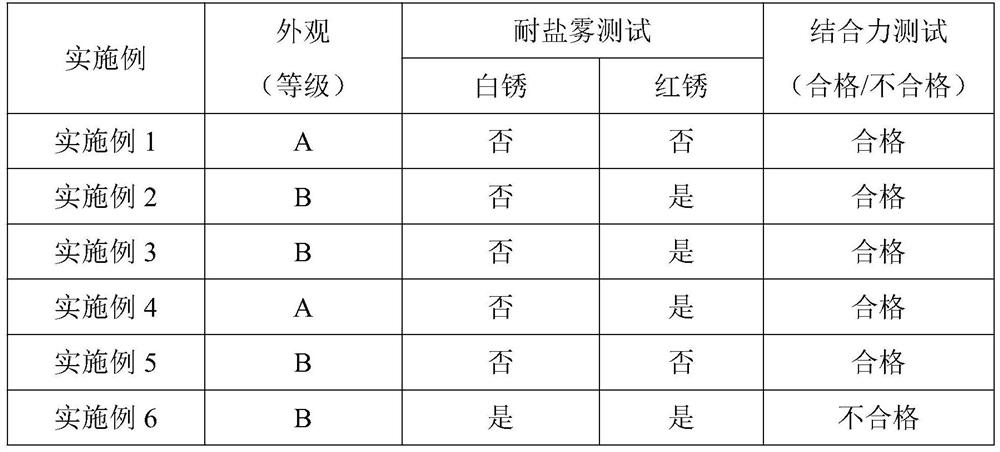

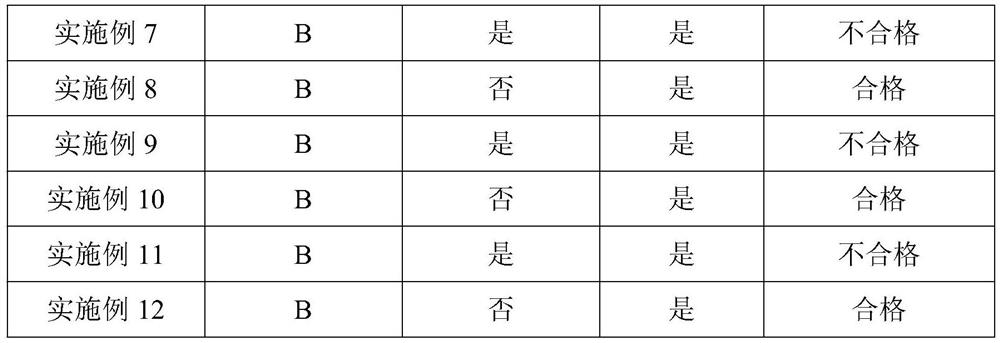

Examples

Embodiment 1

[0047] An environment-friendly zinc-nickel alloy black passivation solution, by weight percentage, raw materials include 32% trivalent chromium salt hydrate, 6% cobalt salt hydrate, 1% unsaturated ethylenic acid, 10% weak acid, and water to make up the rest quantity.

[0048] The weak acid is a combination of hydrofluoric acid and glacial acetic acid; the weight ratio of the hydrofluoric acid and glacial acetic acid is 1:4, and the hydrofluoric acid is a hydrofluoric acid aqueous solution with a mass concentration of 40%.

[0049] The trivalent chromium salt hydrate is chromium nitrate nonahydrate; the cobalt salt hydrate is cobalt nitrate hexahydrate; and the unsaturated ethylenic acid is maleic acid.

[0050] The preparation steps of the zinc-nickel alloy black passivation solution are as follows: add trivalent chromium salt hydrate into water, stir until completely dissolved; then add weak acid, unsaturated ethylenic acid, and cobalt salt hydrate in sequence, and heat up to...

Embodiment 2

[0053] An environment-friendly zinc-nickel alloy black passivation solution, the raw materials include, by weight percentage, 25% trivalent chromium salt hydrate, 3% cobalt salt hydrate, 0.5% unsaturated ethylenic acid, 5% weak acid, and water to make up the rest quantity.

[0054] The weak acid is a combination of oxalic acid and glacial acetic acid; the weight ratio of hydrofluoric acid and glacial acetic acid is 1:2, and the hydrofluoric acid is a hydrofluoric acid aqueous solution with a mass concentration of 40%.

[0055] The trivalent chromium salt hydrate is chromium sulfate hexahydrate; the cobalt salt hydrate is cobalt nitrate hexahydrate; and the unsaturated ethylenic acid is citraconic acid.

[0056] The preparation steps of the zinc-nickel alloy black passivation solution are as follows: add trivalent chromium salt hydrate into water, stir until completely dissolved; then add weak acid, unsaturated ethylenic acid, and cobalt salt hydrate in sequence, and heat up to...

Embodiment 3

[0059] An environment-friendly zinc-nickel alloy black passivation solution, the raw materials include 35% trivalent chromium salt hydrate, 8% cobalt salt hydrate, 1.5% unsaturated ethylenic acid, 12% weak acid, and water to make up the rest quantity.

[0060] The weak acid is a combination of hydrofluoric acid, glacial acetic acid and oxalic acid; the weight ratio of the hydrofluoric acid and glacial acetic acid is 1:6:0.5, and the hydrofluoric acid is a hydrofluoric acid aqueous solution with a mass concentration of 40%.

[0061] The trivalent chromium salt hydrate is chromium nitrate nonahydrate; the cobalt salt hydrate is cobalt nitrate hexahydrate; and the unsaturated ethylenic acid is maleic acid.

[0062] The preparation steps of the zinc-nickel alloy black passivation solution are as follows: add trivalent chromium salt hydrate into water, stir until completely dissolved; then add weak acid, unsaturated ethylenic acid, and cobalt salt hydrate in sequence, and heat up t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com