A highly antibacterial ag@cu nanoparticle-modified pi nanofiber filament yarn

A nanofiber and nanoparticle technology, applied in fiber processing, fiber type, filament/wire forming, etc., can solve the problems of limiting the development of polyimide materials and general antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

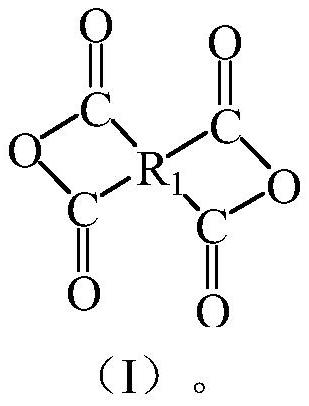

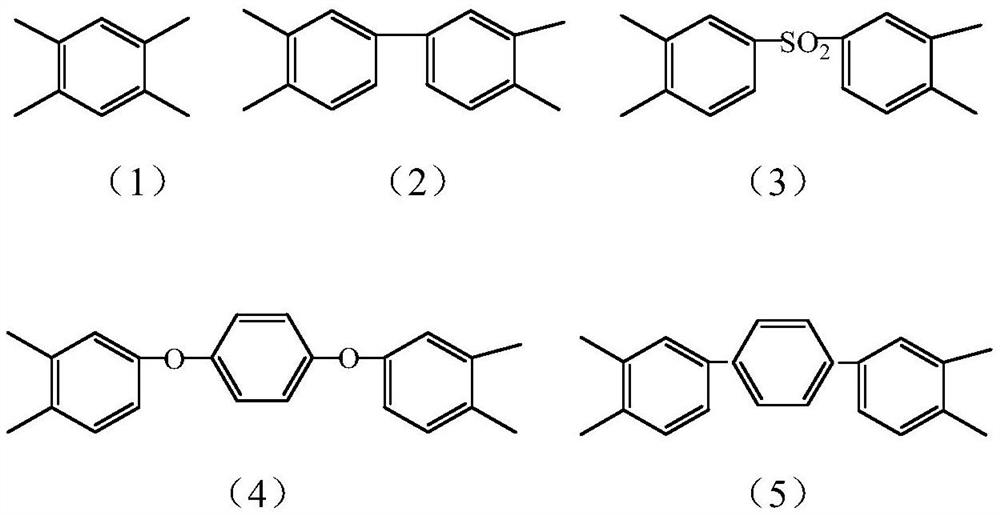

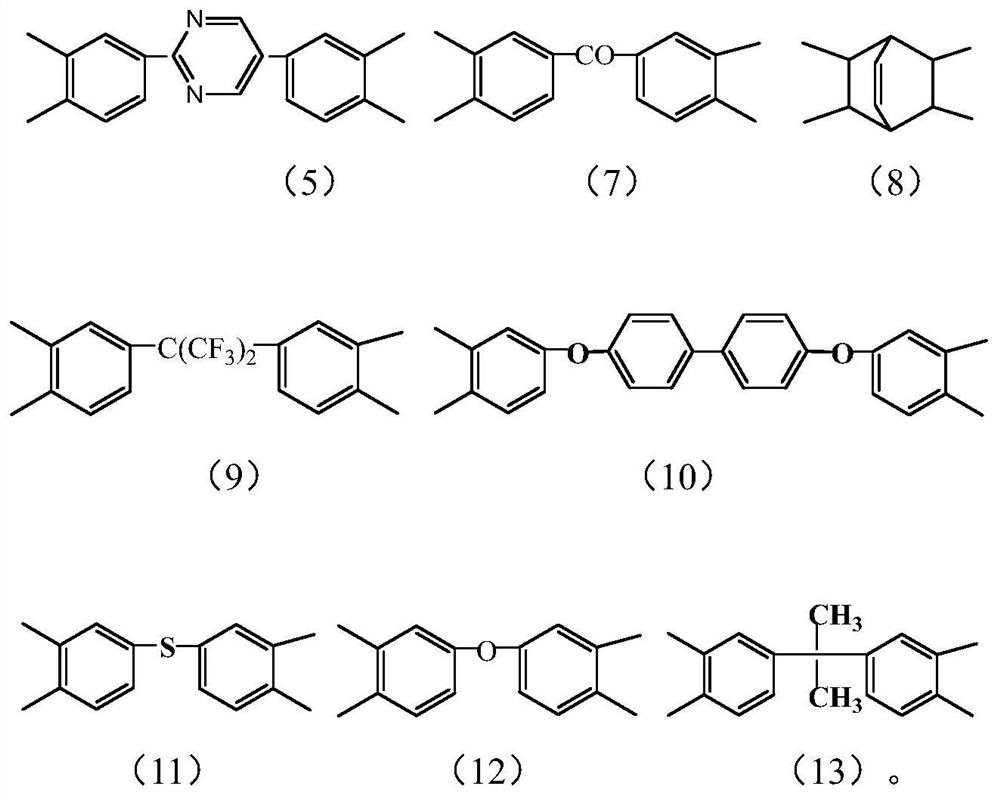

[0023] The second aspect of the present invention provides a method for preparing the high antibacterial Ag@Cu nanoparticles modified PI nanofiber long yarn, the steps at least include:

[0024] (1) spinning: electrospinning the polyamic acid solution to prepare polyamic acid nanofiber mats and / or nonwovens;

[0025] (2) Impregnation: the polyamic acid nanofiber mat and / or non-woven fabric is impregnated with copper salt solution and / or silver salt solution; the mass concentration of described copper salt solution is 0.1-2wt%, and the mass concentration of silver salt solution is 0.1-2wt%;

[0026] (3) drafting: after drying, slitting into strips, heating and drafting to prepare oriented nanofiber bundles decorated with metal nanoparticles;

[0027] (4) Twisting: Twisting the oriented nanofiber bundles decorated with metal nanoparticles.

[0028] In some embodiments, the preparation method of the highly antibacterial Ag@Cu nanoparticles modified PI nanofiber long yarn, the s...

Embodiment 1

[0075] A high antibacterial Ag@Cu nanoparticle modified PI nanofiber long yarn, the continuous length of the nanofiber long yarn is more than 2500 meters, the degree of orientation is 81%, and the linear density is 3.1Tex;

[0076] The preparation method of highly antibacterial Ag@Cu nanoparticles modified PI nanofiber long yarn described in this embodiment, the steps include:

[0077] (1) Spinning: After the dianhydride and diamine monomers are purified, they are added to the polymerization reactor together with an appropriate amount of solvent, stirred and reacted for a period of time to obtain a polyamic acid solution, and the polyamic acid solution is placed in a high-voltage electric field Implementing electrospinning in the process, using a stainless steel mesh belt as a collector, collecting polyamic acid nanofiber felts;

[0078] (2) Impregnation: impregnating the electrospun polyamic acid nanofiber mat obtained above in a mixed aqueous solution of copper salt and silv...

Embodiment 2

[0083]A high antibacterial Ag@Cu nanoparticle modified PI nanofiber long yarn, the continuous length of the nanofiber long yarn is more than 2500 meters, the degree of orientation is 75%, and the linear density is 19.4Tex;

[0084] The preparation method of highly antibacterial Ag@Cu nanoparticles modified PI nanofiber long yarn described in this embodiment, the steps include:

[0085] (1) Spinning: After the dianhydride and diamine monomers are purified, they are added to the polymerization reactor together with an appropriate amount of solvent, stirred and reacted for a period of time to obtain a polyamic acid solution, and the polyamic acid solution is placed in a high-voltage electric field Implementing electrospinning in the process, using a stainless steel mesh belt as a collector, collecting polyamic acid nanofiber felts;

[0086] (2) Impregnation: impregnating the electrospun polyamic acid nanofiber mat obtained above in a mixed aqueous solution of copper salt and silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com