A vertical cavity surface emitting laser and its manufacturing method

A vertical cavity surface emission and laser technology, applied in the field of lasers, can solve the problems of uneven VCSEL power and adverse effects on crystal quality, and achieve the effect of improving power uniformity and good crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

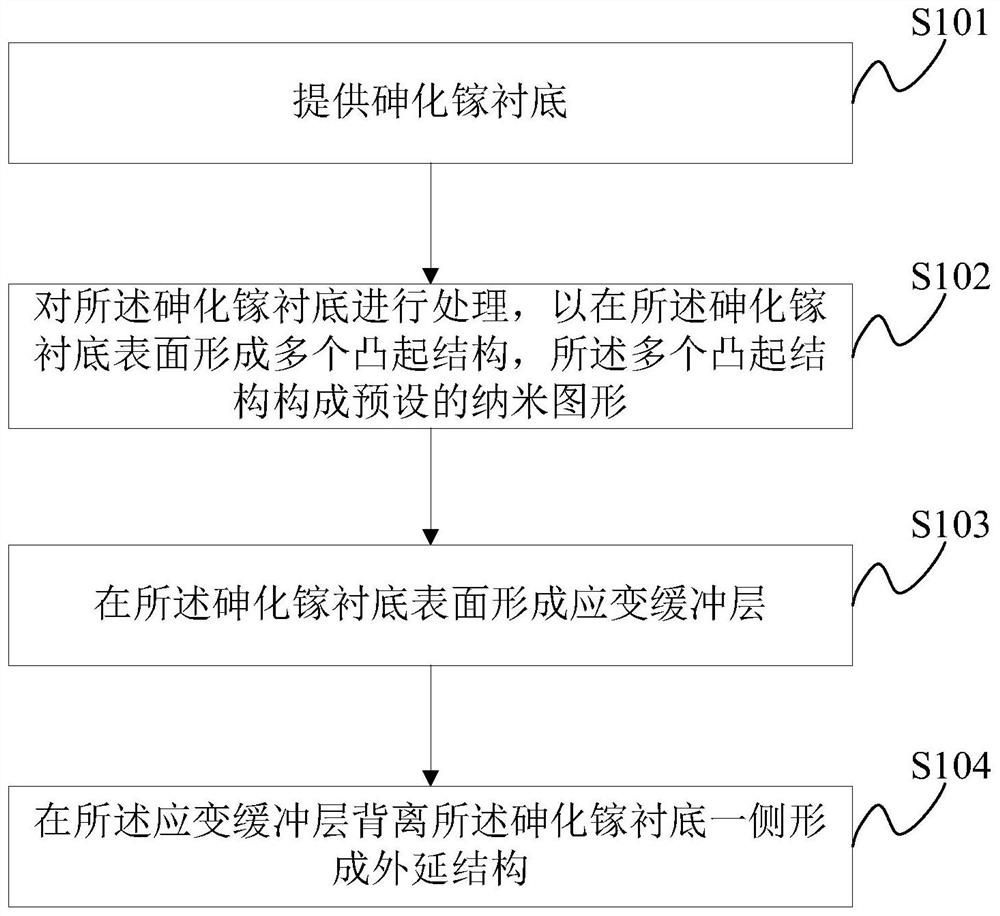

[0047] The embodiment of the present application provides a preparation method of a vertical cavity surface emitting laser, such as figure 1 shown, including:

[0048] S101: providing a gallium arsenide substrate;

[0049] Such as figure 2 as shown, figure 2 shows a schematic cross-sectional view of the gallium arsenide substrate provided in step S101; figure 2 The number 10 in represents the gallium arsenide substrate;

[0050] S102: Processing the gallium arsenide substrate to form a plurality of raised structures on the surface of the gallium arsenide substrate, the plurality of raised structures forming a preset nano-pattern;

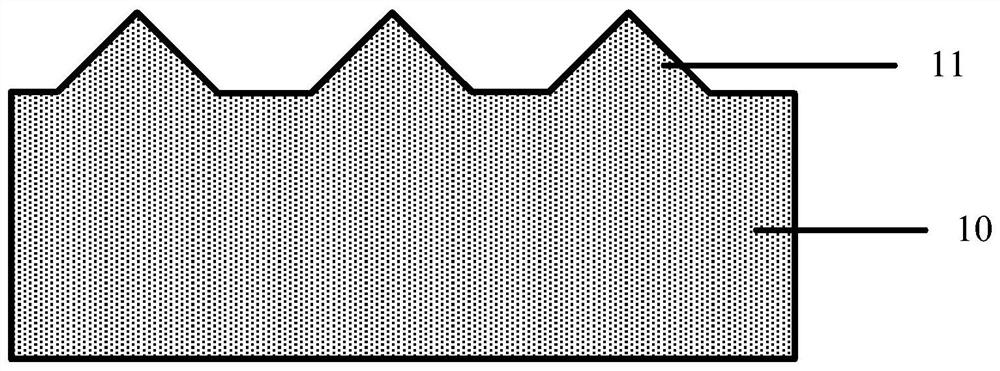

[0051] refer to image 3 , image 3 A schematic cross-sectional structure diagram showing the gallium arsenide substrate and its surface structure after step S102; image 3 The number 11 in represents the raised structure.

[0052] S103: forming a strain buffer layer on the surface of the gallium arsenide substrate;

[0053] refer to F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com