Preparation method of three-way catalyst for single-coated gasoline car

A three-way catalyst, gasoline vehicle technology, applied in chemical instruments and methods, physical/chemical process catalysts, mechanical equipment, etc., can solve problems such as reduction in reduction performance, and achieve the effect of inhibiting growth and good durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

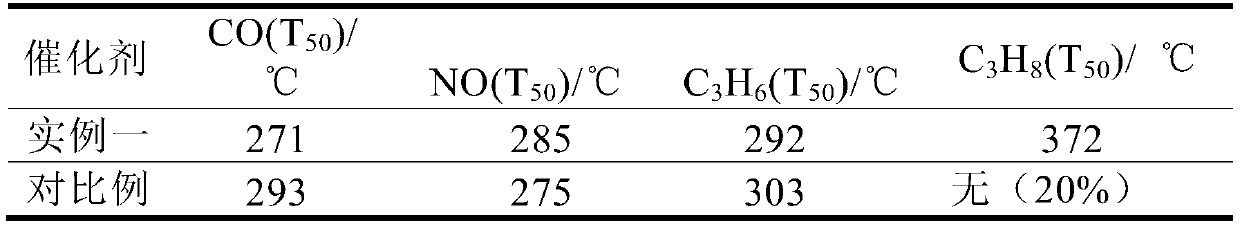

Embodiment 1

[0043] A preparation method of a single-coated three-way catalyst for gasoline vehicles, comprising the steps of:

[0044] ZrP 2 o 7 @La-Al 2 o 3 Material preparation:

[0045] (1) Synthesis of ZrP 2 o 7 @La-Al 2 o 3 Weighing of required materials: weigh ZrO(NO 3 ) 2 、H 3 PO 4 、La-Al 2 o 3 materials, among them, ZrO(NO 3 ) 2 and H 3 PO 4 respectively dissolved in a certain amount of deionized water;

[0046] (2), ZrP 2 o 7 Synthesis of materials: ZrO(NO 3 ) 2 The solution was slowly added to H 3 PO 4 solution, stirred for 60 minutes;

[0047] (3), core-shell structure ZrP 2 o 7 @La-Al 2 o 3 The synthesis of: the La-Al in step (1) 2 o 3 Material is added in the step (2);

[0048] (4), hydrothermal treatment: take the material of step (3) and transfer it to the reactor, and heat it in a water bath at 80° C. for 5 hours;

[0049] (5), washing: the material in step (4) is washed 3 times with deionized water;

[0050] (6) Material drying and roastin...

Embodiment 2

[0067] A preparation method of a single-coated three-way catalyst for gasoline vehicles, comprising the steps of:

[0068] ZrP 2 o 7 @La-Al 2 o 3 Material preparation:

[0069] (1) Synthesis of ZrP 2 o 7 @La-Al 2 o 3 Weighing of required materials: weigh ZrO(NO 3 ) 2 、H 3 PO 4 、La-Al 2 o 3 materials, among them, ZrO(NO 3 ) 2 and H 3 PO 4 respectively dissolved in a certain amount of deionized water;

[0070] (2), ZrP 2 o 7 Synthesis of materials: ZrO(NO 3 ) 2 The solution was slowly added to H 3 PO 4 solution, stirred for 120 minutes;

[0071] (3), core-shell structure ZrP 2 o 7 @La-Al 2 o3 The synthesis of: the La-Al in step (1) 2 o 3 Material is added in the step (2);

[0072] (4), hydrothermal treatment: take the material of step (3) and transfer it to the reactor, and heat it in a water bath at 90° C. for 12 hours;

[0073] (5), washing: the material in step (4) is washed 3 times with deionized water;

[0074] (6) Material drying and roastin...

Embodiment 3

[0091] A preparation method of a single-coated three-way catalyst for gasoline vehicles, comprising the steps of:

[0092] ZrP 2 o 7 @La-Al 2 o 3 Material preparation:

[0093] (1) Synthesis of ZrP 2 o 7 @La-Al 2 o 3 Weighing of required materials: Weigh ZrO(NO 3 ) 2 、H 3 PO 4 、La-Al 2 o 3 materials, among them, ZrO(NO 3 ) 2 and H 3 PO 4 respectively dissolved in a certain amount of deionized water;

[0094] (2), ZrP 2 o 7 Synthesis of materials: ZrO(NO 3 ) 2 The solution was slowly added to H 3 PO 4 In the solution, stir strongly for 240 minutes;

[0095] (3), core-shell structure ZrP 2 o 7 @La-Al 2 o 3 The synthesis of: the La-Al in step (1) 2 o 3 Material is added in the step (2);

[0096] (4), hydrothermal treatment: take the material of step (3) and transfer it to the reactor, and heat it in a water bath at 85° C. for 24 hours;

[0097] (5), washing: the material in step (4) is washed 3 times with deionized water;

[0098] (6) Material dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com