Supersonic airflow traditional Chinese medicinal material crushing equipment

A technology of supersonic air flow and crushing equipment, which is applied in the direction of making medicines into special physical or ingestible devices, grain processing, etc., and can solve the problems of low processing added value, difficulty in fully exerting drug effects, and waste of biological resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

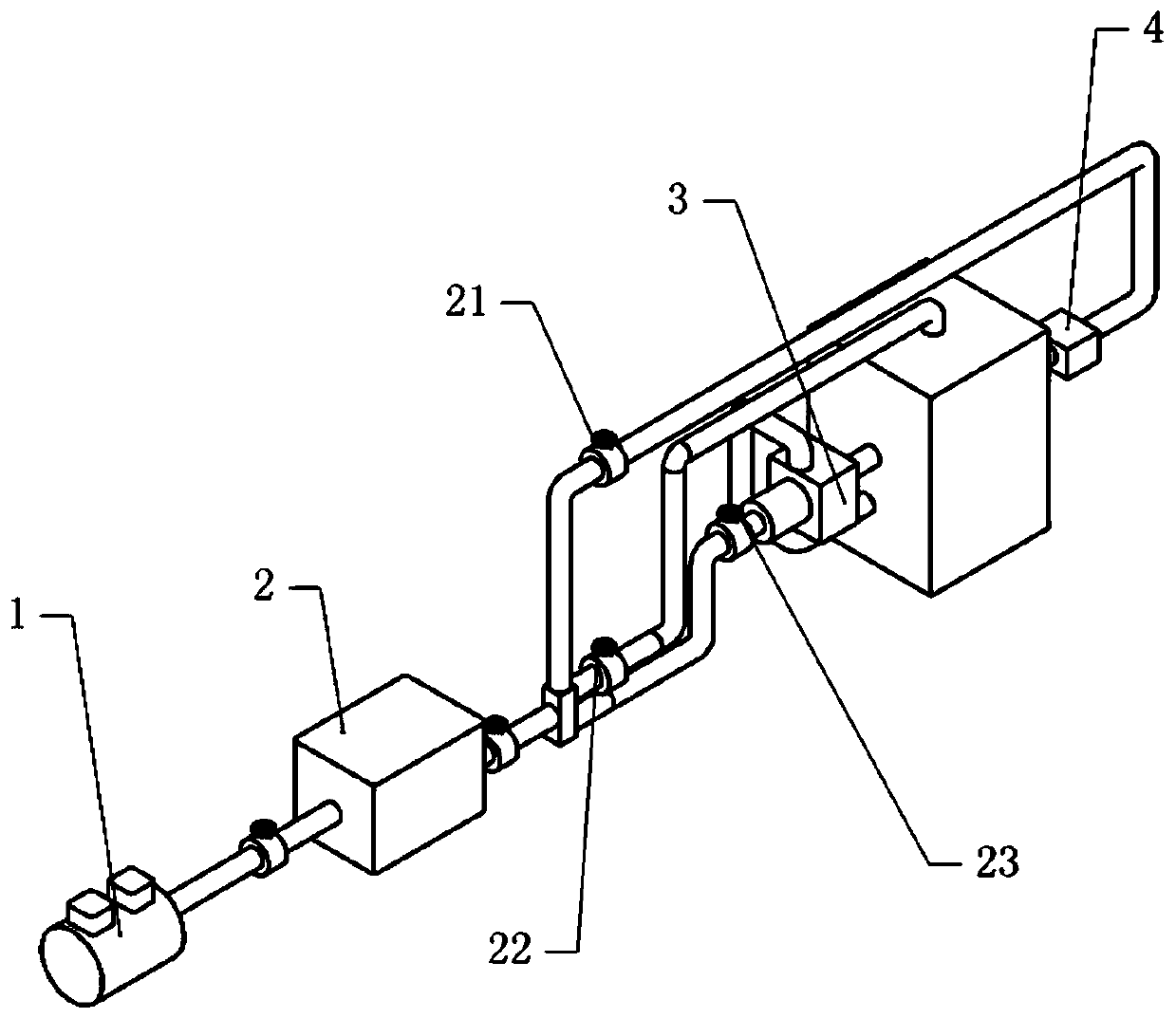

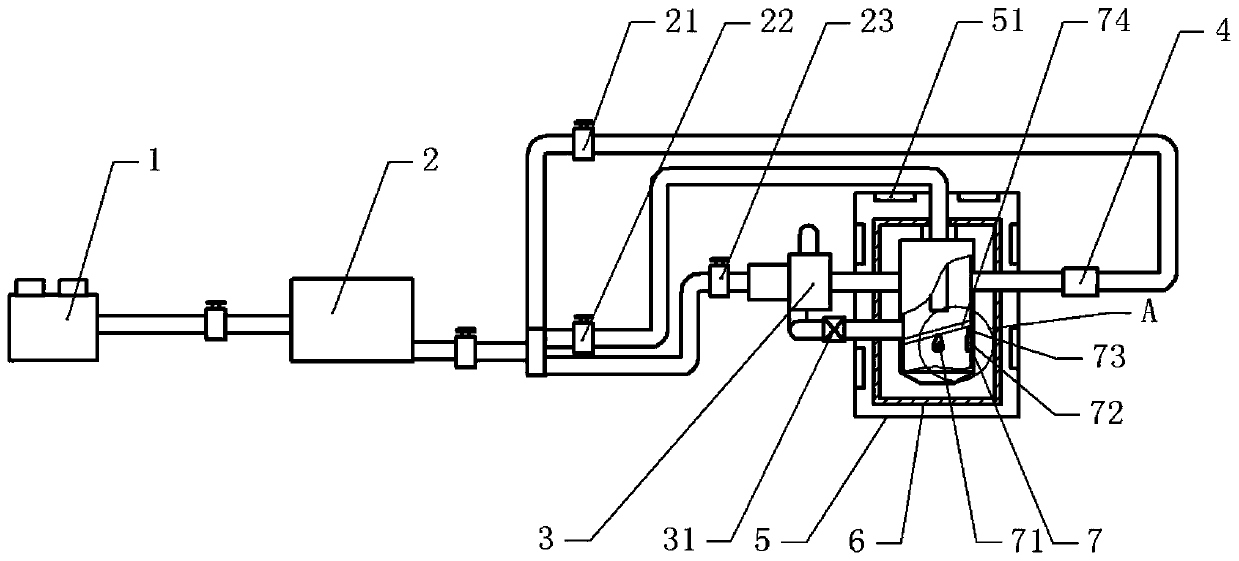

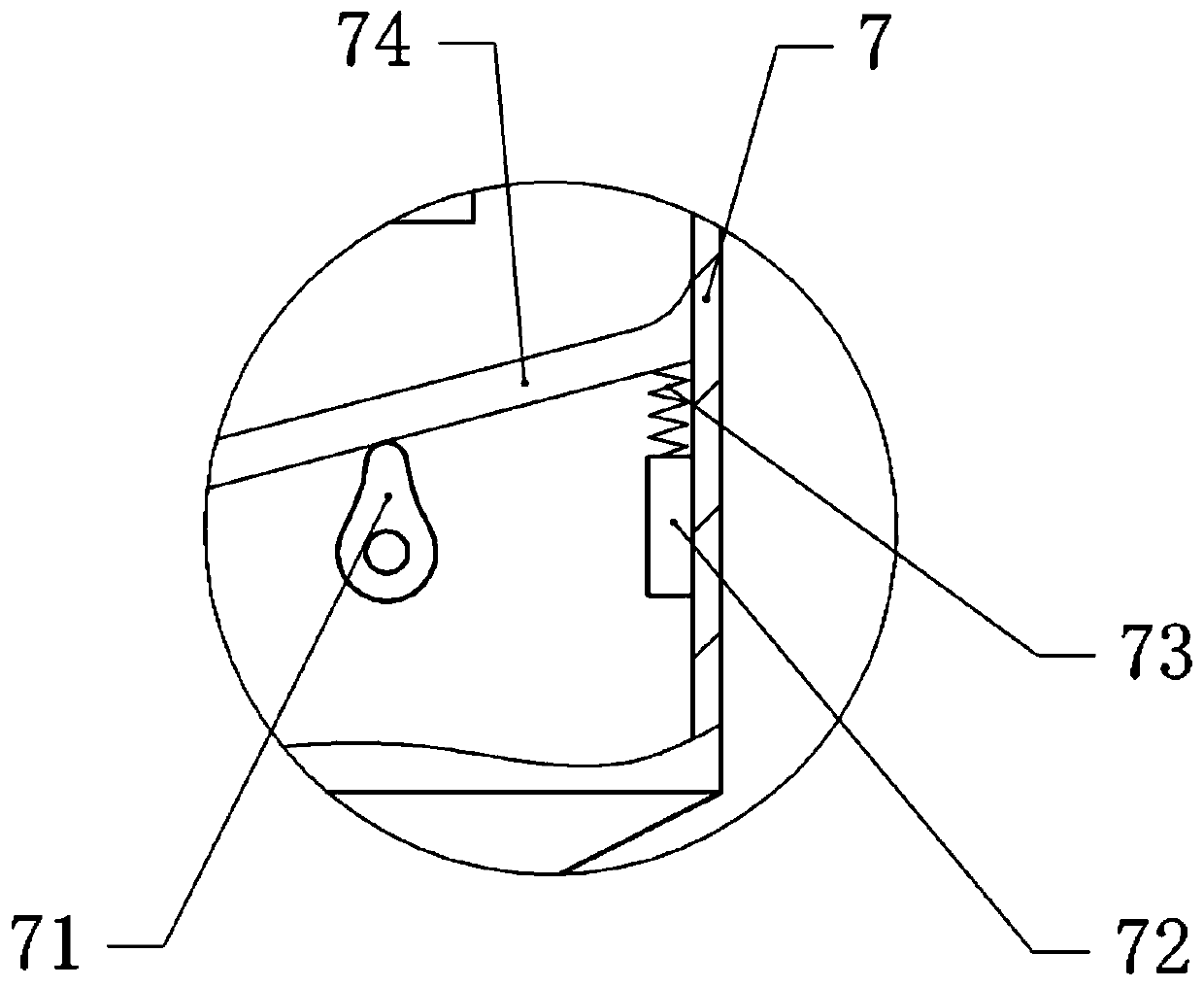

[0030] A kind of crushing equipment for Chinese medicinal materials in supersonic airflow, as attached figure 1 , attached figure 2 And attached image 3 Shown, comprise gas compressor 1, purifier 2 and pulverizer, the model of gas compressor 1 in the present embodiment is: eyele leopard 1236, and the outlet of gas compressor 1 communicates with the inlet of purifier 2 through star valve, The outlet of the purifier 2 is also connected with a star valve and the star valve is connected with a multi-way pipe. In this embodiment, the multi-way pipe is a four-way pipe. The model of the purifier 2 in this embodiment is: 10HP. The gas compressed by the gas compressor 1 is any one of air, carbon dioxide, nitrogen, oxygen, helium, and argon, and nitrogen in this embodiment. The gas compressor 1 is connected with a nitrogen source, and the gas compressor 1 compresses the nitrogen, and the speed of the compressed gas can reach 1 to 4 times the speed of sound, preferably 3 times the sp...

Embodiment 2

[0041] The difference from Embodiment 1 is that, as shown in the appendix Figure 4 and Figure 5 As shown, two closing plates 75 are provided at the upper opening of the pulverizing body 7, and the closing plates 75 are connected with the pulverizing body 7 in a horizontal sliding connection. Inside the mouth, and the closing plate 75 is provided with rubber, when the closing plate 75 and the crushing body 7 are squeezed, the rubber is deformed to close the gap between the closing plate 75 and the opening.

[0042] It also includes two linear motor modules 76 fixed on the crushing body 7, and the closing plates 75 are respectively fixed on the linear motor modules 76. In this embodiment, the model of the linear motor module 76 is: 365823, and the brand is: Moka . The linear motor module 76 is electrically connected with a PLC controller whose model is: FX3U-16, and a program for controlling the horizontal reciprocating motion of the linear motor module 76 is preset in the P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com