Honeycomb core depression compensation method

A compensation method and honeycomb core technology, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve the problems of large depth of depression in the honeycomb core, aerodynamic depression on the surface of the honeycomb core, collapse of the honeycomb sandwich structure, etc. , to achieve good bonding effect, small surface depression depth, and improved shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

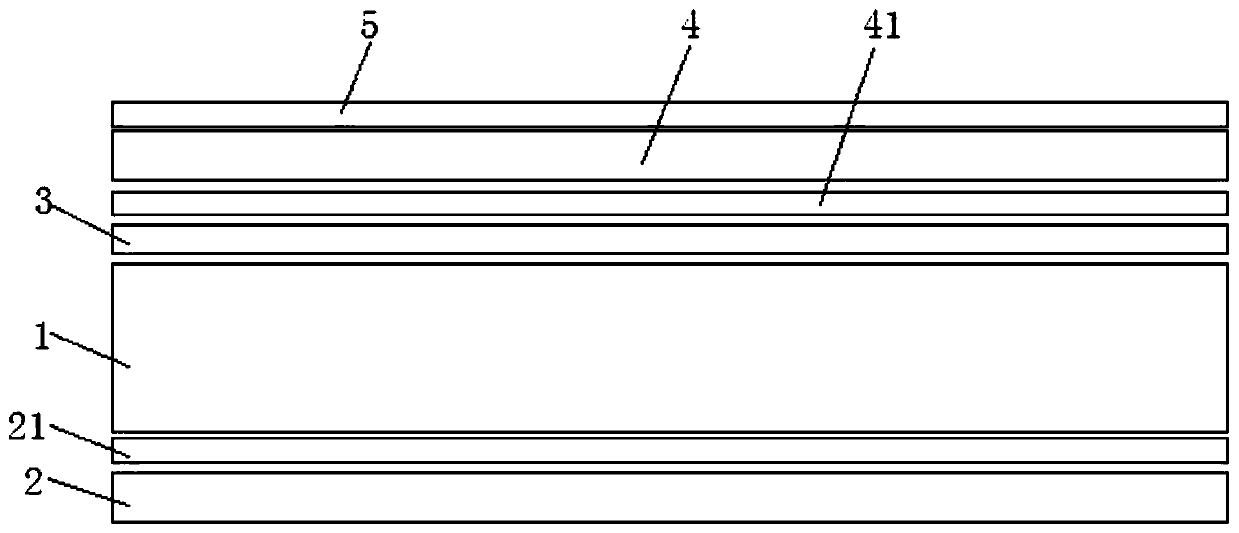

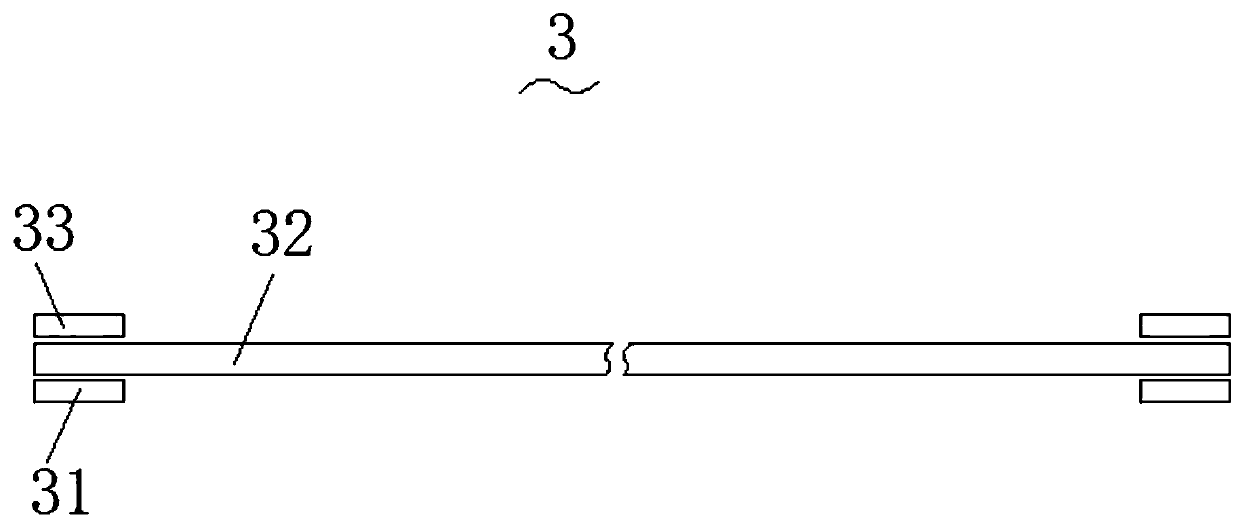

[0058] Take out the raw material honeycomb core, measure the maximum depth of the sunken area of the honeycomb core to be 1.5mm, and start the compensation operation:

[0059] S1. Raw material pretreatment:

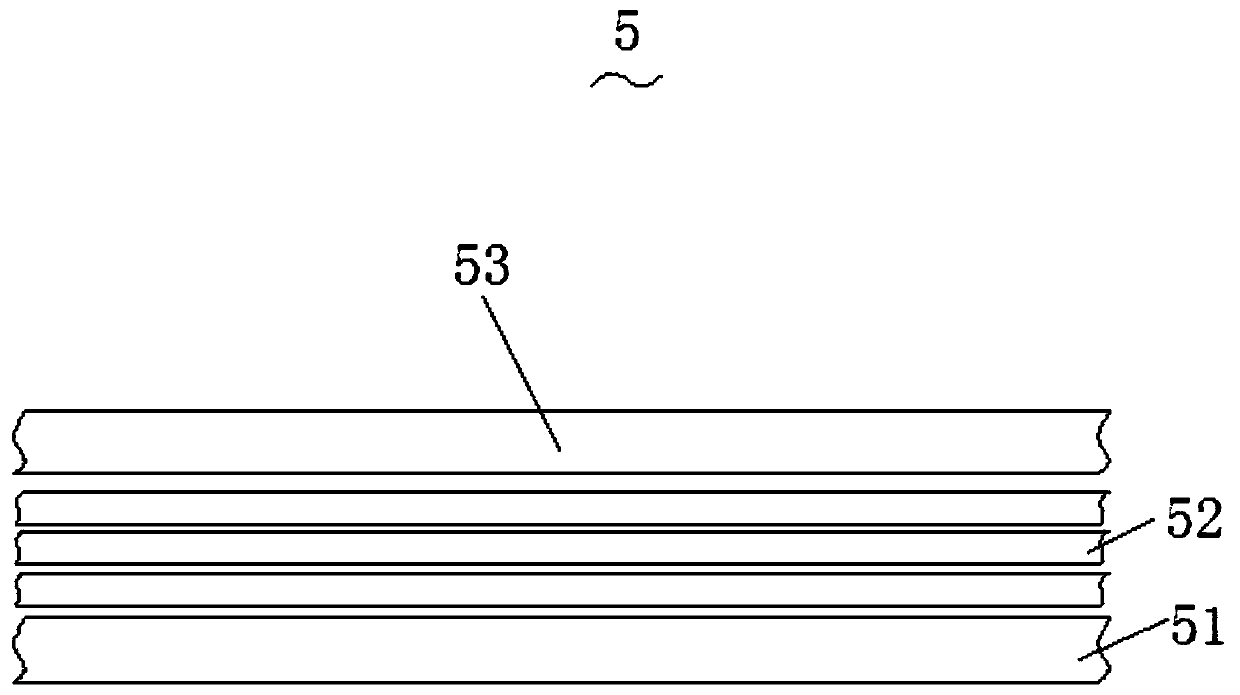

[0060] Roughen the surface to be glued on the upper panel 2 and lower panel 4; use 120-mesh sandpaper to roughen the surface to be glued on the panel, first roughen in the same direction (parallel to the axis direction), and then in the vertical axis direction and +45° , Coarsening in the direction of 135° requires uniform and irregular coarsening;

[0061]Remove impurities on the surface of the honeycomb core; blow the surface of the honeycomb core with oil-free compressed air to remove impurities and all excess on the surface (completed outside the clean room); clean and polish the surface of the honeycomb core with acetone until it is free of pollution, at least 3 After cleaning, dry at room temperature for 30 minutes;

[0062] S2. Lower panel assembly:

[0063] L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com