Novel production process for maleic anhydride through two-stage solvent absorption

A solvent absorption and production process technology, applied in the field of maleic anhydride production, can solve the problems of system shutdown, heat exchange system and analysis vacuum system blockage, etc., to reduce absorption and cooling load, avoid equipment investment waste, and improve parking cleaning system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

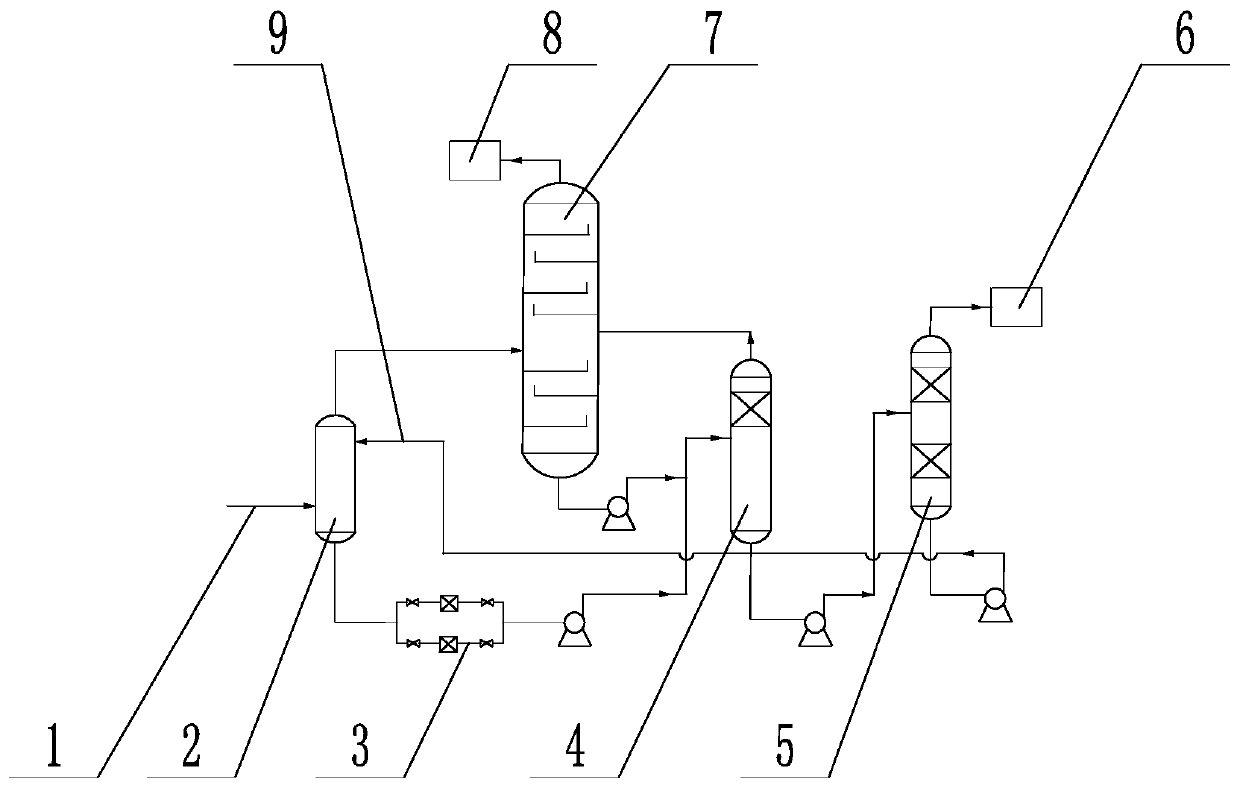

[0026] A novel two-stage solvent absorption maleic anhydride production process comprises the following steps:

[0027] (1) The maleic anhydride reaction product gas at 150°C is fed from the lower part of the pre-absorption tower 2 through the reaction product gas line 1, and the solvent is fed from the top of the pre-absorption tower 2, and the reaction product gas is cut off from the solvent in the pre-absorption tower 2 to mix;

[0028] (2) The solvent in the pre-absorption tower 2 pre-absorbs the reaction product gas, and the gas phase at the top of the tower enters the absorption tower 7 and is absorbed again by the solvent. The bottom of the pre-absorption tower 2 is a section of rich solvent that has absorbed maleic anhydride and high freezing point substances;

[0029] (3) After the absorption of the absorption tower 7 is completed, the tower top gas phase enters the waste gas treatment unit 8, and the bottom of the absorption tower 7 is the second section rich solvent...

Embodiment 2

[0033] A novel two-stage solvent absorption maleic anhydride production process comprises the following steps:

[0034] (1) Feed the maleic anhydride reaction gas at 170°C from the lower part of the pre-absorption tower 2 through the reaction gas pipeline 1, and feed the solvent from the top of the pre-absorption tower 2, and the reaction gas is cut off from the solvent in the pre-absorption tower 2 to mix;

[0035] (2) The solvent in the pre-absorption tower 2 pre-absorbs the reaction product gas, and the gas phase at the top of the tower enters the absorption tower 7 and is absorbed again by the solvent. The bottom of the pre-absorption tower 2 is a section of rich solvent that has absorbed maleic anhydride and high freezing point substances;

[0036] (3) After the absorption of the absorption tower 7 is completed, the tower top gas phase enters the waste gas treatment unit 8, and the bottom of the absorption tower 7 is the second section rich solvent that has absorbed malei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com