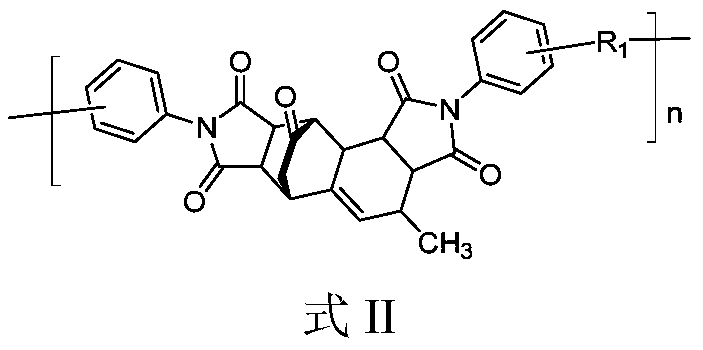

Colorless polyimide, and preparation method and application thereof

A technology of polyimide and products, which is applied in the application of substrates and resin products, and in the field of thin films, which can solve the problems of not being able to meet the requirements of device processing technology and the increase of thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

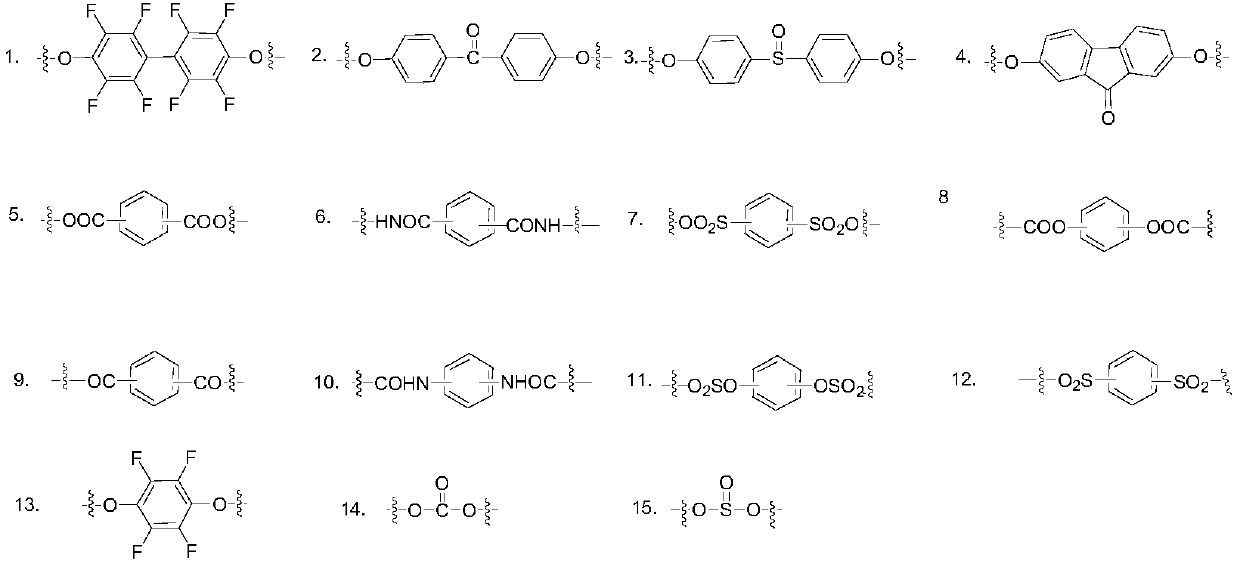

Method used

Image

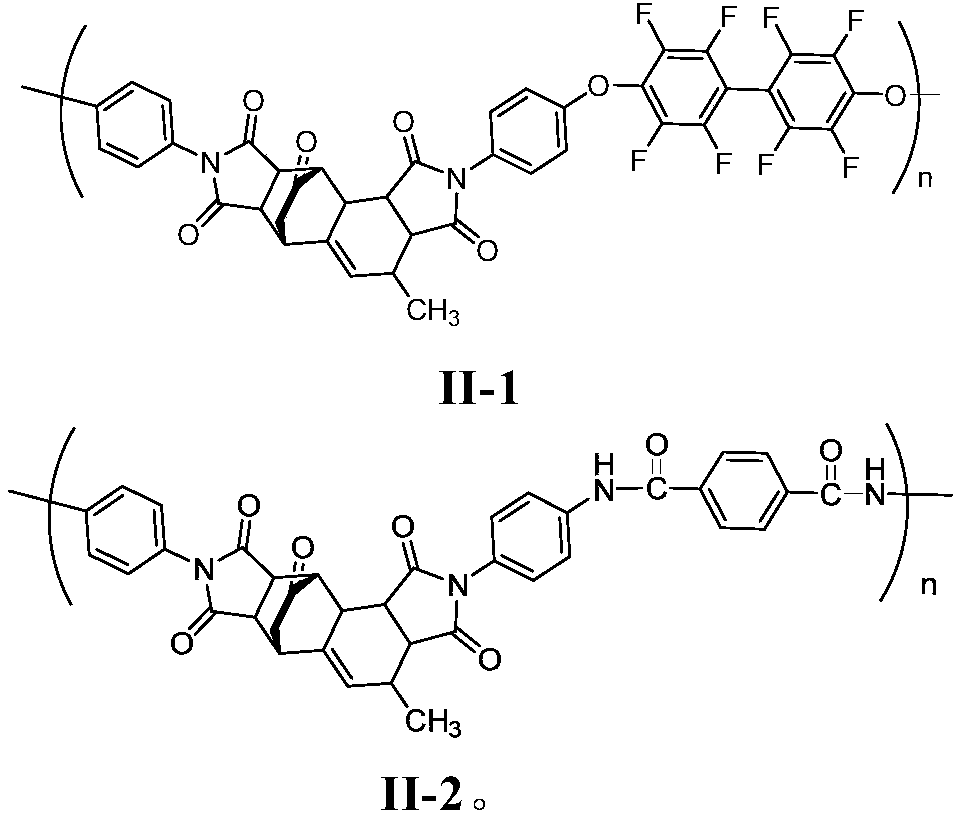

Examples

preparation example Construction

[0082] Its preparation method includes the following steps: dissolving the polyimide shown in formula II in N,N-dimethylformamide, N,N-dimethylacetamide, N-methylpyrrolidone, dimethyl base sulfoxide, cyclohexanone, or a combination thereof; pour the solution onto a clean and flat glass plate, scrape and coat it to form a film, let it evaporate and dry naturally, and then heat it under vacuum at 100-140°C for 10-30min to remove Remove the remaining solvent into a polyimide film.

[0083] The positive progress effect of the present invention is:

[0084] (1) The thermal stability of polyimide film prepared by the present invention is good, has high transparency simultaneously (light transmittance exceeds 75% under visible light 400nm-800nm wavelength range) glass transition temperature (> 360 ℃), low The coefficient of thermal expansion (<30ppm / °C) can meet the processing and application requirements of flexible substrate materials, provide key material support for the develo...

Embodiment 1

[0089] The preparation of embodiment 1 compound A

[0090]

[0091] Anethole (5g, 33.7mmol) and 4-maleimide phenol (14.0g, 74.2 mmol), 0.2mL N,N-dimethylaniline and 30mL ethyl acetate were added successively to 150mL sealed tube middle. Seal the tube, heat up to 140°C and react for 12 hours, then carry out column chromatography separation, ethyl acetate:petroleum ether (v:v=3:1) as the eluent, collect the product, and obtain 8.2g of white solid compound A, the product The rate is 44.2%.

[0092] 1 H NMR (400MHz, d 6 -DMSO,ppm)δ9.75(s,1H),9.67(s,1H),6.88~6.76(m,8H),5.63(d,J=31.5Hz,1H),4.94(dd,J=7.0, 2.0Hz, 1H), 3.59(dd, J=6.9, 2.9Hz, 1H), 3.38(m, 2H), 3.35(dd, J=7.9, 3.3Hz, 2H), 3.22(d, J=12.5Hz, 3H), 3.04(m 1H), 2.56(d, J=8.8Hz, 1H), 2.35(s, 1H), 1.45(d, J=7.3Hz, 3H).

[0093] 13 C NMR (101MHz, d 6 -DMSO, ppm) δ177.3, 177.1, 176.4, 174.9, 158.6, 157.3, 157.1, 140.6, 128.3, 127.9, 123.6, 123.3, 122.8, 115.5, 115.3, 92.9, 54.2, 45.8, 45.6, 43.1, 98.0 .

[0094] HRMS...

Embodiment 2

[0096] The preparation of embodiment 2 compound B

[0097]

[0098] Add compound A (0.4g, 0.7mmol), 50mL ethanol, 3mL concentrated hydrochloric acid to a 100ml single-necked bottle, stir at room temperature for 12h, NaHCO 3 The aqueous solution was neutralized to neutral, the solvent was removed by rotary evaporation, the product was washed with deionized water (20 mL×3), and dried in vacuo to obtain 0.3 g of compound B as a white solid, with a yield of 85.0%.

[0099] 1 H NMR (400MHz, d 6 -DMSO,ppm):δ9.78(s,1H),9.73(s,1H),6.94~6.78(m,8H),5.79(s,1H),3.51~3.47(m,2H),3.31~3.28 (m,1H),3.23~3.20(m,3H),2.95(m,1H),2.53(m,1H),2.19(d,J=5.6Hz,1H),1.88(d,J=18.8Hz, 1H), 1.42(d, J=7.3Hz, 3H).

[0100] 13 C NMR (101MHz, d 6 -DMSO, ppm): δ206.8, 176.8, 176.5, 176.5, 175.6, 157.5, 157.3, 139.4, 128.1, 128.0, 125.8, 123.1, 123.0, 115.5, 115.4, 48.3, 45.9, 45.1, 43.2, 12.6, 4.0, 4 38.9, 38.0, 36.1, 30.7, 30.1, 17.1.

[0101] HRMS (DART) m / z: Calcd for C 29 h 24 N 2 o 7 ,[M+H] +...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com