Semi-open type atmosphere-protecting and water-cooling device for laser cladding

A semi-open laser cladding technology, applied in the field of laser processing, can solve the problems of low cooling water flow efficiency, affecting the surface performance of the coating, insufficient atmosphere protection, etc., to achieve control of oxidation and impurity pollution, good water cooling effect, Wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The description will be further described below in conjunction with the drawings.

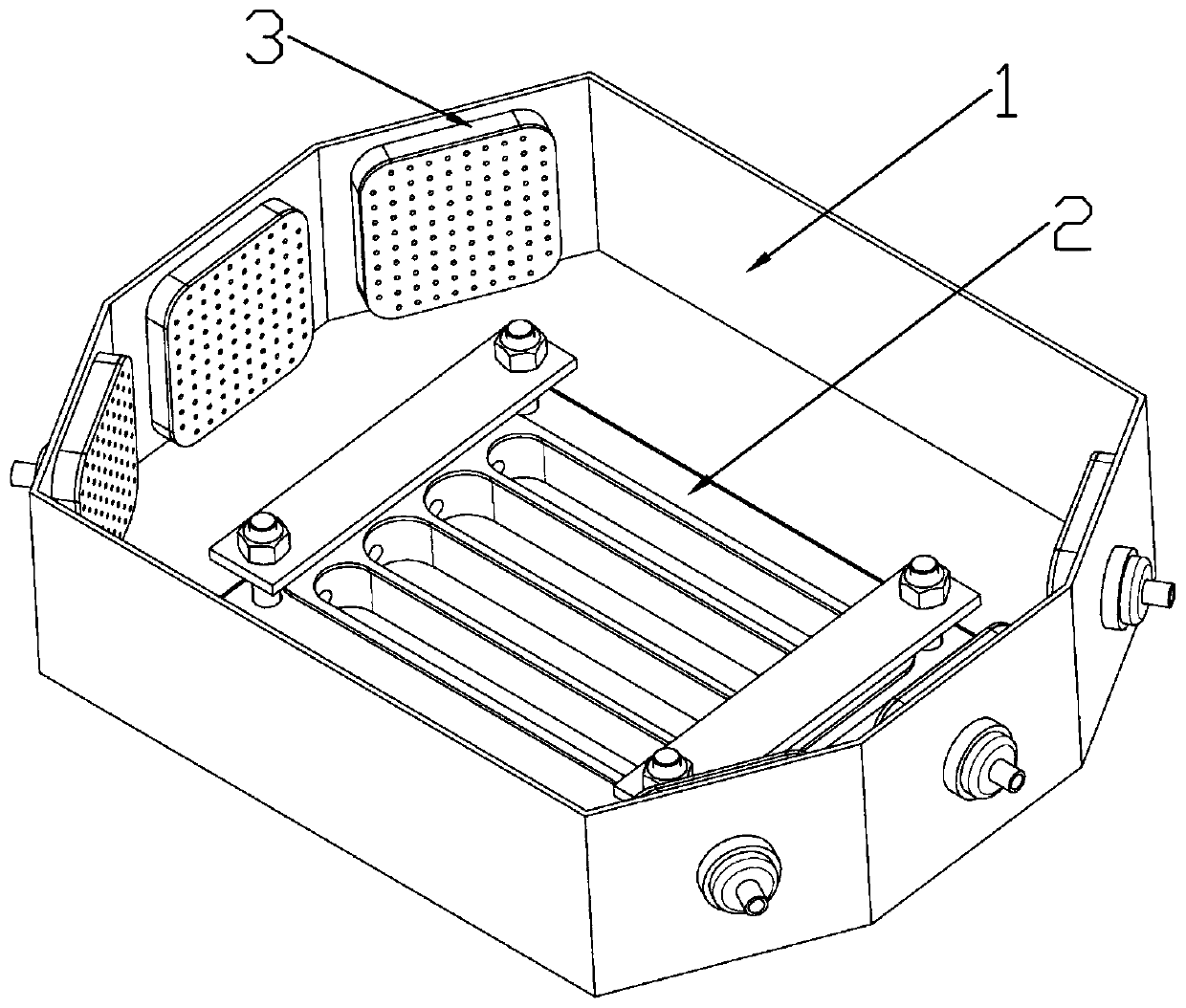

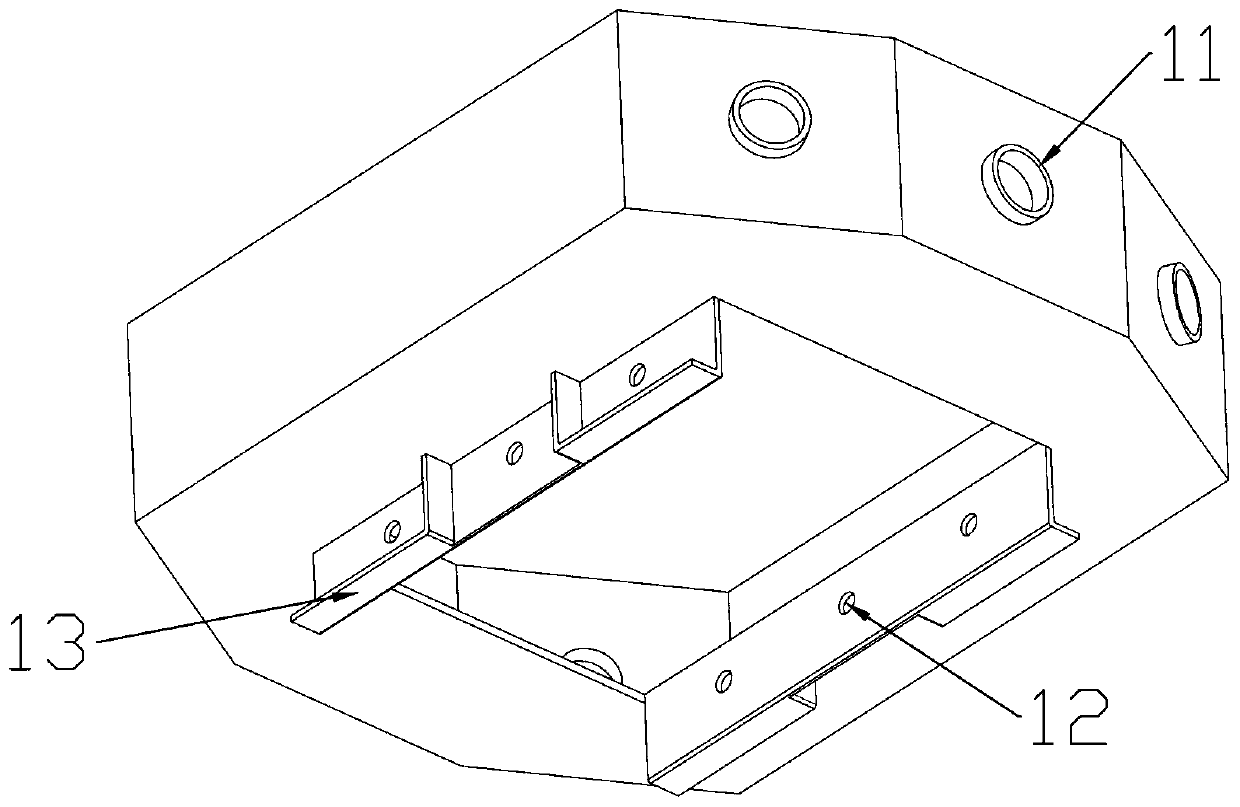

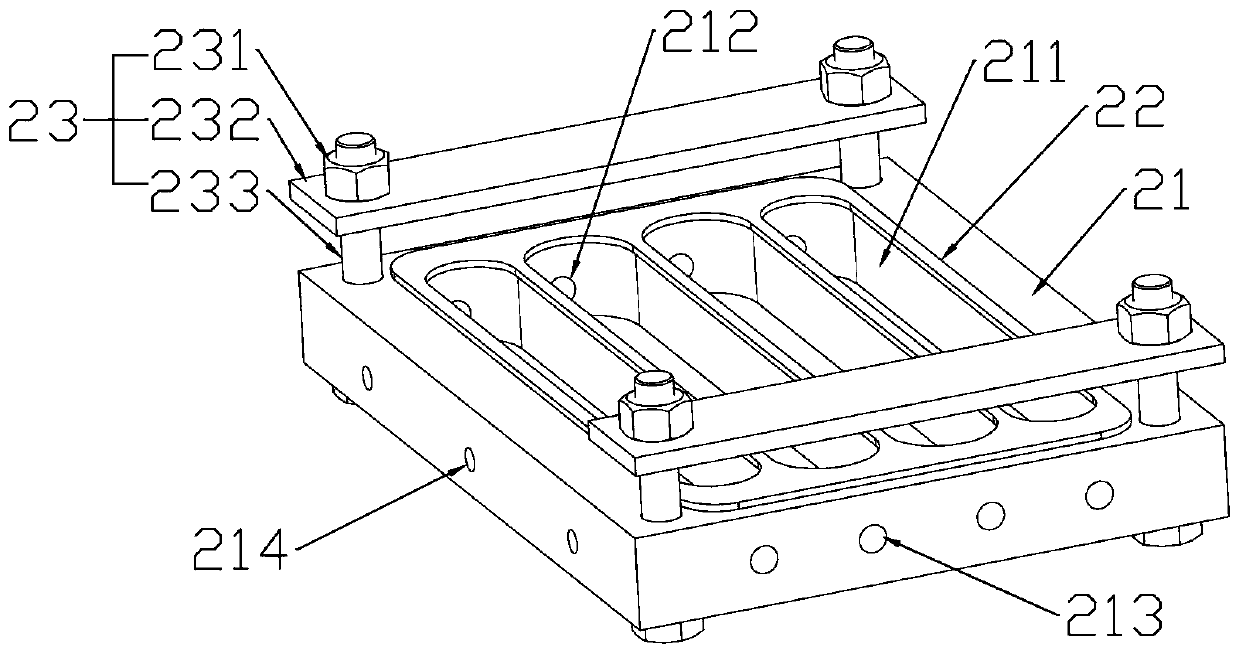

[0027] A semi-open atmosphere protection and water cooling device for laser cladding, comprising an atmosphere protection box 1, a water cooling assembly 2 and an air blowing assembly 3. The atmosphere protection box 1 is fixed on a test bench through a supporting leg 13; The water-cooled component 2 is fixed to the supporting foot 13 at the bottom of the atmosphere protection box 1 through the fixed threaded hole 214 on the water-cooled base 21. The surface of the water-cooled base 21 is placed on the substrate for experiment, and the water-cooled base 21 is provided with a plurality of The water flow groove 211 is used to realize the rapid cooling of the substrate; a plurality of the air blowing components 3 are fan-shaped and fixed on both sides of the atmosphere protection box 1, and the air blowing components 3 are located above the water cooling components 2 to achieve omnidirectional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com