Oil storage tank area fire explosion risk assessment method based on fuzzy fault tree

A technology of fuzzy fault tree and oil storage tank area, applied in the field of risk assessment, which can solve the problems of failure mode without accurate assessment and life analysis, ill-considered risk, and inability to perform stress analysis and calculation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] The present invention provides a fire and explosion risk assessment method for oil storage tank farms based on fuzzy fault tree, and the assessment steps are as follows:

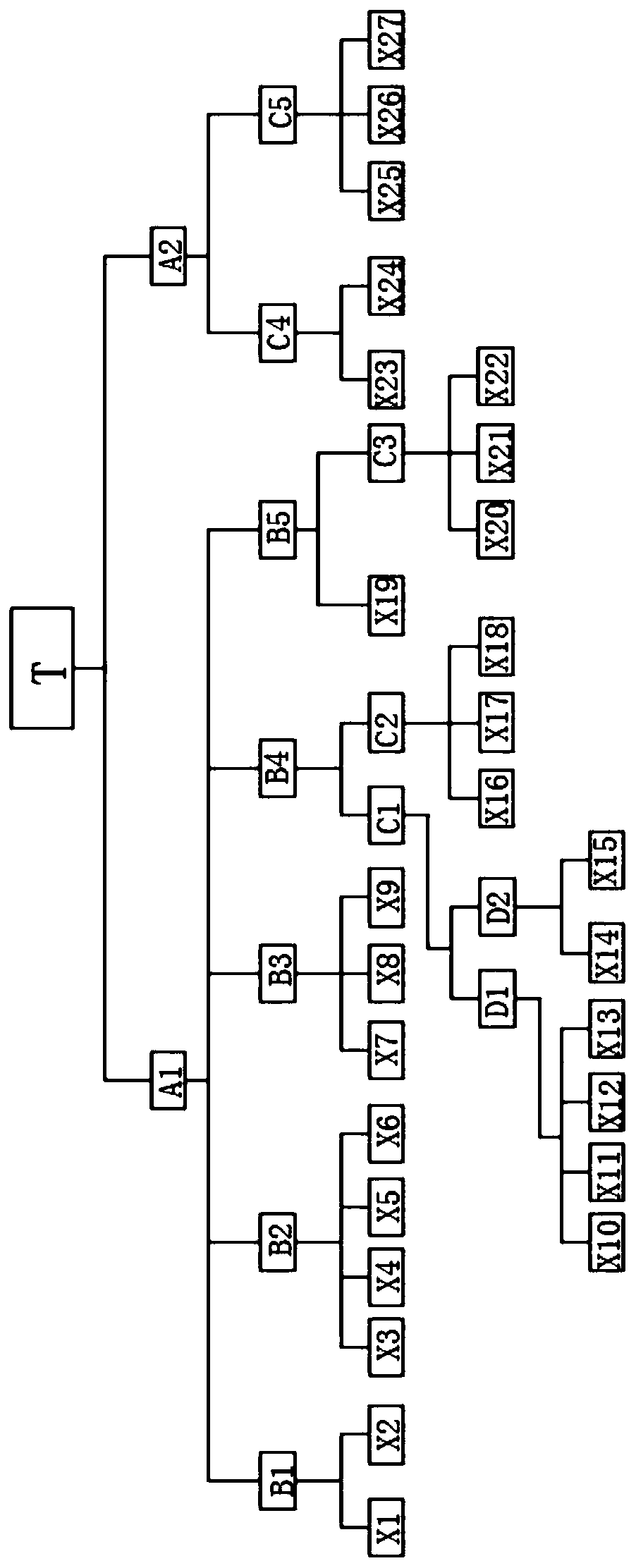

[0070] S1: Fault tree analysis, starting from a possible event, analyzing the triggering event, direct cause and indirect cause of the accident layer by layer, and analyzing the mutual logical relationship of these accident causes, using a logic tree diagram to connect these causes and their The logical relationship is expressed, and the analysis steps are as follows:

[0071] S1.1: In the preparation stage, determine the system to be analyzed, reasonably determine the boundary conditions of the system, be familiar with the system, fully understand the operation status or production process of the system, investigate accidents, and collect data on previous accidents of the system, including attempted failures Accidents, analyze the past, present and future possible failure modes of the system, and the...

Embodiment 2

[0122] A fire and explosion risk assessment method for oil storage tank farms based on fuzzy fault tree, the assessment steps are as follows:

[0123] Carry out fault tree analysis on the oil storage tank area, the specific steps are as follows:

[0124] Firstly, the top event is determined. The main types of accidents in the oil storage tank area are fire and explosion, and the consequences of the general accident are very serious, so the combustion and explosion accident in the oil storage area is taken as the top event;

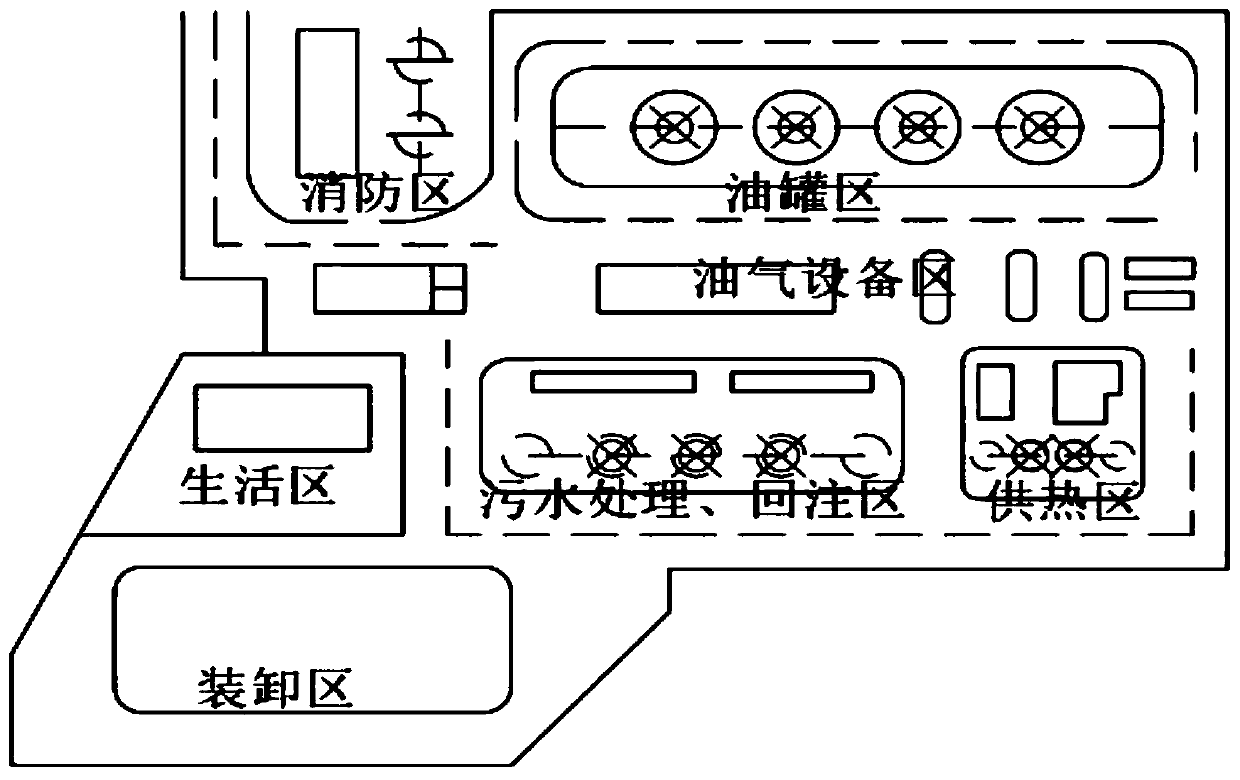

[0125] Then analyze the cause of the accident, see figure 1 As shown, there are three conditions that cause a fire in the oil storage tank area: combustible substances, ignition sources, and oxygen. Combustible substances are mainly oil vapor formed by oil leakage and evaporation. Smoking, sparks generated by metal impact, electrostatic discharge, lightning strikes, etc., can cause fire and explosion when combustible substances reach the explosive limit. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com